Intelligent monitoring and control method for coagulation process based on multisource information fusion technology

A multi-source information fusion and intelligent monitoring technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems that cannot fully reflect raw water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

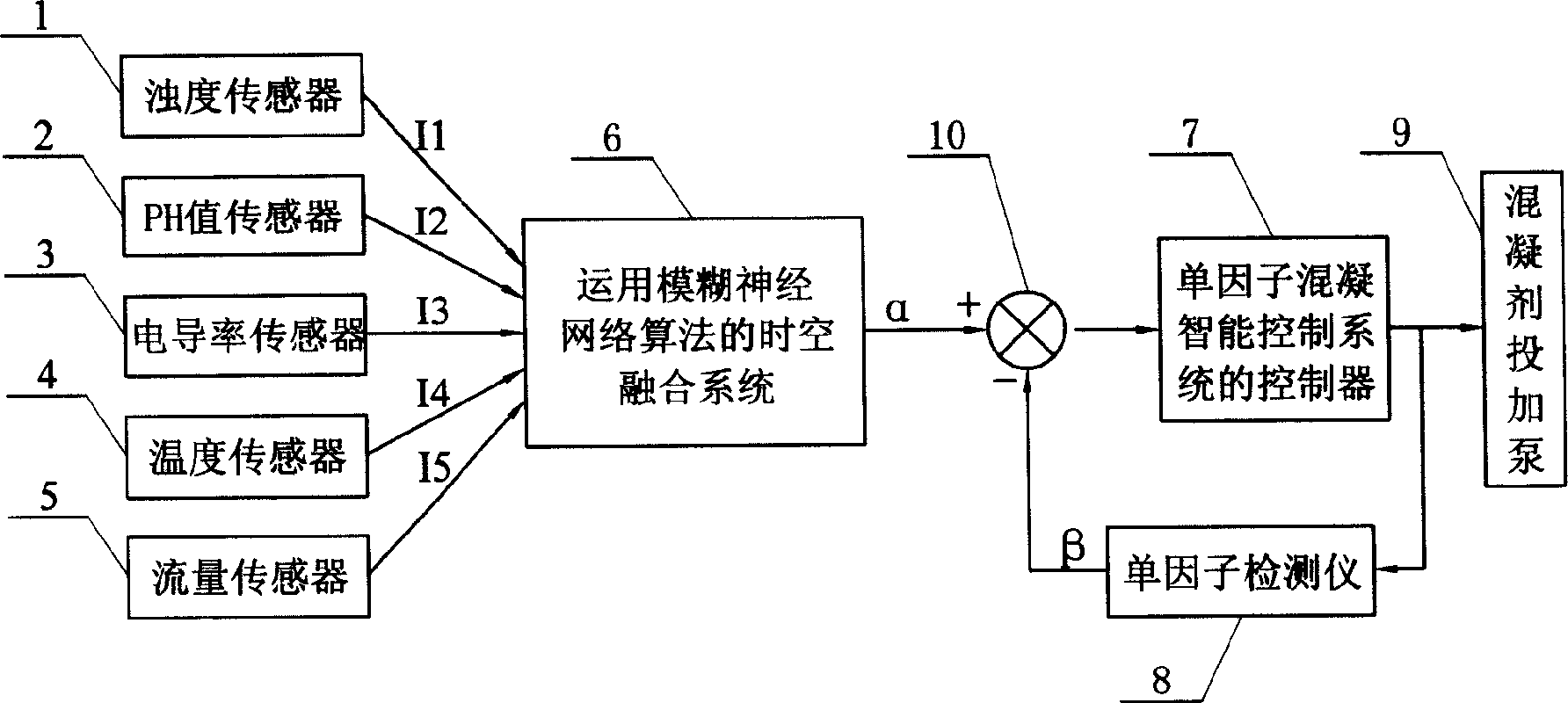

[0005] Specific embodiment one: this embodiment is made up of the following steps: one, utilize the turbidity sensor 1 that is arranged on raw water, pH value sensor 2, conductivity sensor 3, temperature sensor 4 and flow sensor 5 to obtain respectively the corresponding water quality parameter Signals I1, I2, I3, I4 and I5; step 2, input the corresponding signals I1, I2, I3, I4 and I5 representing water quality parameters into the space-time fusion system 6 using fuzzy neural network algorithm, and input the output value α to the comparator The positive input terminal of 10 is used as the setting value of the single-factor coagulation intelligent control system; three, the corresponding operation is performed in the controller 7 of the single-factor coagulation intelligent control system, and the dosage of coagulant is output to the mixing The coagulant dosing pump 9, and the single-factor detector 8 installed in the coagulation reaction tank feeds back the detected current co...

specific Embodiment approach 2

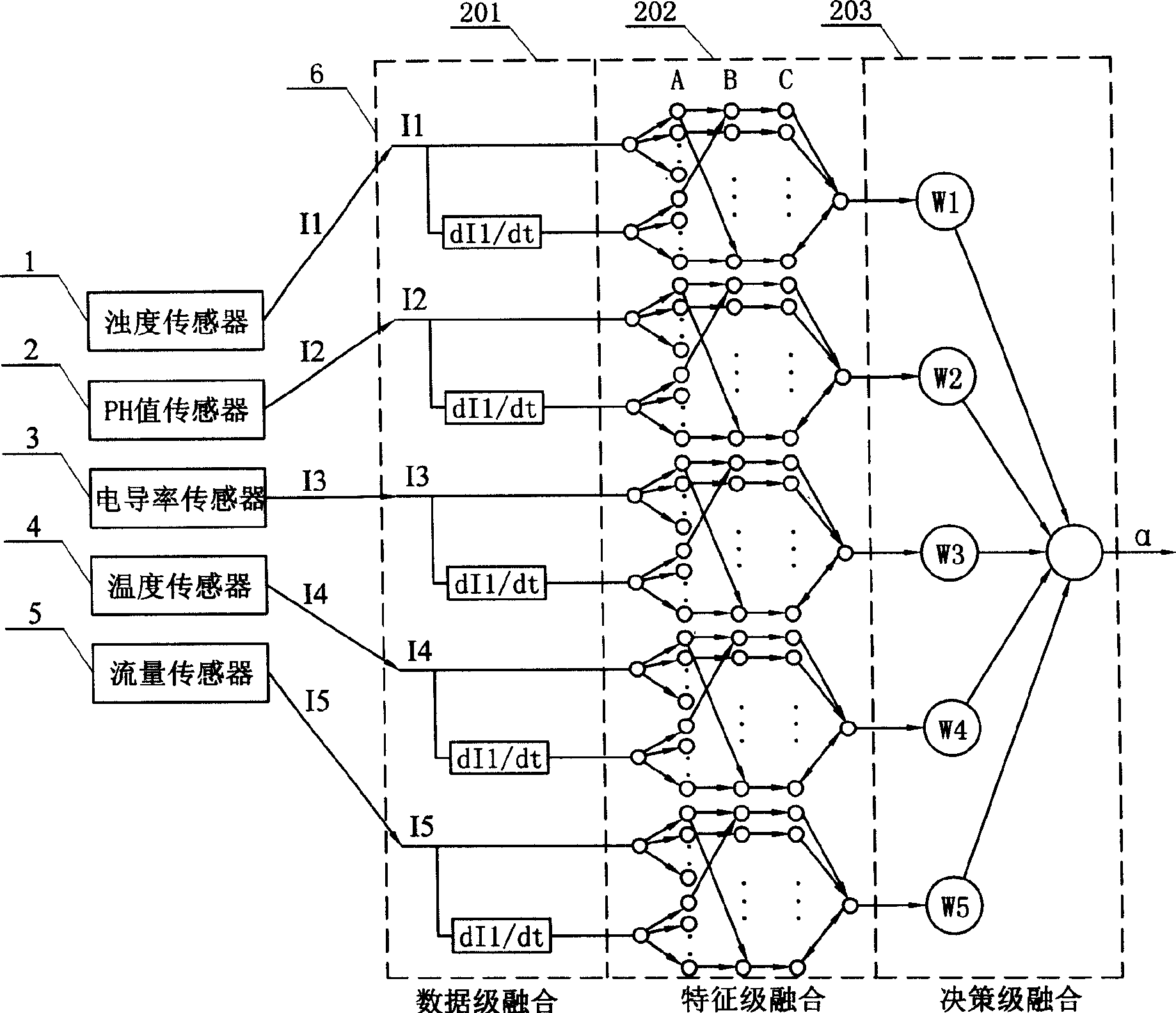

[0006] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that step 2 in Embodiment 1 consists of the following steps: 201. Carry out data-level fusion of the input signals I1, I2, I3, I4 and I5 respectively, that is, obtain the The detection value and the rate of change of the detection value of each sensor are calculated, and the continuous output data of each sensor is analyzed for abnormal changes to determine whether the data is reliable, so as to determine whether the instrument has problems such as failure, noise interference, and signal loss; 202. Carry out feature-level fusion of the data that has been fused at the data level, specifically, use a fuzzy neural network with a 5-layer network structure of two data inputs and one data output to convert the information of different metrics into Consistency description of the degree of coagulation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com