Process for preparing bio-diesel-oil by using microalgae fat

A technology of microalgae oil and biodiesel, which is applied in the direction of preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of preparing biodiesel from heterotrophic microalgae oil, and achieve good application and market demand, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

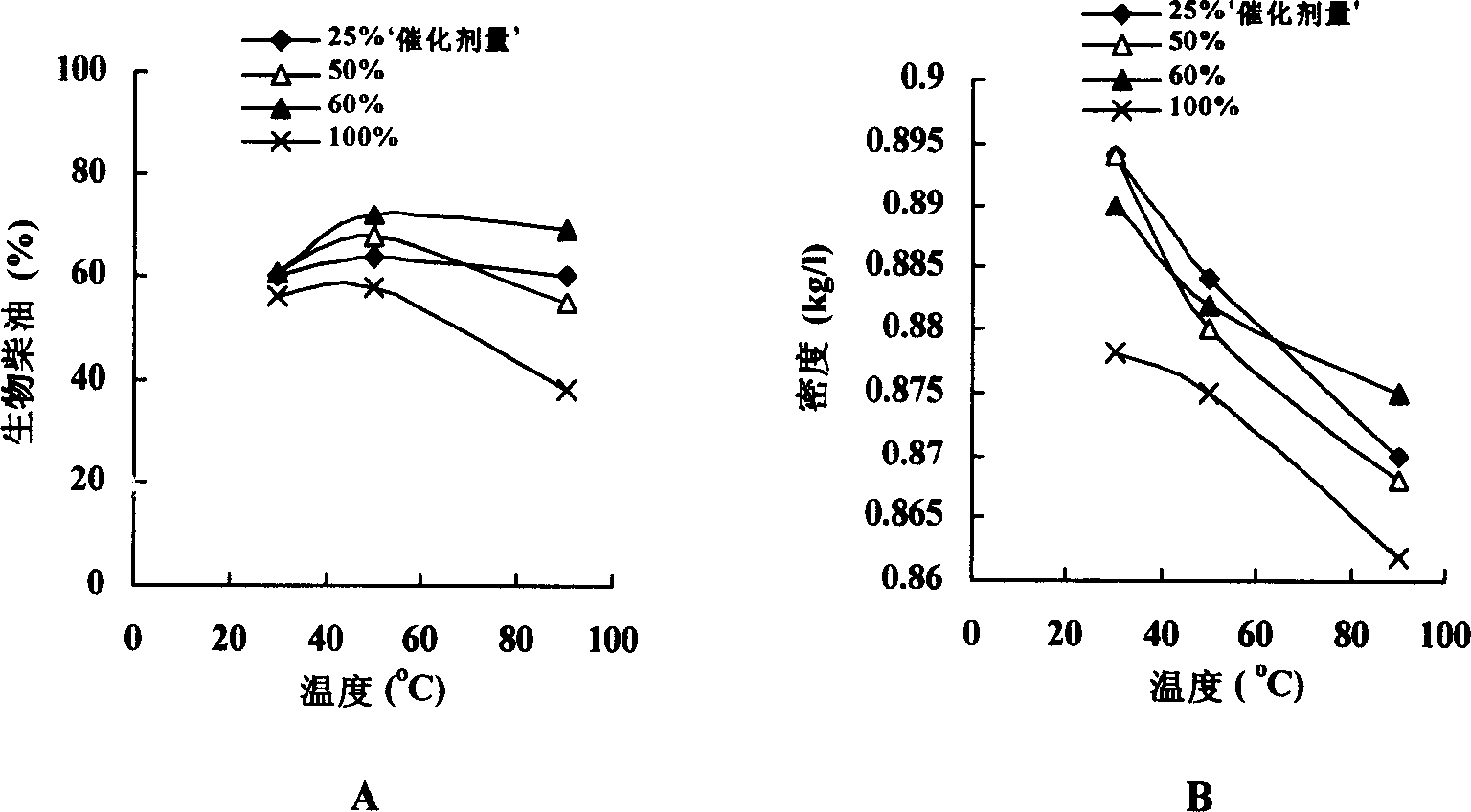

[0018] The influence of embodiment one different reaction temperature and catalyst consumption on microalgae biodiesel yield and density

[0019] The reaction conditions are: 30:1 molar ratio of alcohol to oil, the rotating speed of the shaker is 160 rpm, and the reaction time is 5 hours. The temperature is 30°C, 50°C, 90°C; catalyst H 2 SO 4 Consumption is 25%, 50%, 60%, 100% (based on raw oil weight).

[0020] Higher yield of biodiesel can be obtained at 50℃, while lower density biodiesel can be obtained at 90℃. Under the same temperature conditions, when the amount of catalyst is 100% of the raw oil, biodiesel with lower density can be obtained. The biodiesel with the lowest density (0.862) was obtained at 90°C and the catalyst dosage was 100% of the raw oil.

[0021] Under the condition that the amount of catalyst is 100% of the raw oil, there is no great difference in the yield and density at 30°C and 50°C. The yields of biodiesel at 30°C and 50°C were 56% and 58%, r...

Embodiment 2

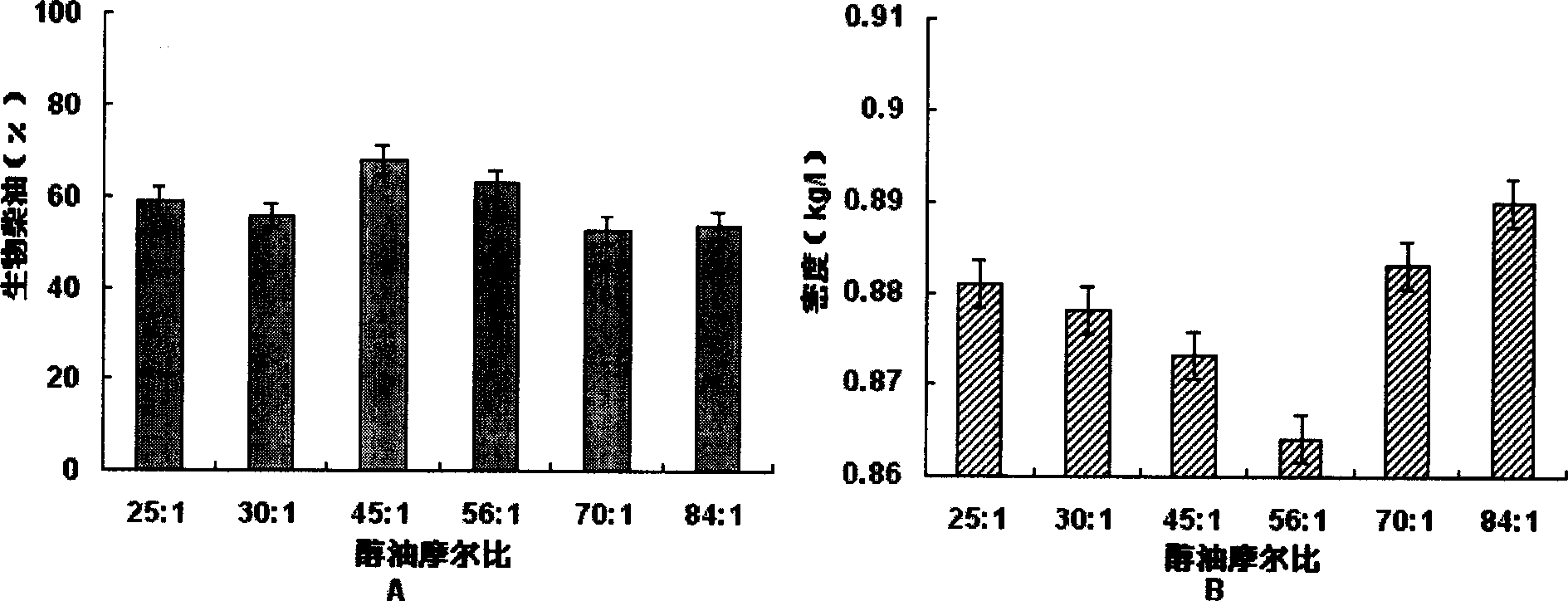

[0022] Example 2 Effects of different alcohol-oil molar ratios on microalgae biodiesel yield and density

[0023] The reaction conditions are: temperature 30°C, shaker speed 160rpm, catalyst H 2 SO 4 The dosage is 100% (based on the weight of raw oil), and the reaction time is 7 hours.

[0024] Comparing the effects of six different molar ratios of alcohol to oil on the product ratio and its density, a higher yield of biodiesel can be obtained when the molar ratio of alcohol to oil is 45:1 and 56:1, which are 68% and 63%, respectively. Under the conditions of these two molar ratios of alcohol to oil, not only a higher yield of biodiesel, but also a low density biodiesel was obtained. The densities of biodiesel obtained when the molar ratio of alcohol to oil was 45:1 and 56:1 were 0.873 and 0.864, respectively. Biodiesel with a lower density (0.878) can also be obtained when the molar ratio of alcohol to oil is 30:1 (such as figure 2 shown).

Embodiment 3

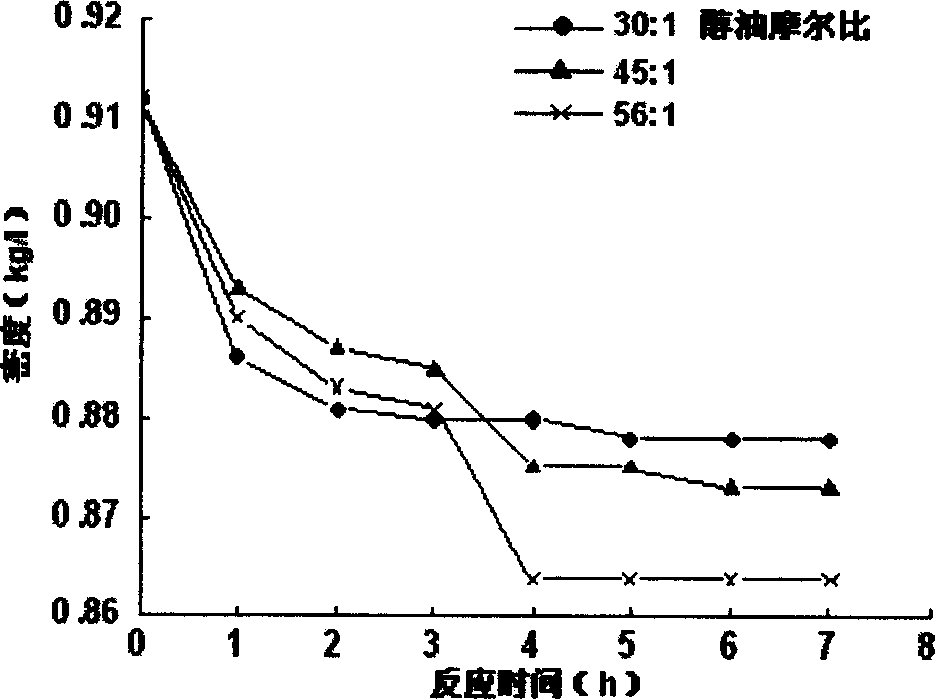

[0025] The variation of the density of the reaction product (biodiesel) over time under the conditions of embodiment three different alcohol-to-oil molar ratios

[0026] The reaction conditions are: temperature 30°C, shaker speed 160rpm, catalyst H 2 SO 4 The dosage is 100% (based on the weight of raw oil)

[0027] The density of biodiesel obtained when the molar ratio of alcohol to oil was 25:1, 70:1 and 84:1 was higher, and the subsequent separation was inconvenient when the amount of methanol was too large. Under the conditions of 30:1, 45:1 and 56:1 molar ratio of alcohol to oil, the densities of biodiesel products gradually decreased with the prolongation of reaction time. However, when the molar ratio of alcohol to oil was 56:1, the density of the biodiesel product dropped to the lowest point in the shortest time of 4 hours, and biodiesel with a density of 0.864 was obtained; while the molar ratio of alcohol to oil was 30:1 and 45:1 , it takes 5-7 hours for its produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com