Method of manufacturing substrate having resist film

A manufacturing method and resist film technology, applied in the field of substrate manufacturing, can solve the problems of small resist film thickness uniformity and insufficient resist film thickness uniformity, so as to reduce film thickness distribution and improve thickness uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Hereinafter, examples of the present invention will be described in detail.

[0087] (Structure of coating device)

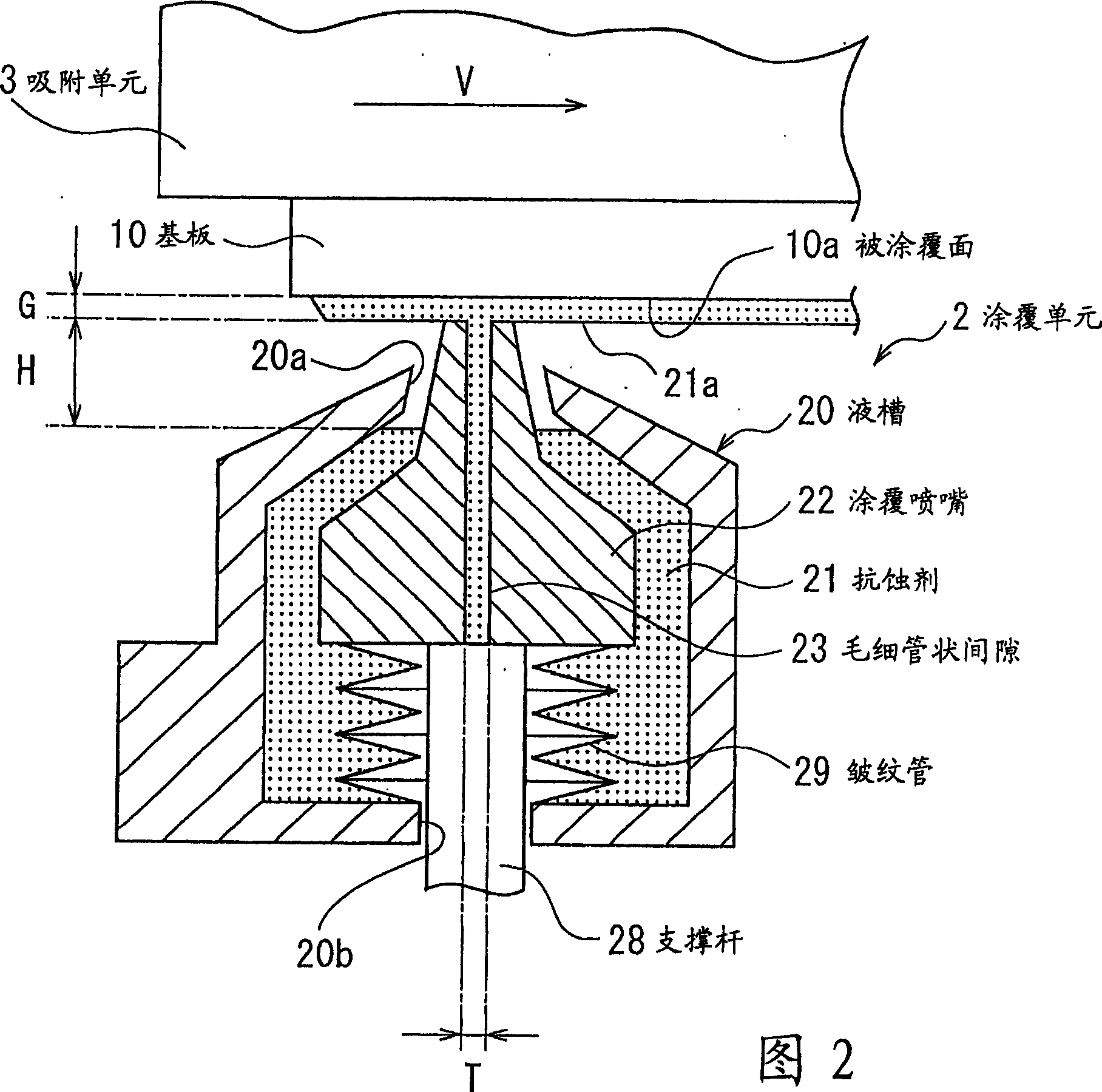

[0088] In describing embodiments of the present invention, reference is first made to Figure 5 ~ Figure 8 The structure of the coating apparatus equipped with the mechanism which holds the board|substrate 10 which has the surface to be coated 10a of this invention and is movable with respect to the coating nozzle 22 is demonstrated. In this coating apparatus, the resist 21 is applied to the substrate 10 by the method of manufacturing a substrate with a resist film according to the present invention.

[0089] Figure 5 is a side view showing the structure of the coating device.

[0090] Such as Figure 5 As shown, the coating device has: a base frame 11; a coating unit 2 disposed on the base frame 11; movably supported on the base frame 11 and can be moved in a horizontal direction by a moving unit 4 The mobile frame 12; the adsorption unit 3 provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com