Process control hierarchy analog steel rolling system

A technology of process control level and simulator, which is applied to the simulation process of specific applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

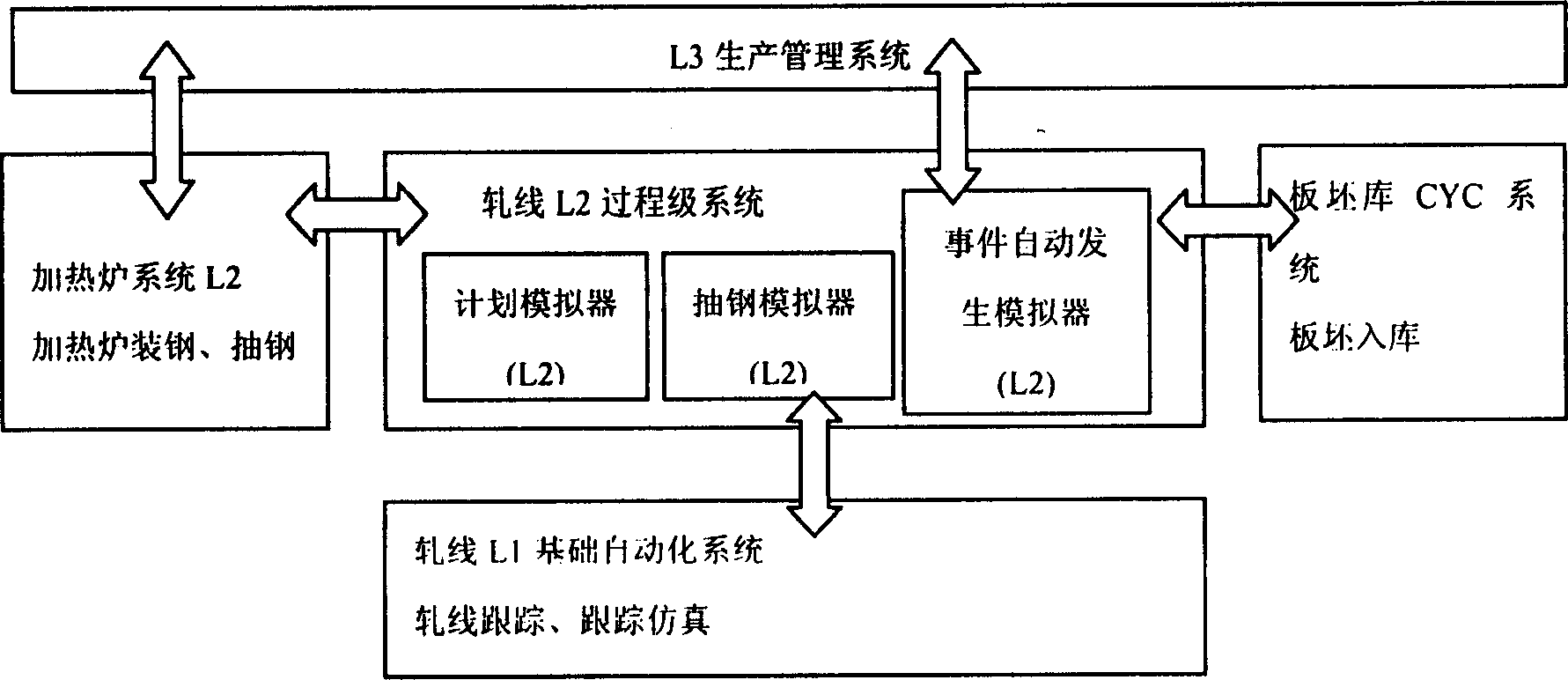

[0019] Such as figure 1 , 2 Shown:

[0020] The simulated steel rolling system of the present invention comprises:

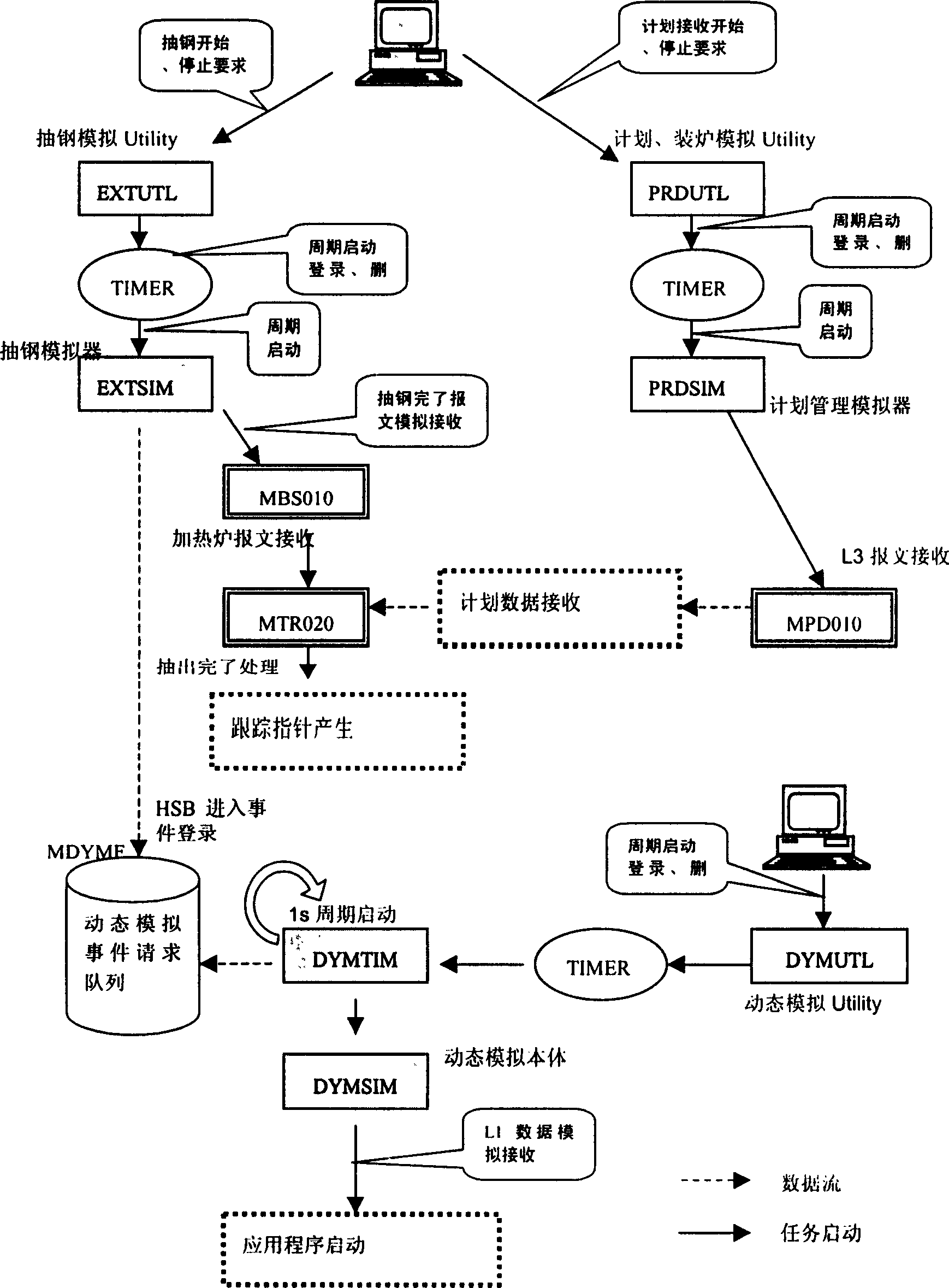

[0021] A plan simulator, which includes a simulator body (PRDSIM) for receiving messages by the plan simulator and a command interaction tool module (PRDUTL) for the plan simulator;

[0022] Steel pumping simulator, which includes the simulator body (EXTSIM) of the steel pumping simulator receiving message and the steel pumping simulator command interaction tool module (EXTUTL);

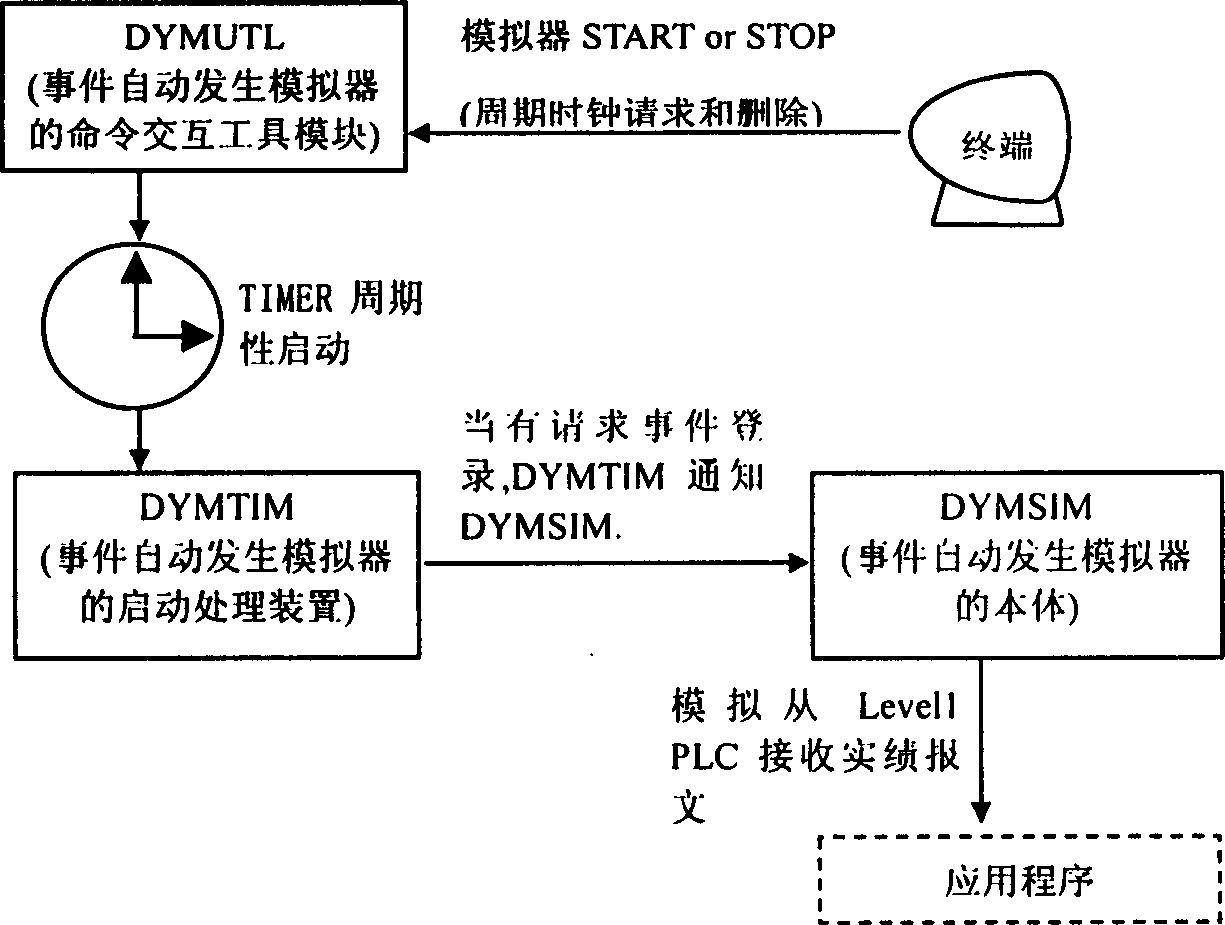

[0023] The event automatic occurrence simulator includes a simulator body (DYMSIM) of the event automatic occurrence simulator, a start-up processing device (DYMTIM) of the event automatic occurrence simulator, and a command interaction tool module (DYMUTL) of the event automatic occurrence simulator.

[0024] Firstly, the rolling plan data message from L3 (production management system) is simulated periodically through PRDUTL (plan simulator command interaction tool software) and P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com