Integral permanent-magnet bistable micro electromagnet driver

A bistable, micro-electromagnetic technology, applied in the direction of non-polar relays, circuits, magnets, etc., can solve problems such as power consumption in the state maintenance stage that is difficult to solve, and achieve the effect of state switching and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

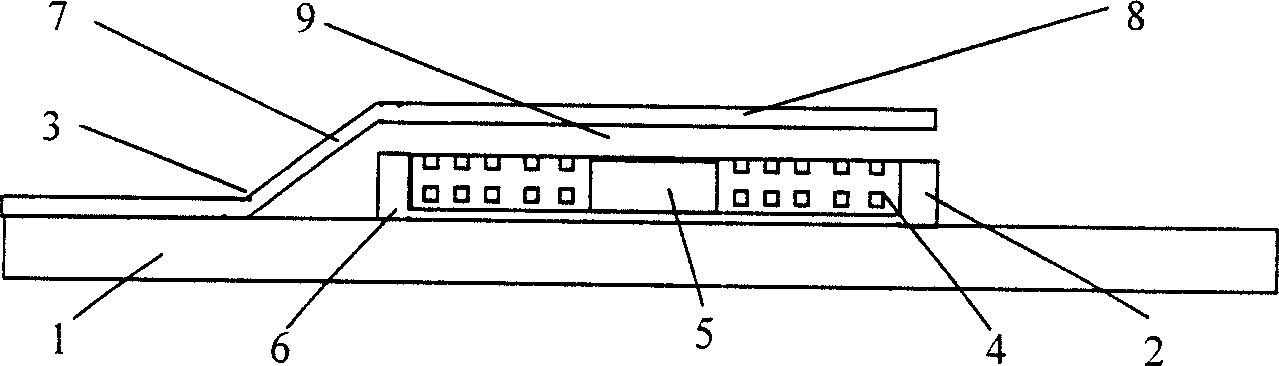

[0014] Such as figure 1 As shown, the present invention includes: a substrate 1, a stator 2, and a mover 3, and the stator 2 includes: a micro-drive coil winding 4, a permanent magnet 5, a soft magnetic yoke 6, and the permanent magnet 5 is located at the micro-drive coil winding 4 In the center, the soft magnetic yoke 6 is located below and around the micro-drive coil winding 4 , the soft magnetic yoke 6 is located below the permanent magnet 5 , and the stator 2 and the mover 3 are fixed on the substrate 1 .

[0015] The micro drive coil winding 4, the central permanent magnet 5 and the soft magnetic yoke 6 are integrated together.

[0016] The mover 3 includes: a micro-cantilever beam 7 and a soft magnetic armature 8 , the soft magnetic armature 8 is fixed above the soft magnetic yoke 6 and the permanent magnet 5 through the micro-cantilever beam 7 on the substrate 1 .

[0017] There is an air gap 9 between the soft magnetic yoke 6 , the permanent magnet 5 and the soft magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com