Cages for Radial Roller Bearings

A roller bearing and cage technology, which is applied in the field of cages for radial roller bearings, can solve problems such as easy skew and instability, and achieve the effect of inhibiting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

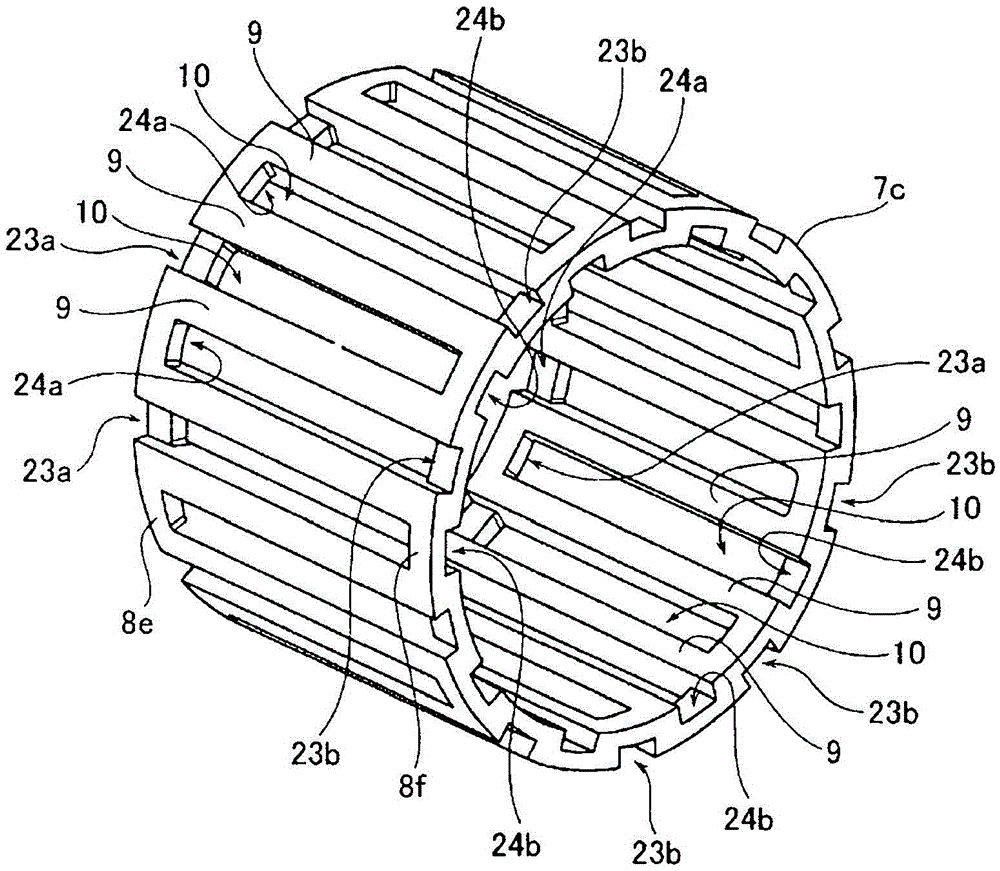

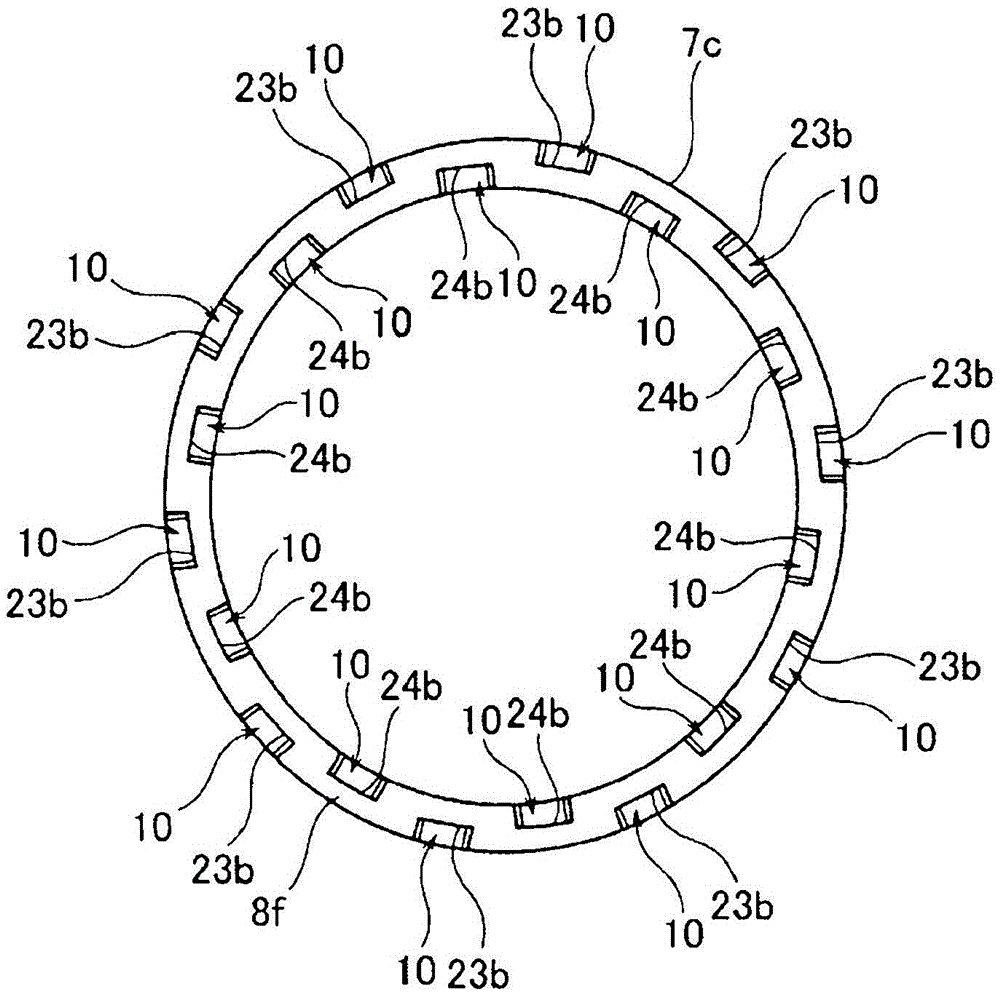

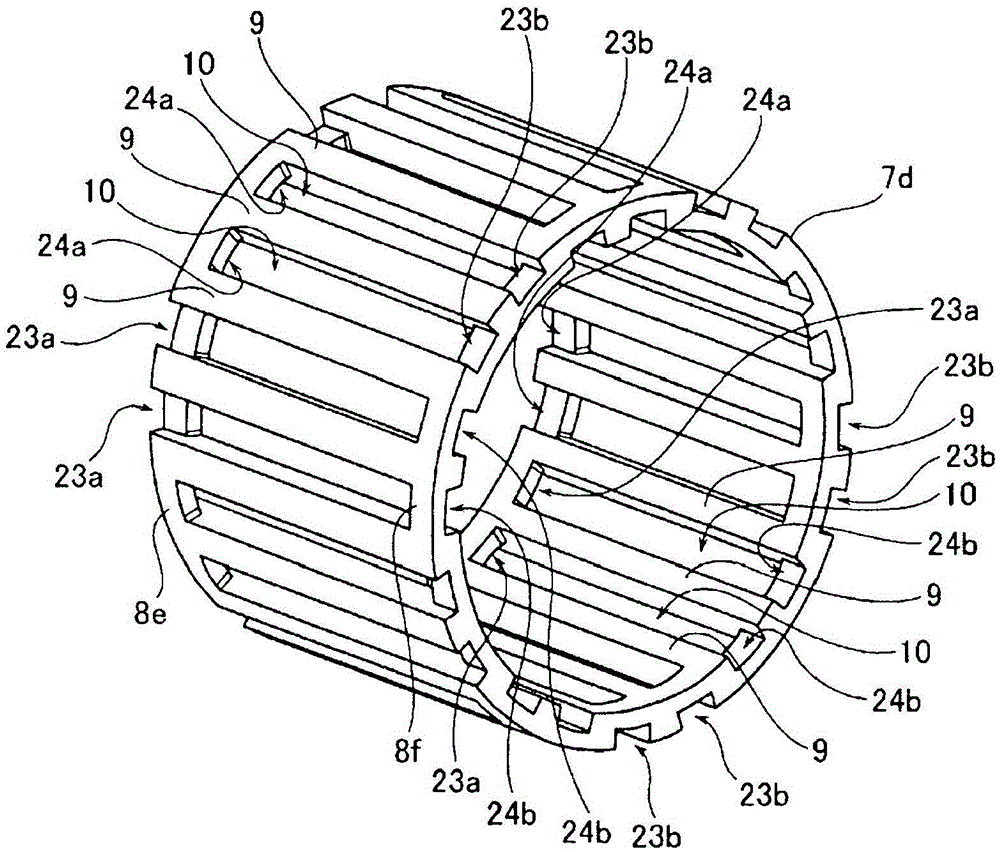

[0090] Next, a cage for a radial roller bearing according to the present invention will be described with reference to the drawings. The radial roller bearing incorporating the cage for radial roller bearing of the present invention is equipped with an outer diameter side member having a cylindrical outer ring track on the inner peripheral surface (an outer member that does not rotate during use). Rings, bearing housings, or gears, rollers, etc. that rotate during use); the inner diameter side member that is arranged on the inner diameter side of the outer diameter side member and has a cylindrical inner ring track on its outer peripheral surface (the inner ring that rotates during use , a rotating shaft or a support shaft that does not rotate during use, etc.), and a plurality of rollers (including needle rollers) that are freely rotatable provided between these outer ring tracks and inner ring tracks. In addition, the size of the radial roller bearing, the presence or absenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com