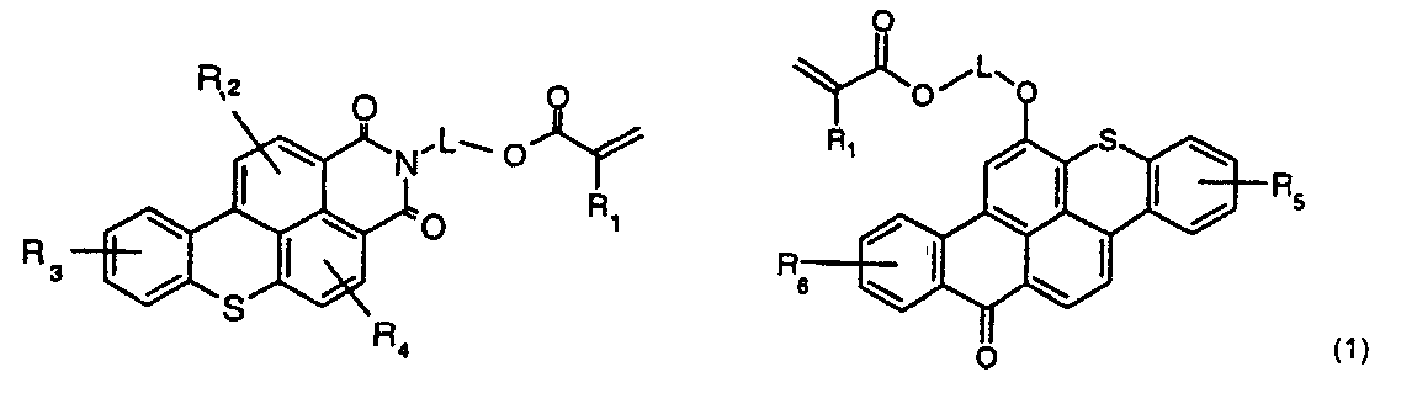

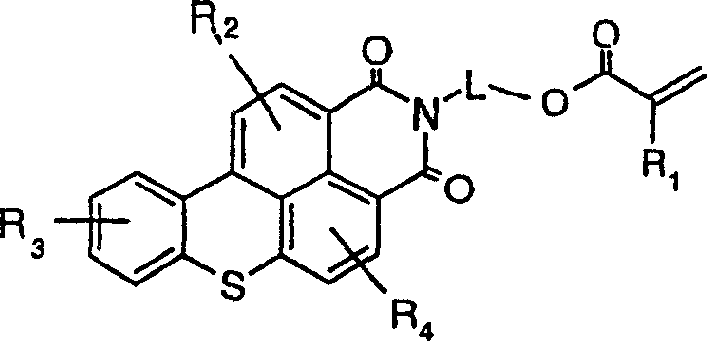

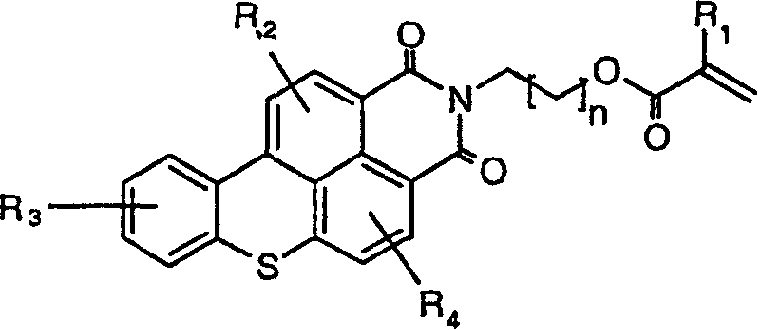

Functional fluorescent dyes

A compound, methyl technology, applied in the field of fluorescent dyes, can solve the problems of no compatibility, poor solubility, limited, etc., and achieve the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0188] A 600 mL Parr reactor (obtained from Parr Instrument Co., Moline, IL) was charged with MeFBSEA (146.30 g; 0.36 mol), MeFBSEMA (10.03 g; 0.023 mol), BMA (3.34 g; 0.023 mol), LMA ( 5.85 g; 0.023 mol), MAA (1.67 g; 0.020 mol) and AD-1 (0.011 g). After the material had dissolved, LUPEROX (9.24 grams) and HFE-7100 (440.80 grams) were added. The reactor was then sealed, vacuumed to 5-10 psig (34-68 kPa), degassed four times, and then purged with nitrogen. The reactor temperature was raised and maintained at 80°C for approximately 24 hours. The solution obtained by filtration is used to coat the substrate to be tested.

Embodiment 2

[0190] Example 2 was prepared as described in Example 1, except that AD-2 was used instead of AD-1, and the AD-2 / polymer mass was gently heated to 80°C in an oven.

Embodiment 3

[0192] Example 3 was prepared as described in Example 1, except that AD-3 was used instead of AD-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com