Scraping-pressing device for integrated circuit and method thereof

An integrated circuit, pressure technology, applied in the direction of circuits, identification devices, electrical components, etc., can solve the problems of damage, difficult to adjust the parallelism of the track, difficult to maintain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

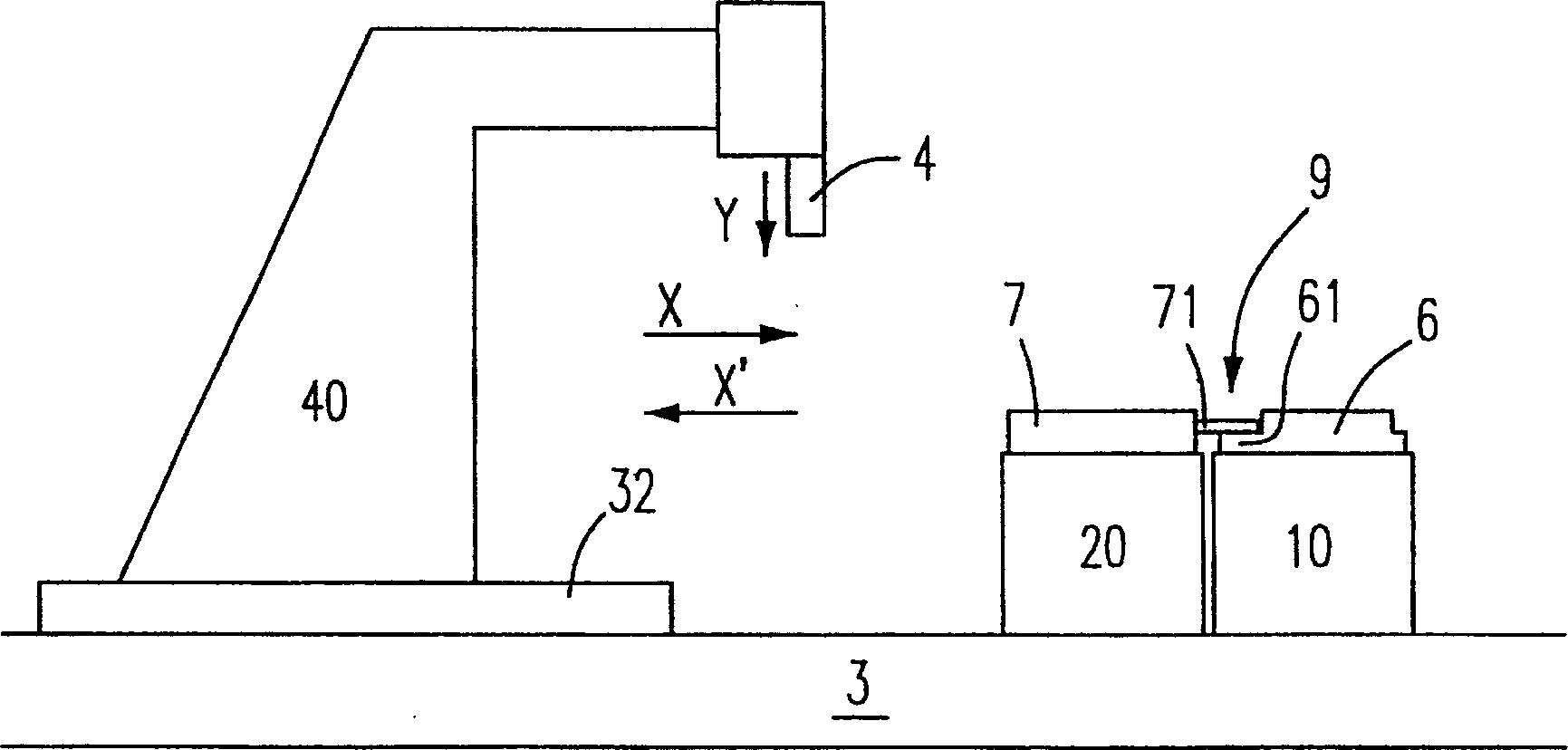

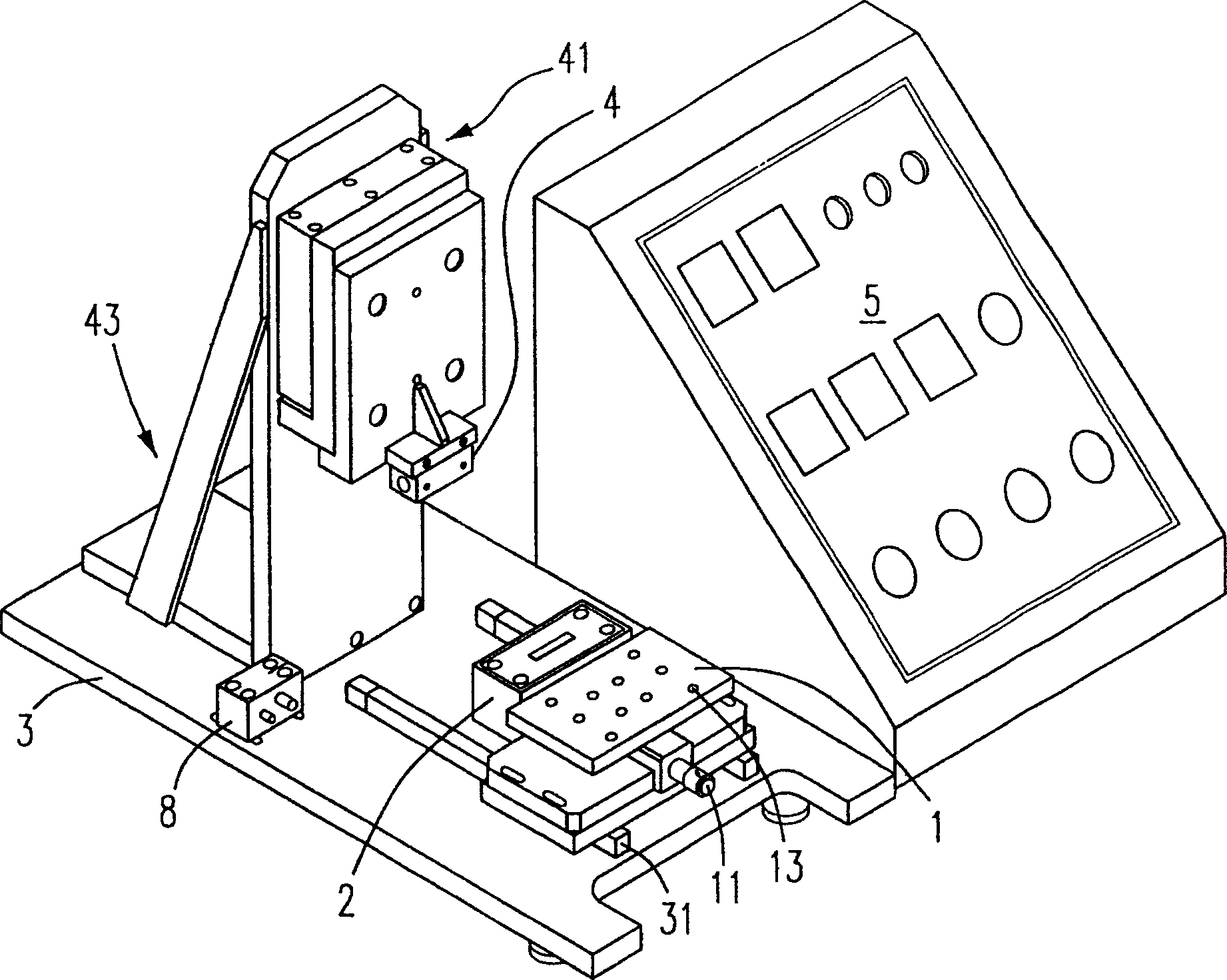

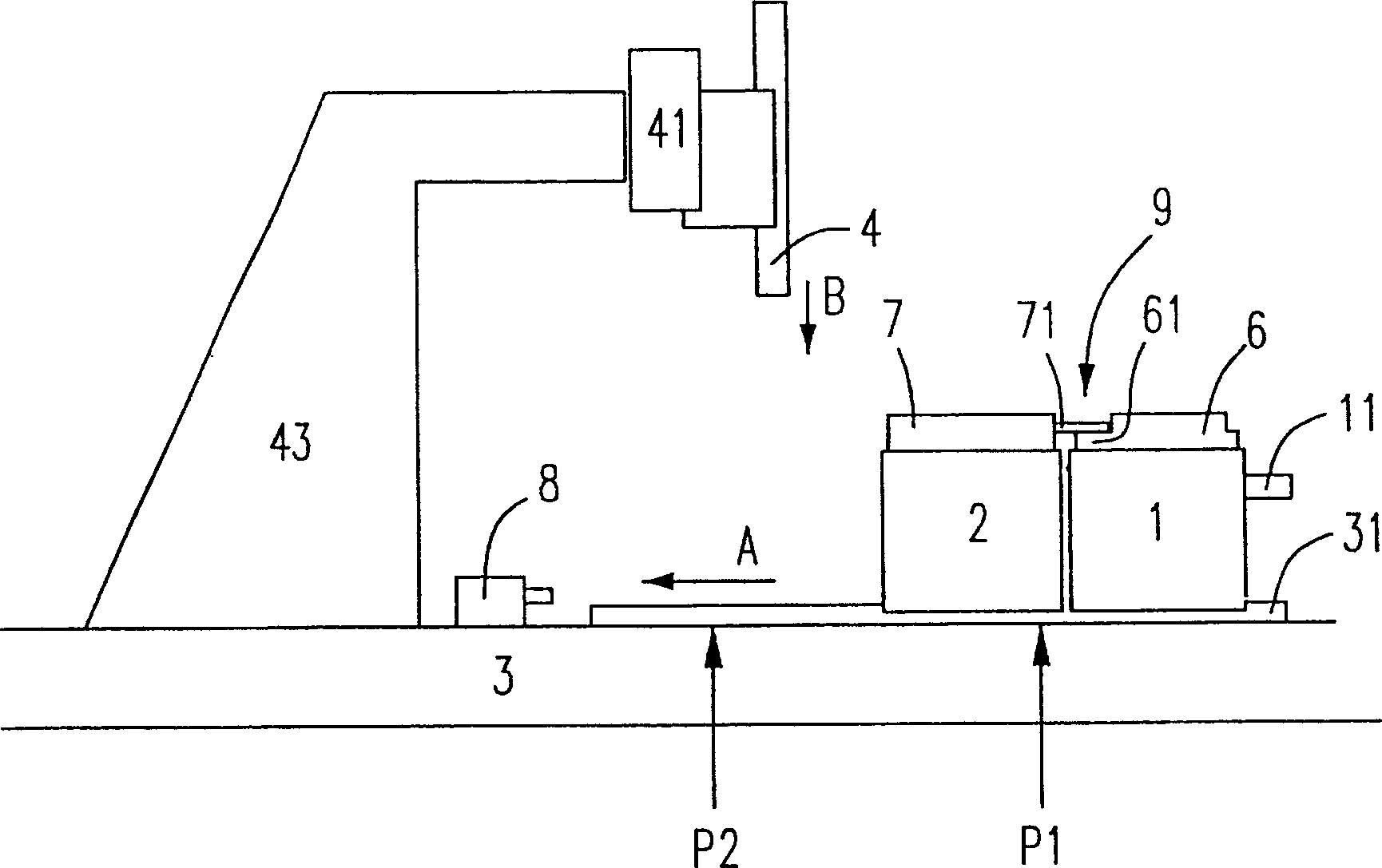

[0034] Please see first figure 2 , is a three-dimensional schematic diagram of the present invention, including a base 3 for scraping and pressing operations, and a suction table 1 is arranged on the base 3, and the suction table 1 can move horizontally on the base 3, and also That is to approach or stay away from a cantilever 43 arranged on the base 3; the cantilever 43 is provided with an upper hook head 4, so that the upper hook head 4 can be suspended on the suction table 1, and the upper hook head 4 generally uses The moving method is vertically up and down, approaching or away from the suction table 1; in addition, a locator 2 is arranged on the base 3, and the locator 2 moves along the base 3 together with the suction table 1.

[0035] read on figure 2, in order to enable the positioner 2 and the suction table 1 to be accurately positioned, a positioning adjuster 8 is also provided on the base 3 to precisely adjust the positions of the positioner 2 and the suction ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com