Hinged tractor with hydraulic driver on back wheel

A driving device and tractor technology, which is applied in the field of tractors, can solve problems such as poor climbing ability and easy skidding, and achieve the effects of good maneuverability, enhanced climbing ability, and increased load capacity and driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

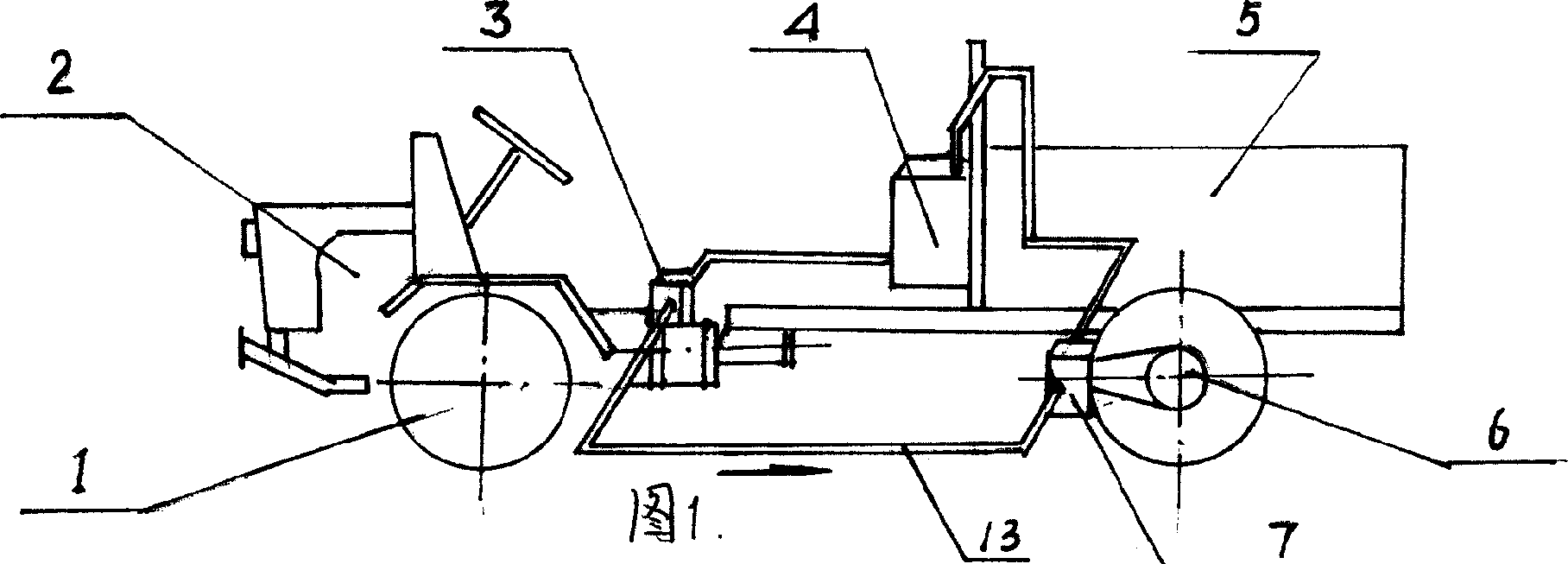

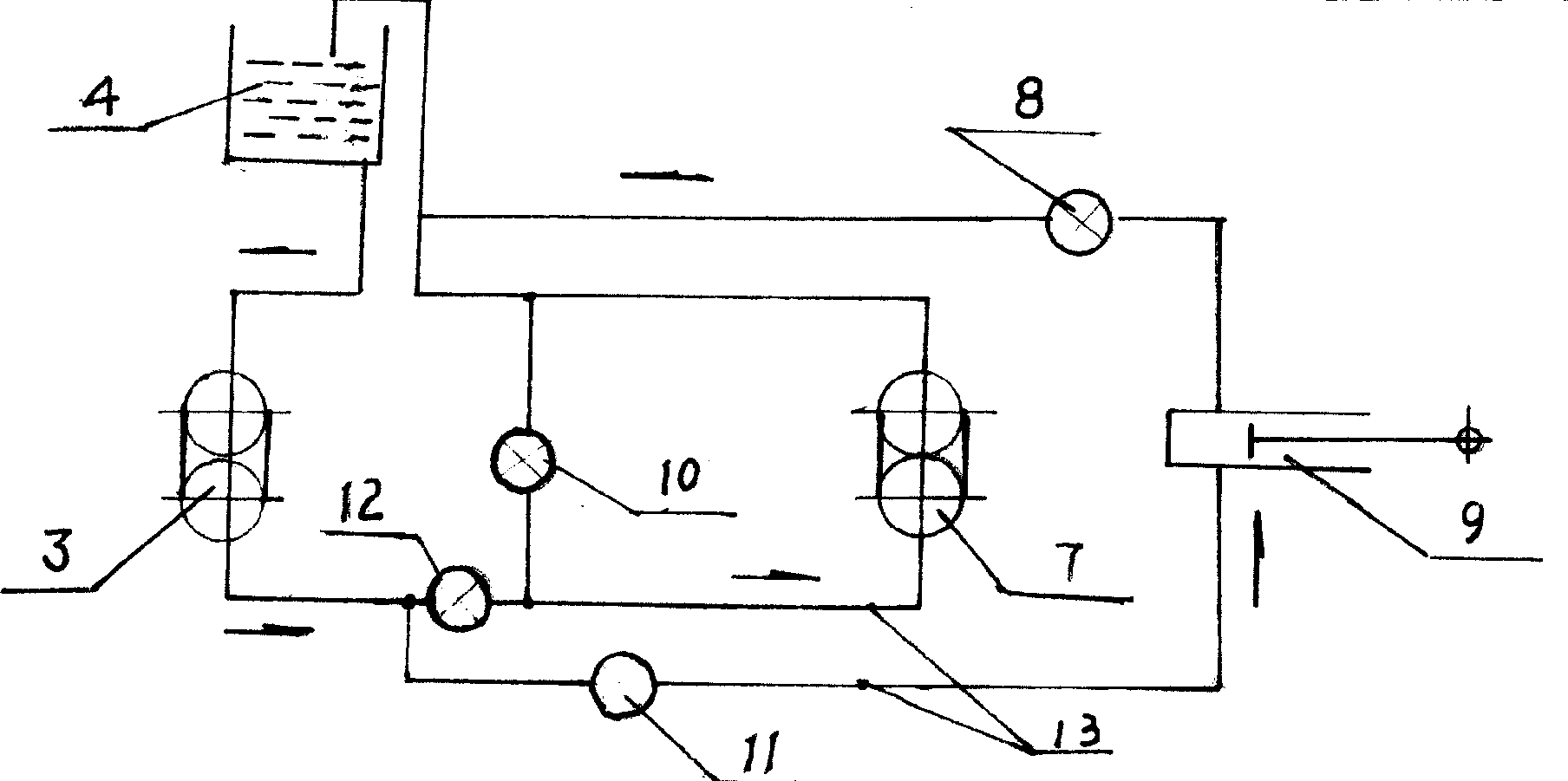

[0010] Referring to the attached picture:

[0011] Including tractor front wheel (1), machine head (2), trailer (5), trailer rear wheel (6), gear pump (3), hydraulic oil cylinder (9), hydraulic oil tank (4), valve-1 (11) and valve-2(8) on the existing articulated 12Y tractor of the hydraulic lifting device that forms and the connecting device of headstock and trailer, set up one by oil motor (7) one-way valve (10), valve-3 (12) and the hydraulic drive unit that pipeline (13) forms, and wherein oil motor (7) can be converted into by the gear pump of 320 type or 316 type, 314 type, 310 type, is installed on the trailer rear axle, oil motor two One end is connected with a check valve (10) in parallel through a pipeline, and after connecting a manual three-way valve-3 (12) in series through a pipeline (13) at one end of the oil motor and the check valve connected in parallel, on the one hand, through the pipeline and the original valve -1 (11), valve-2 (8) are connected in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com