Method for realizing silicon based silicon dioxde waveguide polarization irrelevancy by employing non-planar process

A silicon dioxide, non-planar technology, used in optical waveguides, light guides, optics, etc., to solve problems such as polarization insensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

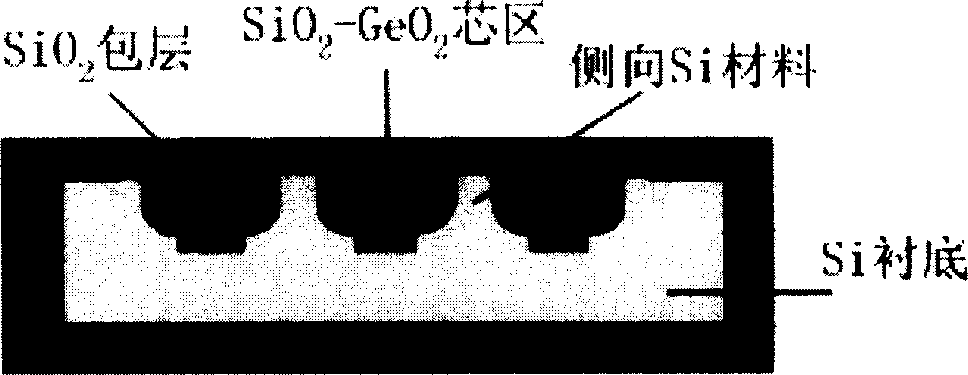

[0022] see image 3 , Figure 3-1 , image 3 -2 is to perform reactive ion etching (RIE) on the silicon substrate 11 first, etch out the square waveguide core space 12, the space width is 22.8 μm, the etching depth is not less than 21 μm, and the core space spacing is not less than 30 μm ; Figure 3-3 A lower cladding layer and lateral cladding layer 13 with a thickness of about 15 μm are formed by high-temperature thermal oxidation to limit light leakage; Figure 3-4 The core region 14 is grown by plasma enhanced chemical vapor deposition (PECVD) or flame hydrolysis (FHD) in the core space of the waveguide, the thickness of the core layer is controlled to 6 μm, and the refractive index is 0.75 according to the difference between the refractive index of the core region and the cladding layer. % to determine, the core material can be P 2 o 5 -GeO 2 -SiO 2 、GeO 2 -SiO 2 , SiON or P 2 o 5 -SiO 2 ; image 3 -5 is to use the FHD method or the PECVD method to grow the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com