Manufacturing method of small sized turbine shaft

A manufacturing method and turbine shaft technology, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems that the roughness of the groove cannot be guaranteed, the supercharger rubs, and the sealing groove cannot be ground out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

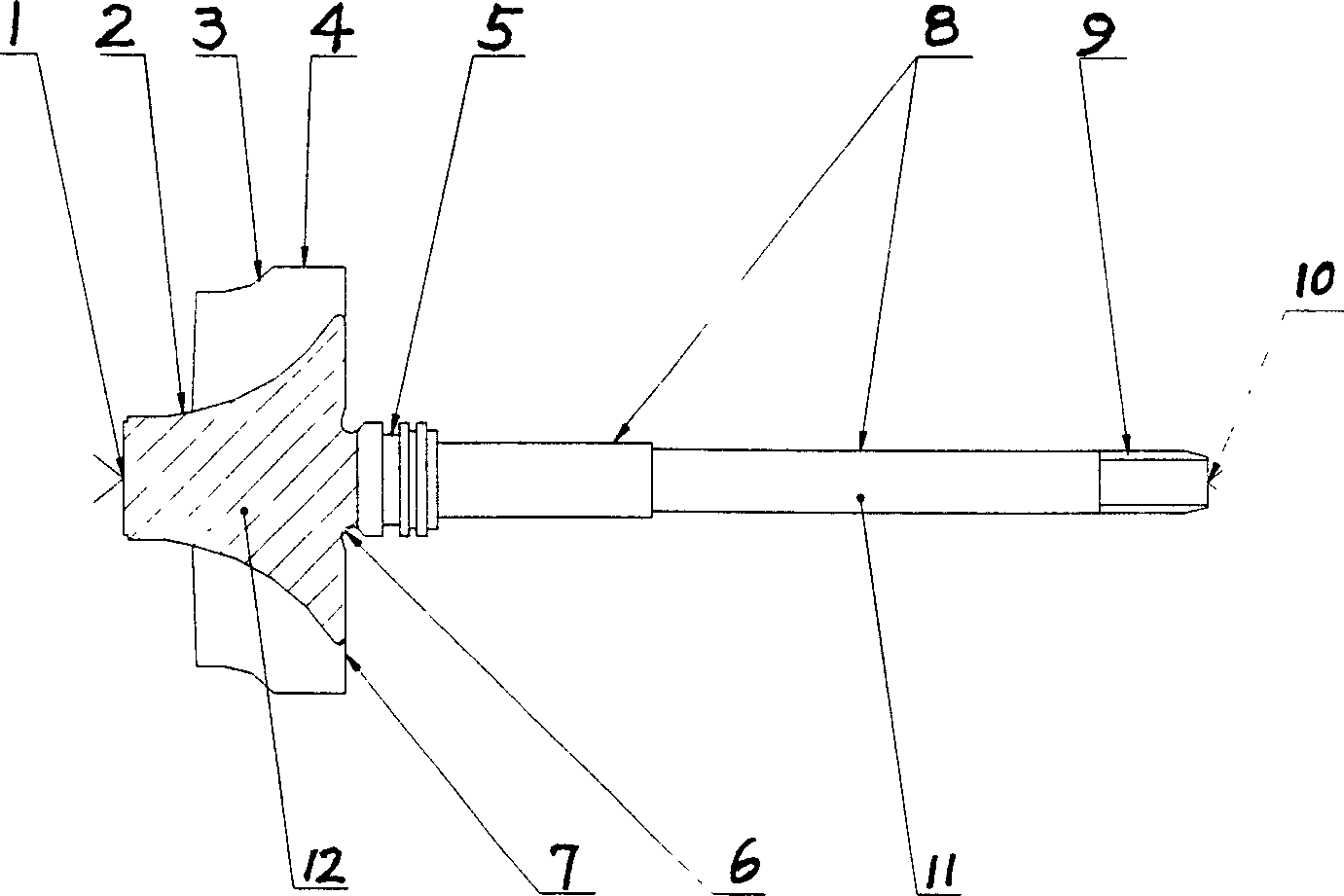

[0010] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] see figure 1 , the manufacture method of a kind of small-sized turbine shaft of the present invention, comprises: (1), turbine 12 and shaft 11 are welded as a whole with friction welding; (2), heat treatment is to eliminate stress; (3), sanding welding place; ( 4), carry out the tensile test; (5), use the clamping ring for the turbine shaft and the three claws to clamp the large outer circle 4 of the turbine, align the end face 7 of the turbine, first turn the welding scar, and then turn the shaft 11 to the required length. Drill the center hole 10 at the shaft end; (6), use the three claws to clamp the top cone surface of the vortex end 2, use the top center hole 10, rough turn each outer circle 4, 8, and turn the R groove 6 to the required size; (7) , color flaw detection; (8), grinding the center hole 1, 10; (9), grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com