Plastic rubber sheet forming and shaping processing method

A processing method and technology for plastic sheets, applied in the field of plastic sheets, can solve problems such as unbearable use, unfavorable manufacturers' competitiveness, and uneven arrangement of plastic molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

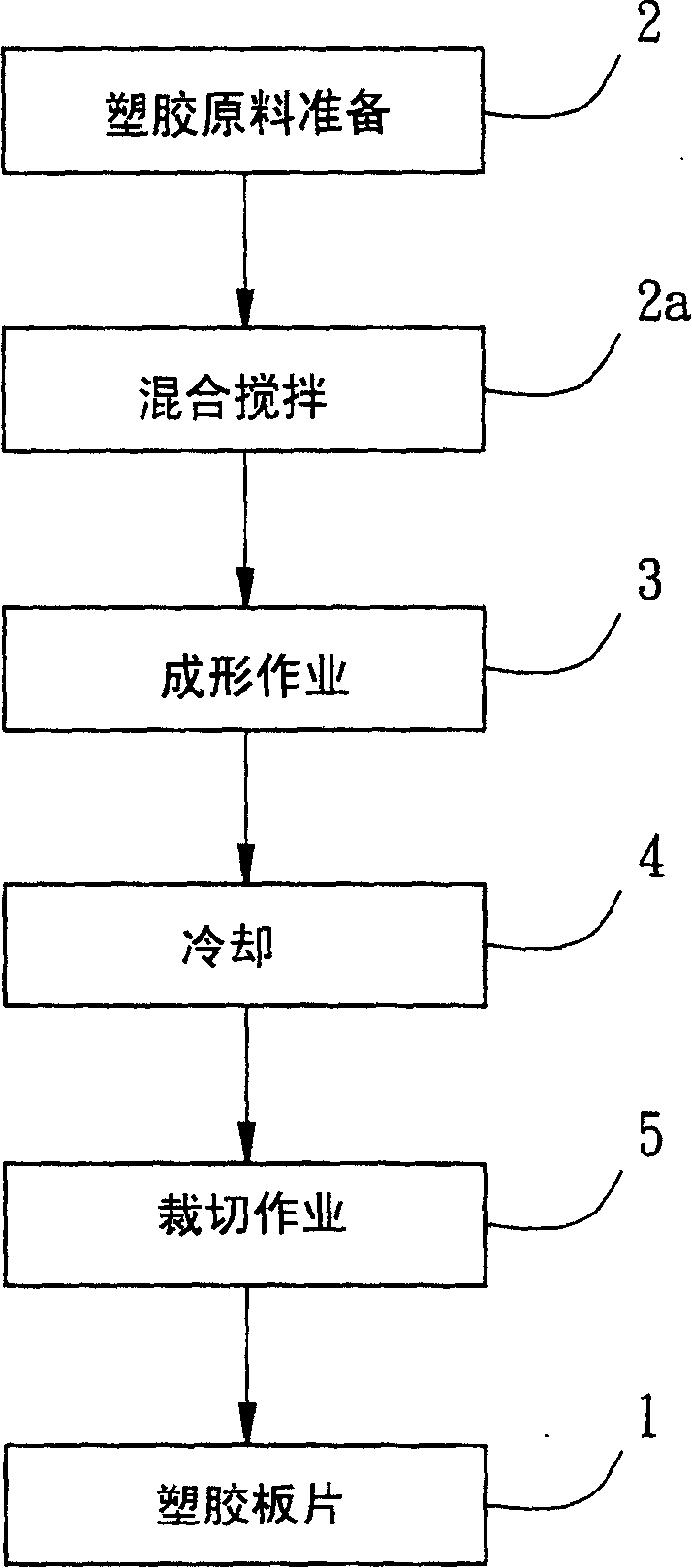

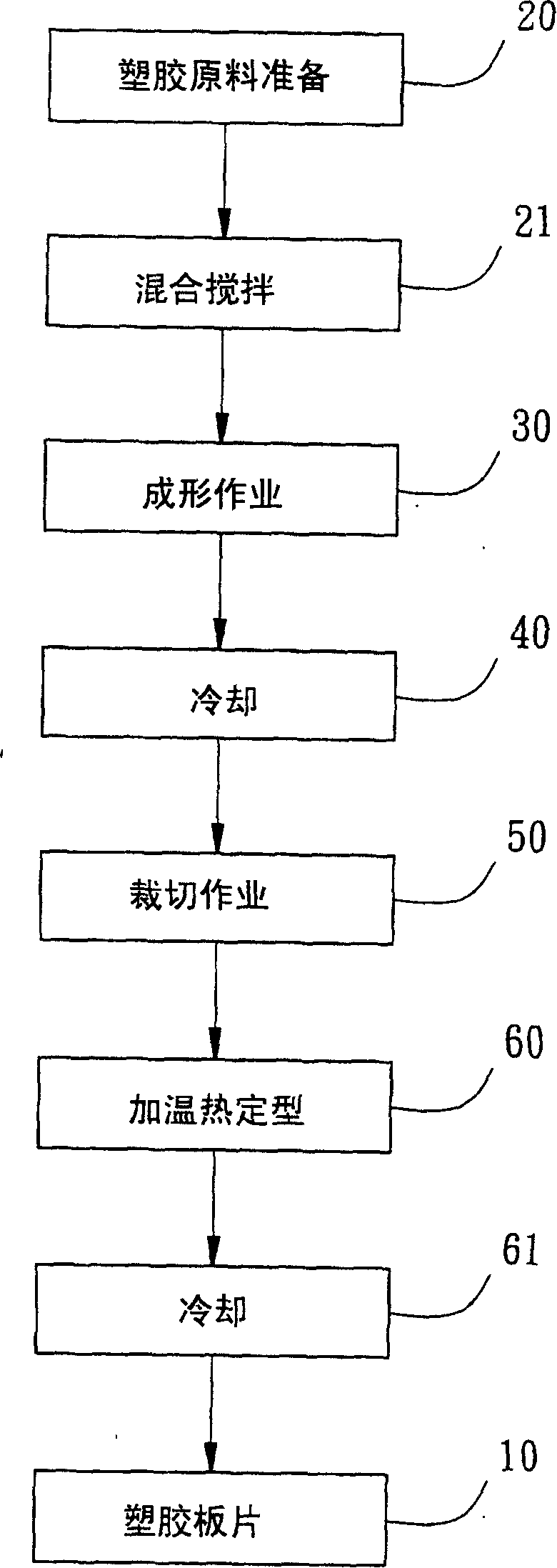

[0025] see figure 2 Shown is a kind of plastic sheet 10 forming and shaping processing method provided by a preferred embodiment of the present invention, and its manufacturing steps are as follows:

[0026] (1) Preparation of plastic raw materials 20:

[0027] After fully mixing and stirring the plastic raw materials required for extrusion 21, inject them into a molding device (it can be an extruder or an injection machine);

[0028] (2) Molding operation 30:

[0029] Heat the plastic material in the molding equipment to soften it, pressurize and push it into a profile mold (if the molding equipment is an extruder, the profile mold is an extrusion mold, if the molding equipment is an injection mold machine, the profile mold is an injection mold);

[0030] (3) Cooling 40:

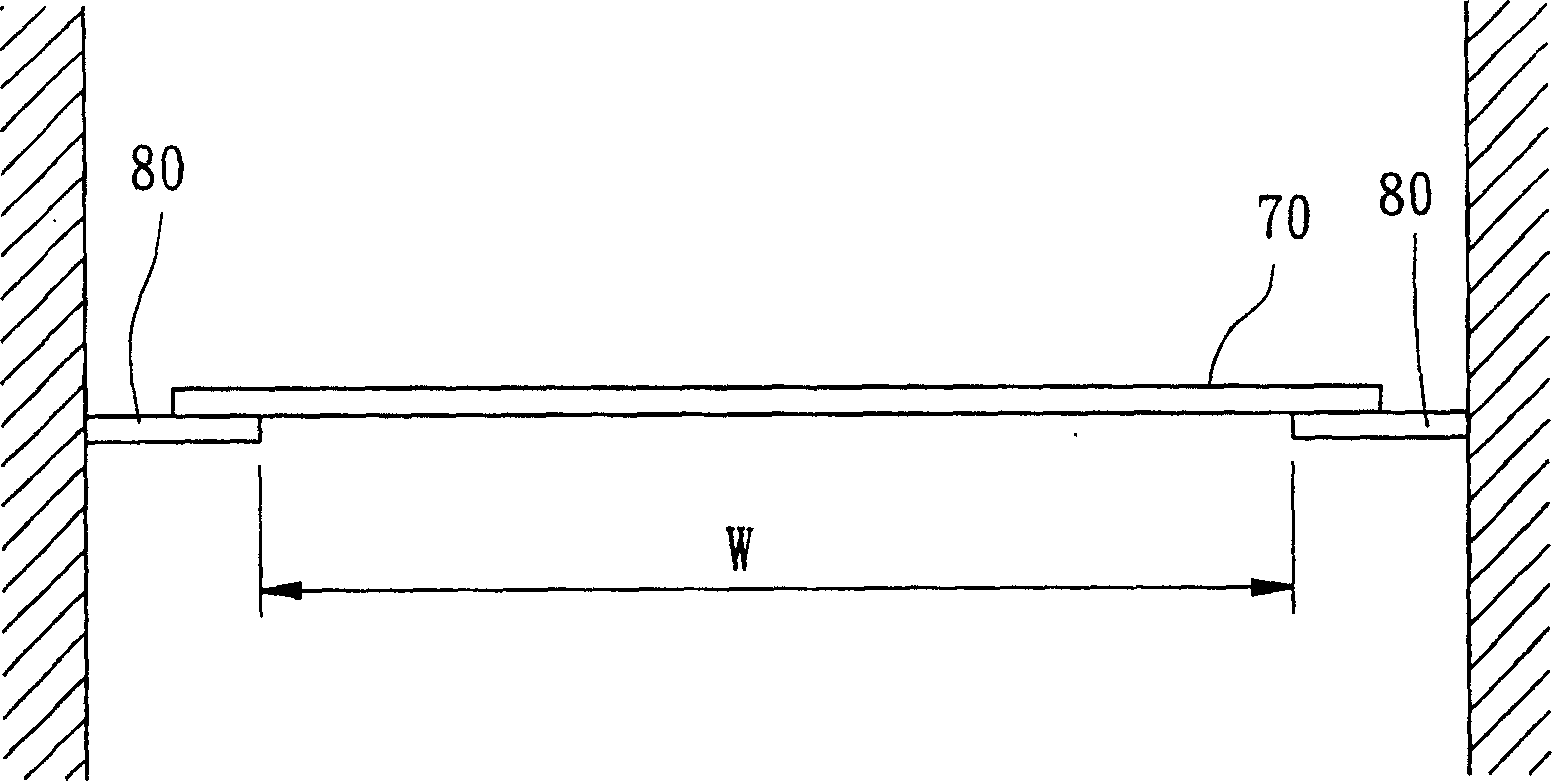

[0031] After the softened plastic material is molded by the molding equipment, it enters a cooling mold through the profile mold, and is solidified and formed by contacting the cooling mold with outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com