Long type charcoal kiln

A long-shaped, kiln-body technology, used in special forms of dry distillation, petroleum industry, biofuels, etc., can solve the problems of long distance of hot air convection up and down, long production cycle, uneven hot air convection and transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

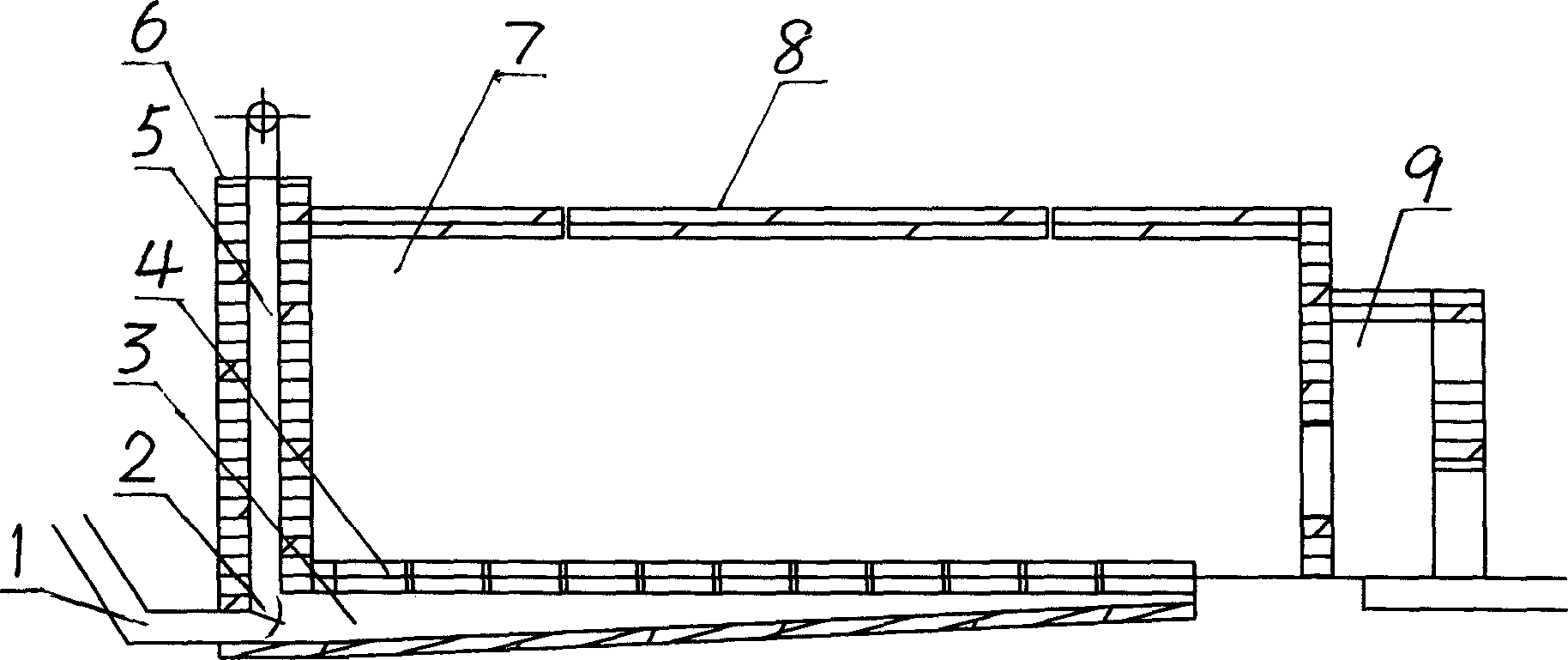

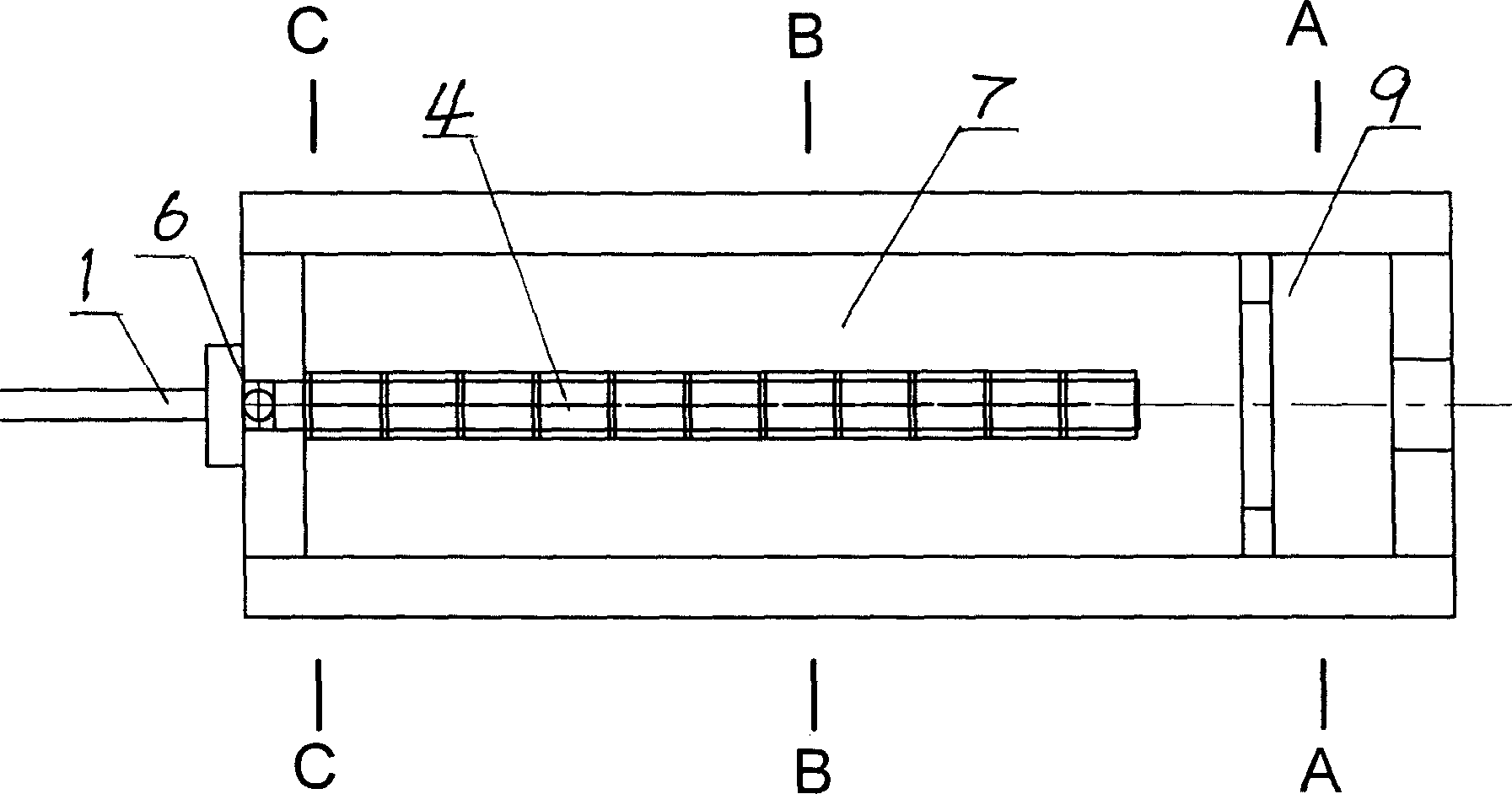

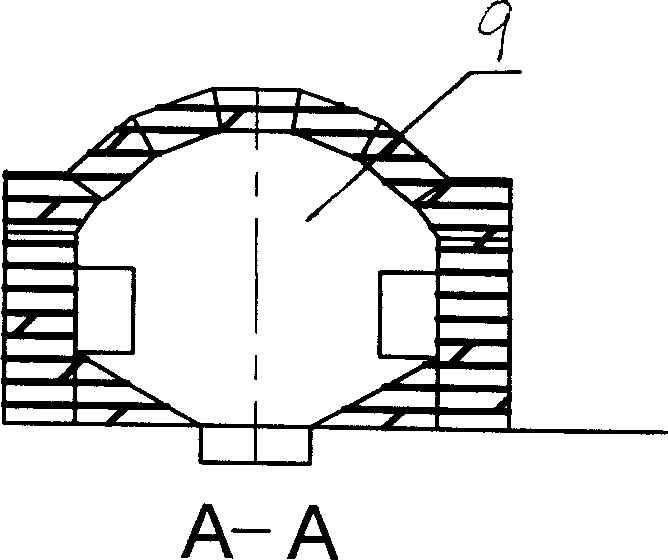

[0009] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings: the front side of the combustion chamber 9 of the kiln body is connected to the air inlet and the fuel input port, and the rear side is connected to the carbonization chamber 7 on the arched top surface, and the carbonization chamber 7 has an inlet and outlet. Mouth 8, so that take out charcoal rod when packing into bamboo, timber and going out kiln by this mouth 8, close temporarily again when burning charcoal. The chimney 6 is at the rear end of the kiln body, and the house is made up of the chimney flue 5 and the chimney mouth. There are indoor flues 3 on the bottom and / or side walls of the carbonization chamber 7. The number and positions of the indoor flue 3 distributions are based on the size of the carbonization chamber. It depends on factors such as length, width, single kiln or multiple kilns in series, and the type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com