Fresnel lens sheet, transmission screen and back projection display unit

A Fresnel lens and lens sheet technology, which is applied in the direction of lenses, projectors with built-in screens/external screens, projection devices, etc. The effect of improving contrast, increasing transmittance, and suppressing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] Specific examples of the above-mentioned embodiment will be described below.

[0086] (Example)

[0087] First, using a mold having a complementary shape corresponding to the shape of the prism element and the shape of the groove, a transparent polycarbonate resin (refractive index 1.59) is stamped to form a prism element and The base of the V-shaped groove.

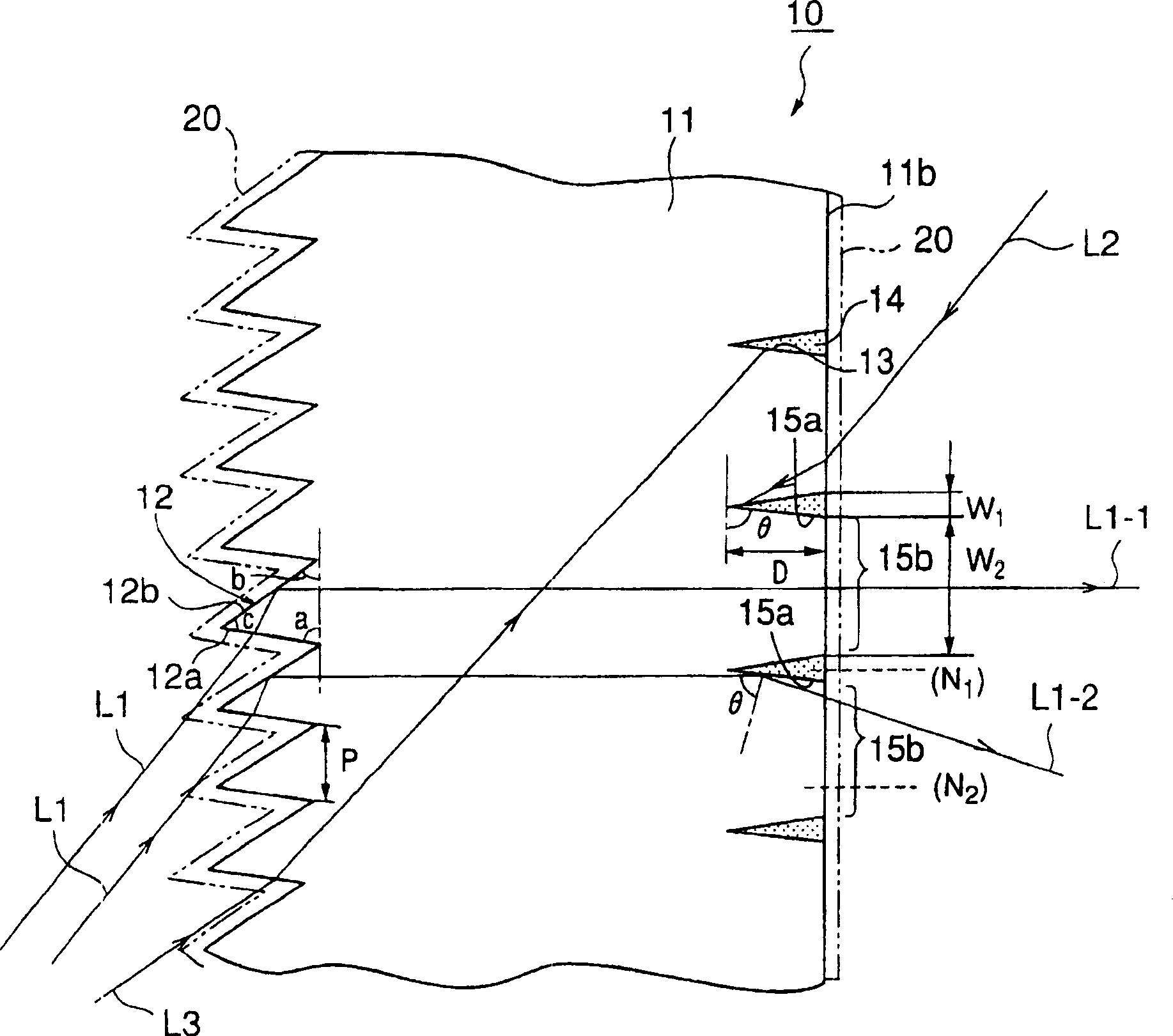

[0088] The base formed here was planar with a width of 1016 mm, a longitudinal length of 762 mm and a thickness of 4 mm. In addition, the prism apex angle (c) of the prism element on the light incident side of the base is fixed at 38 degrees, and the angle (a) of the refraction surface and the angle (b) of the total reflection surface of each prism element are determined according to the incident angle of light (35~ 71 degrees) and change. Also, the lens pitch (p) of the prism element was 0.11 mm. The groove on the light-emitting side of the base corresponds to the shape of the wedge-shaped light-absorbing par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com