Weight-light ligh-emitting diode unit

A technology of light-emitting diodes and white light, applied in luminescent materials, electrical components, sustainable buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

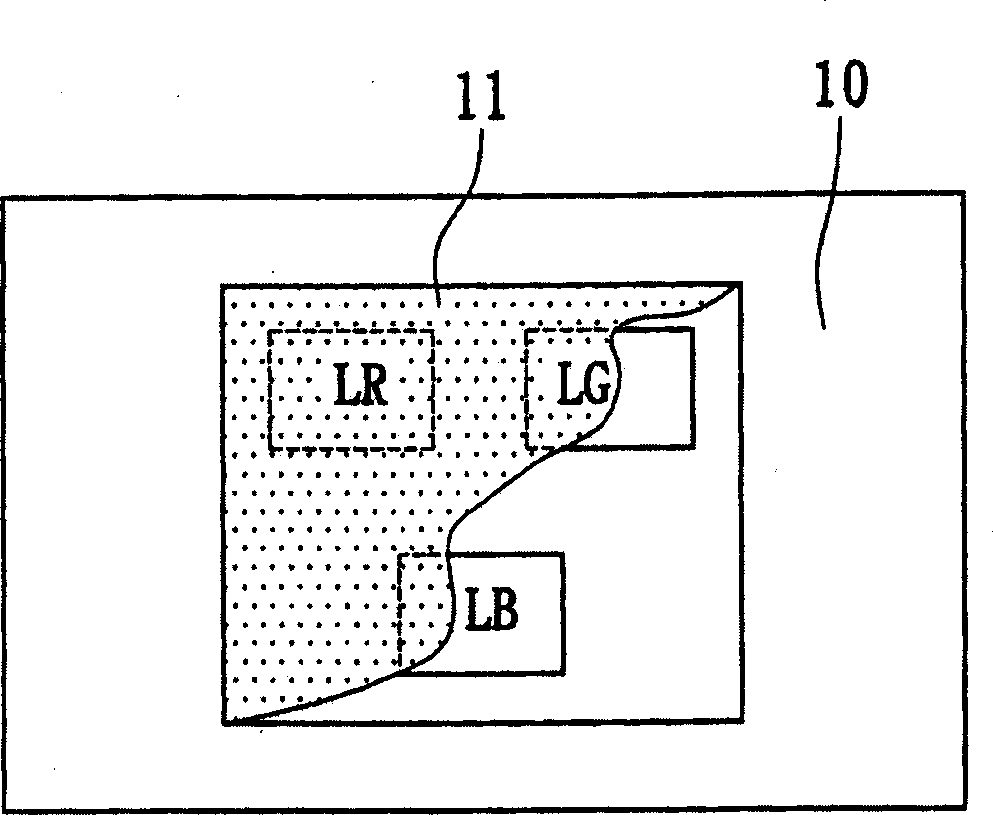

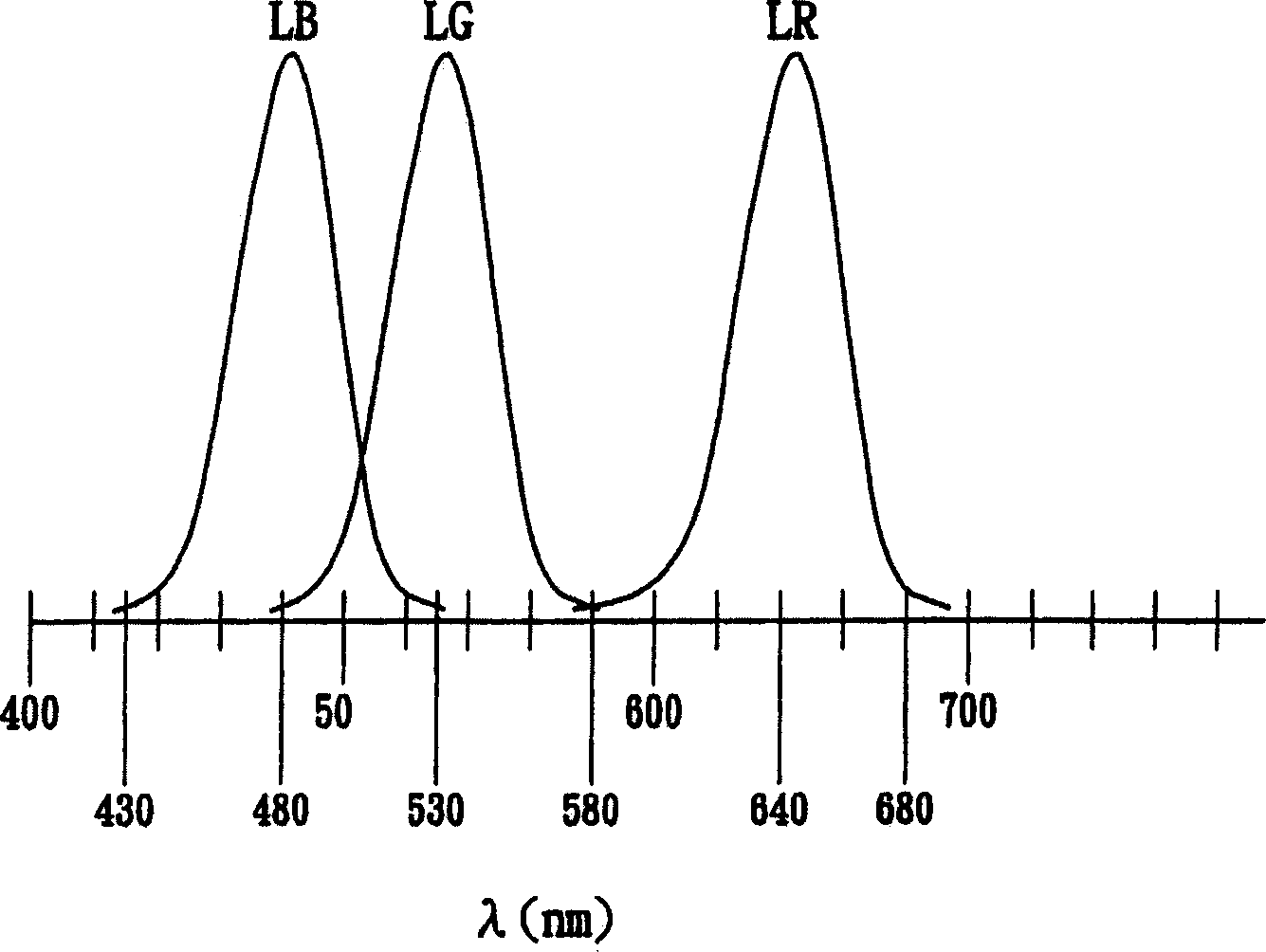

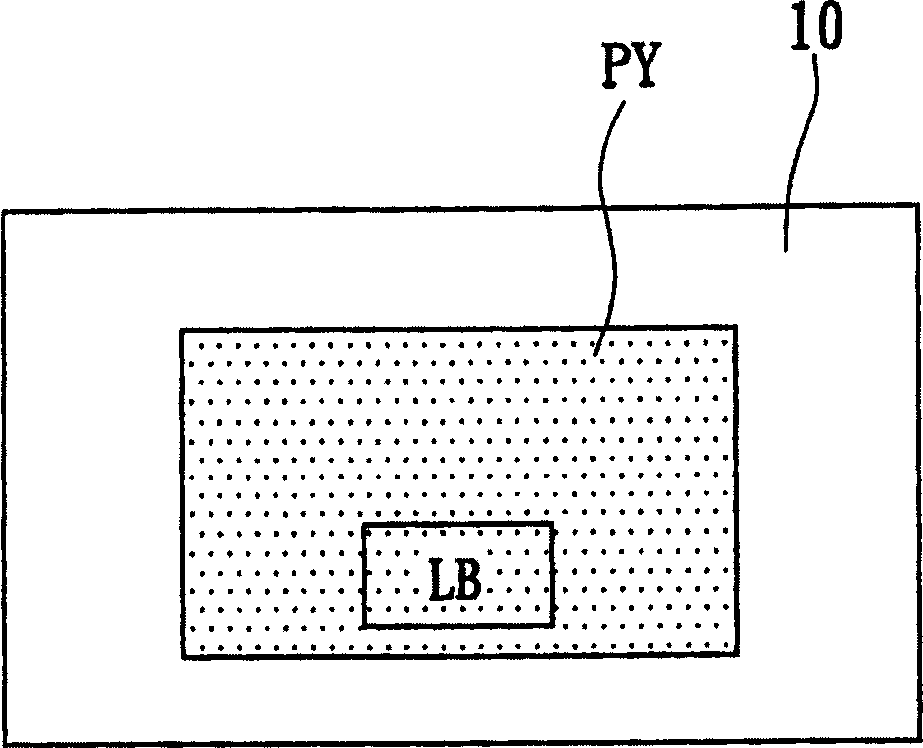

[0014] Such as image 3 Shown is a schematic diagram of a white light emitting diode unit 2 according to a preferred embodiment of the present invention. The white light emitting diode comprises a substrate 20, a blue light emitting diode LB positioned on the substrate 20, and a red phosphor PR and a green phosphor PG positioned on the blue light emitting diode LB, the red phosphor PR and the green phosphor The phosphor PG can absorb the blue light of the blue light-emitting diode LB to emit red light and green light respectively, and mix with the blue light of the blue light-emitting diode LB to form white light.

[0015] Among the red and green phosphors described above, the red phosphor can use Cas:Eu or SrS:Eu; the yellow silver phosphor can use YAG:Ce or TbAG:Ce; and the green phosphor can use SrGa 2 S 4 : Eu or Ca 8 EuMnMg(SiO 4 ) 4 C 12 . However, it should be noted that there are other phosphors that can be used besides the above-mentioned phosphors, but it does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com