Light thermal insulation moveable house and its construction method

A prefabricated house, light-weight technology, applied in the direction of architecture, building structure, etc., can solve the problems of non-reusable, long construction period, large capital occupation, etc., to achieve the overall improvement of rigor, low cost, and comprehensive utilization value improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

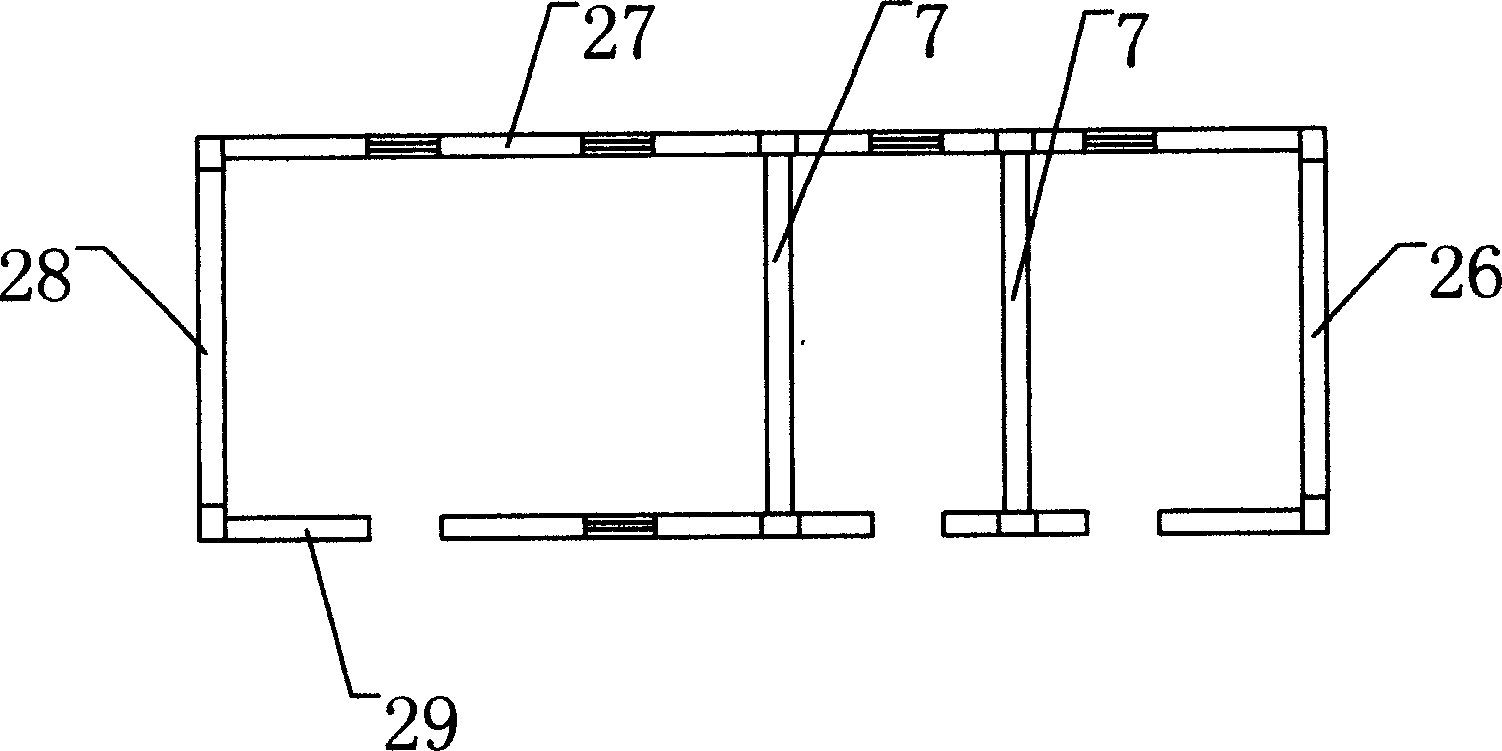

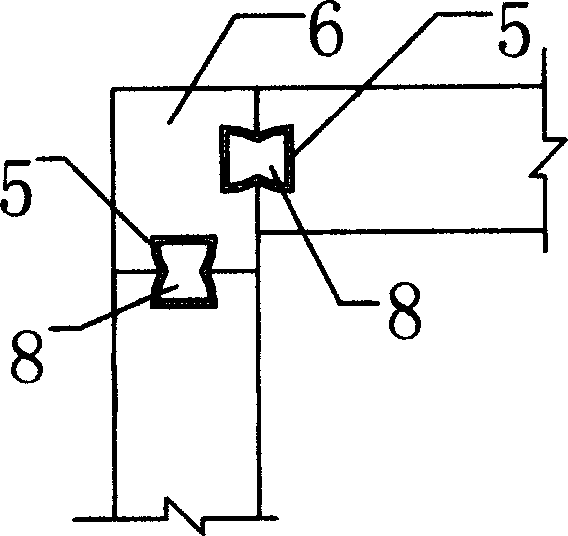

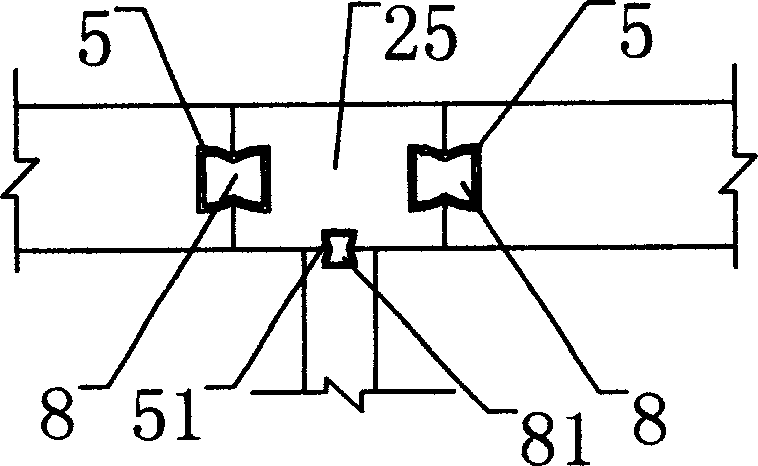

[0032] A light-weight thermal insulation activity room, such as figure 1 As shown, the design is 3 meters in bay, 5 meters in depth, and 2.8 meters in net height. Such as Image 6 As shown, the connection between the floor panel 1 and the wall panel 2 is provided with a connection block 3, and the lower part of the wall panel 2 is provided with a connection groove 4 corresponding to the connection block 3, and the connection between the floor panel 1 and the wall panel 2 Connection block 3 is square, such as figure 2 As shown, vertical connecting grooves 5 are provided on both sides of the wall panel, and concrete columns 6 are provided between the wall panels at the corners of the wall, and the connecting piece 8 between the wall panel and the concrete columns 6 is dovetail-shaped. Between the wall panel and the concrete column 6, there is a connecting piece 8 corresponding to the connecting groove 5, such as Image 6 As shown, the connection between the roof panel 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com