Method for manufacturing an optical fiber preform by MCVD

A chemical vapor deposition, preform technology, applied in glass manufacturing equipment, manufacturing tools, metal processing equipment and other directions, can solve the problem of no disclosure, and achieve the phenomenon of reducing or decreasing the refractive index, improving bandwidth, and improving optical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

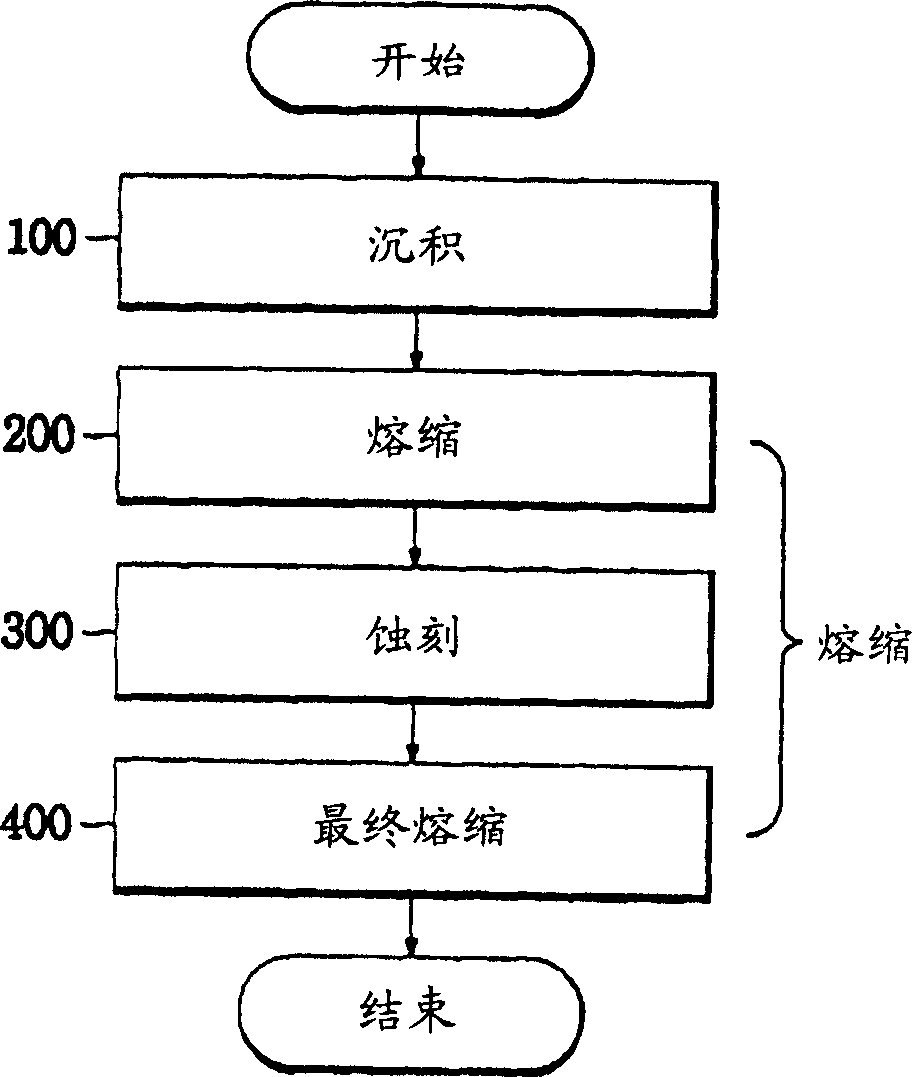

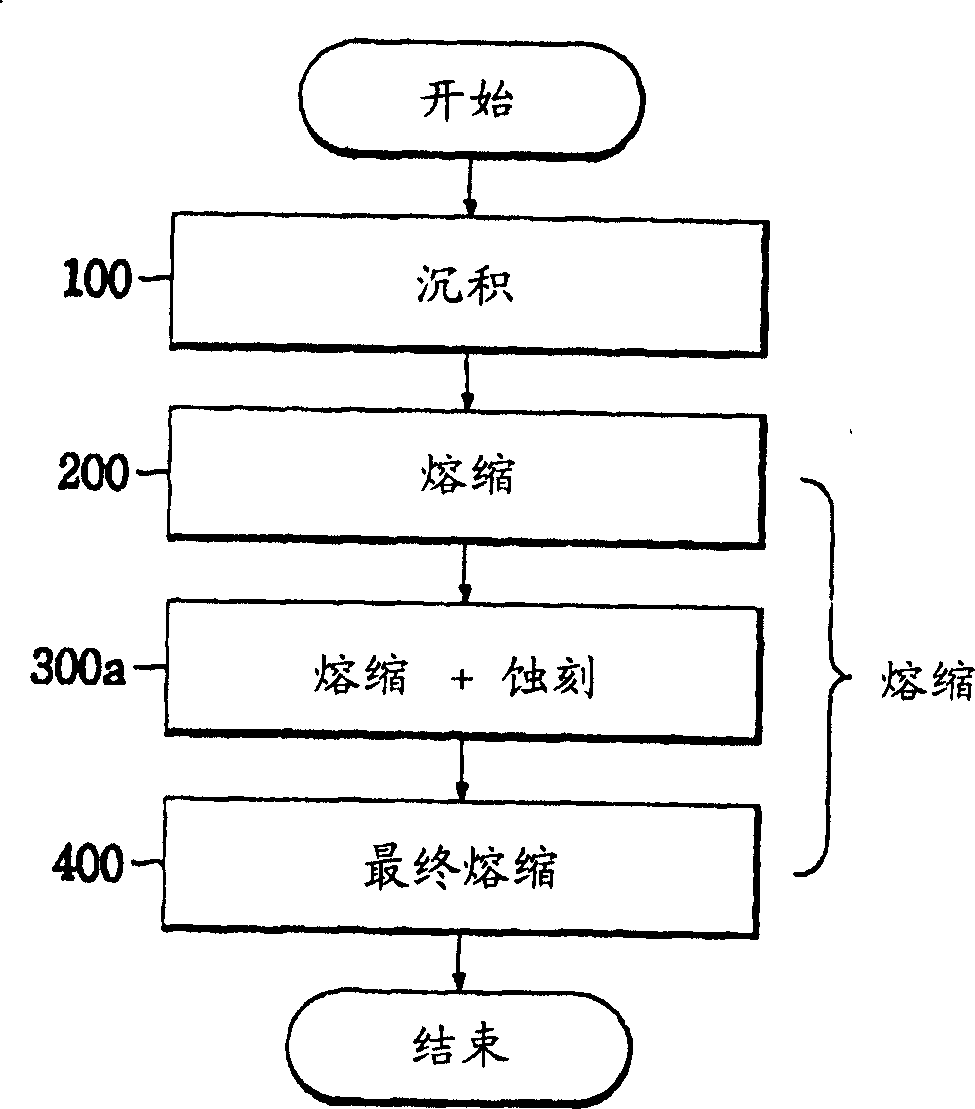

[0036] first, Figure 1b is a flow chart illustrating the method for preparing an optical fiber preform by MCVD (modified chemical vapor deposition) of the present invention;

[0037] refer to Figure 1b , The method for manufacturing an optical fiber preform according to the present invention includes: a deposition step 100 , a shrinkage step 200 , a shrinkage / etching step 300 a and a sealing step 400 .

[0038] Hereinafter, a method for manufacturing an optical fiber preform according to the present invention will be explained step by step with reference to the accompanying drawings.

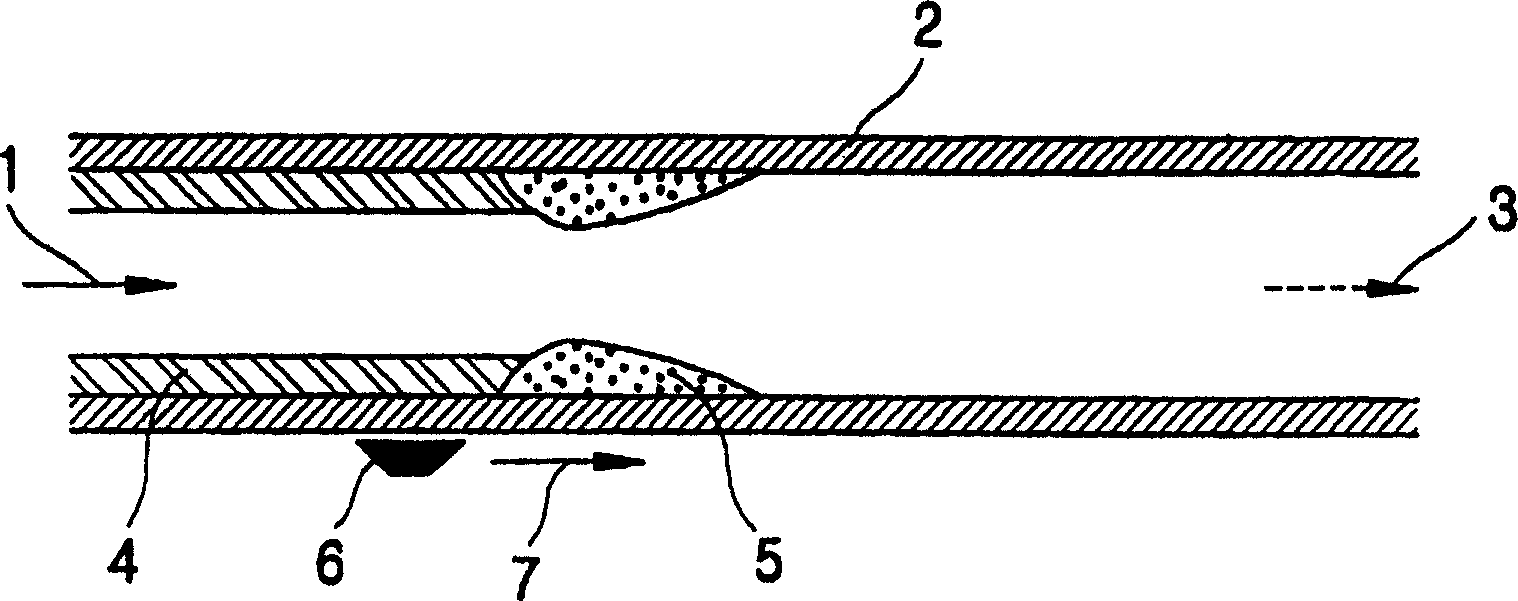

[0039] 1. Deposition step (see figure 2 )

[0040] like figure 2 As shown, in the deposition step, reactant gas 1 such as SiCl 4 、GeCl 4 , POCl 3 , He and O 2 Inject quartz tube 2. Then, the outside of the quartz tube 2 is heated with the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com