Functionalized elastomer nanocomposite

A technology of nanocomposite materials and elastomers, which is applied in the field of nanocomposite materials for airtight layers, and can solve the problems that the applicability of nanocomposite materials has not been proven or disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

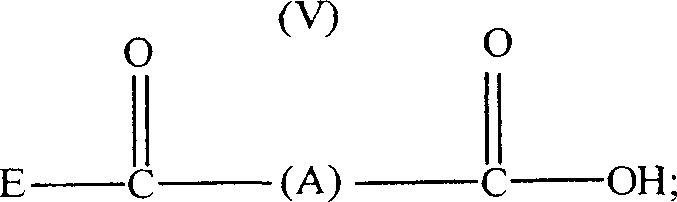

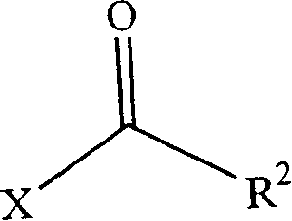

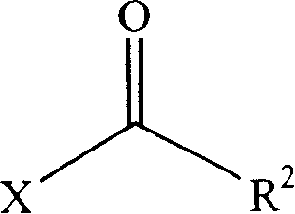

Method used

Image

Examples

Embodiment

[0120] The present invention will be better understood by referring to the following examples and tables, but the invention is not limited by said examples.

[0121] As a comparative example (Example 1), the permeability of an isobutylene-p-methylstyrene copolymer ("XP 50") containing 11.5 wt% p-methylstyrene units based on the weight of the polymer was measured. The permeability data are summarized in Table 2.

[0122] In Example 2, elastomer XP-50 (55 g) containing 11.5 wt % p-methylstyrene and succinic anhydride (3 g) were dissolved in dichloromethane (CH 2 Cl 2 )middle. Add AlCl to the solution 3 (8g). After stirring for 1.5 hours, the solution was poured into methanol containing 120 mmol HCl to yield a functionalized elastomer. The functionalized elastomer (40.5 g) was then melt blended in a Brabender at 160°C, followed by the addition of Cloisite 6A clay (4.5 g) and mixing for 10 minutes. Samples of this composition were pressed into films for testing permeability....

Embodiment 3

[0124] For Example 3, XP 50 (55 g) containing 11.5% p-methylstyrene and succinic anhydride (1.0 g) were dissolved in dichloromethane. To this solution was added AlCl 3 (2.7g). After stirring for 1.5 hours, the solution was poured into methanol containing 100 mmol HCl, and the resulting product was washed with acetone and dried under vacuum overnight. The modified product was then melt blended in a Brabender at 160° C. and mixed with 4.5 g of clay (Cloisite 6A) for 10 minutes at a rotor speed of 60 rpm. A sample of this composition was tested for permeability and the data are summarized in Table 2.

Embodiment 4

[0125] For Example 4, XP 50 (75 g) with 11.5% p-methylstyrene and succinic anhydride (1.03 g) were dissolved in CH 2 Cl 2 middle. To this solution was added AlCl 3 (2.8g). After stirring for 1.5 hours, the solution was poured into methanol containing 100 mmol HCl, and the resulting product was washed with acetone and dried under vacuum overnight. The functionalized elastomer was then melt blended in a Brabender at 160° C. and mixed with 4.5 g of clay (Cloisite 6A) for 10 minutes at a rotor speed of 60 rpm. A sample of this composition was tested for permeability and the data are summarized in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com