Steam pressurizing pipe pile making process

A manufacturing method and a technology for pipe piles, which are applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve the effects of high density, improved product quality, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

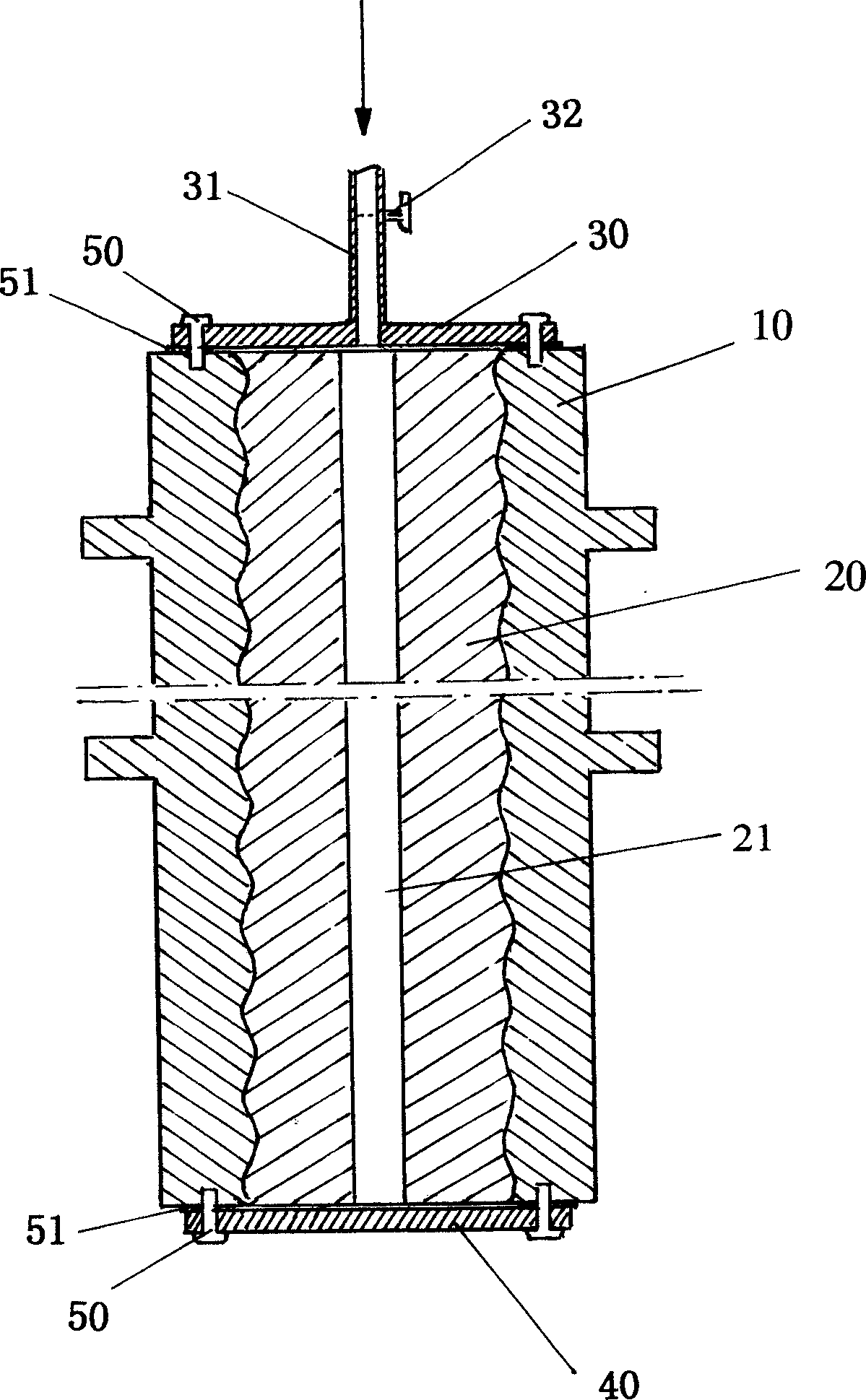

[0014] Such as figure 1 As shown, it is a schematic diagram of the structure of the pipe pile equipped with steam pipes according to the present invention. The steam pressurization manufacturing method of the pipe pile includes high-pressure steam treatment after the pipe pile 20 is centrifugally shaped, wherein, after the pipe pile 20 is centrifugally shaped, Install sealing steel plates 30, 40 at both ends of the two semicircular steel molds 10, and fix them with sealing washers 51 or fastening bolts 50, and the center of the sealing steel plate 30 at one end is equipped with a through hole 21 aligned with the center of the pipe pile 20 The steam pipe 31 is equipped with a steam valve 32 on the steam pipe 31. When the steam pipe 31 is connected with the high-pressure steam pipe (not shown in the figure), the steam valve 32 is opened and the high-pressure steam is connected to the pipe pile 20. Carry out heat treatment, after heat treatment, close steam vent valve 32, take of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com