Multifunctional machine clip turning tool

A multi-function machine and turning tool technology, which is applied to tools for lathes, turning equipment, accessories of tool holders, etc., can solve the problem that indexable inserts cannot be reground, and achieve the effect of simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiment that accompanying drawing provides:

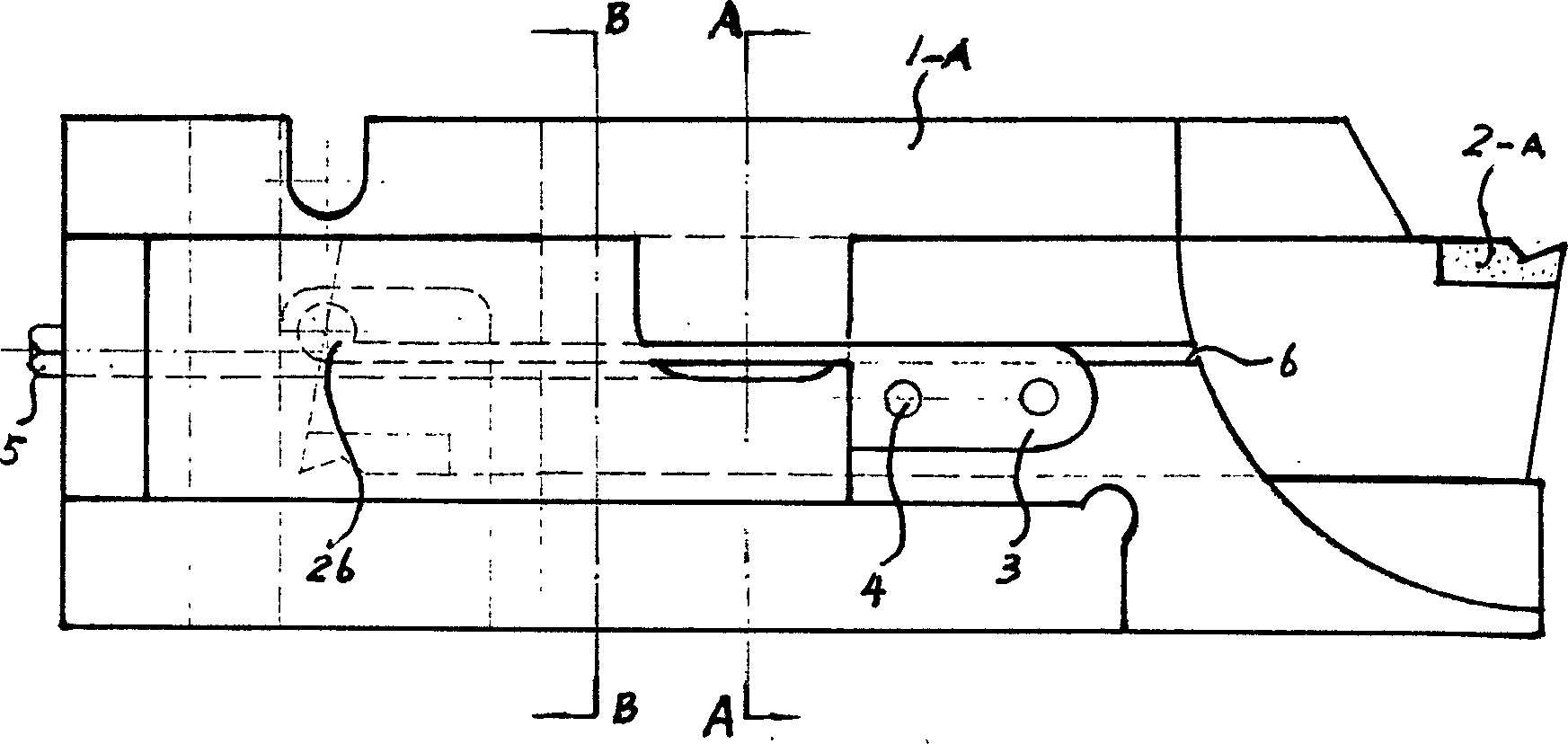

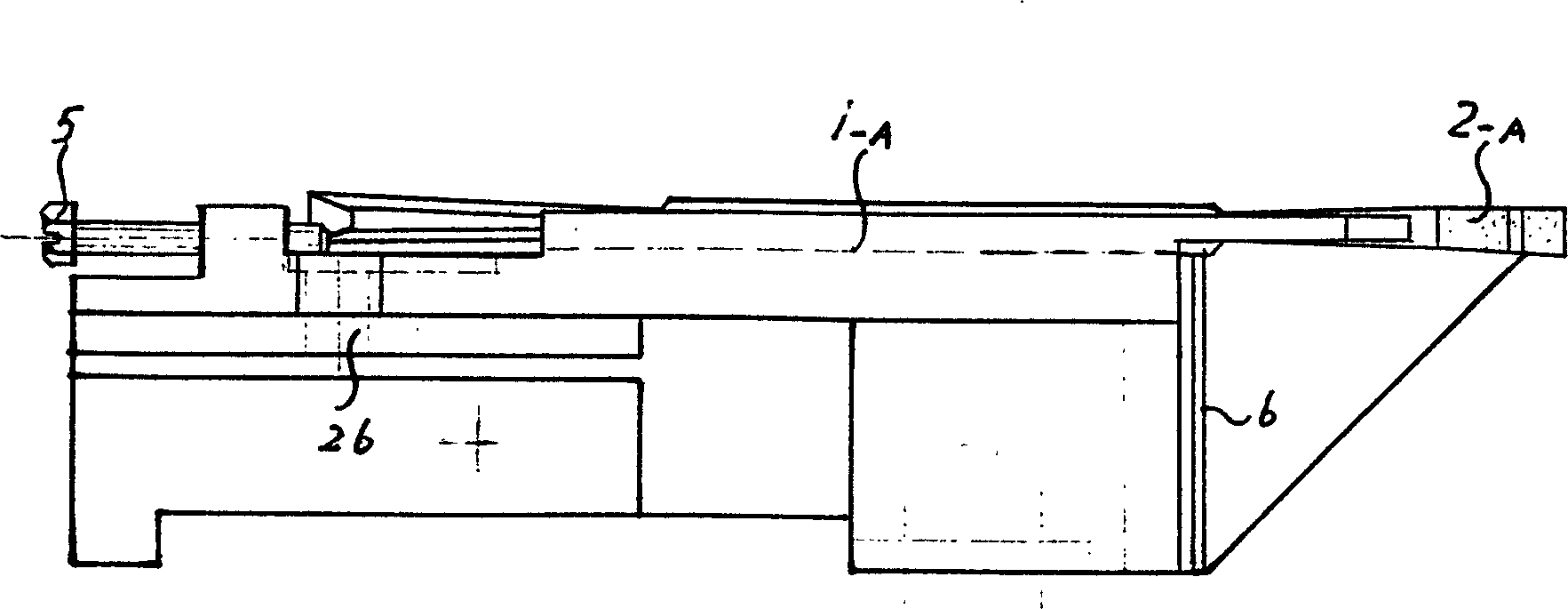

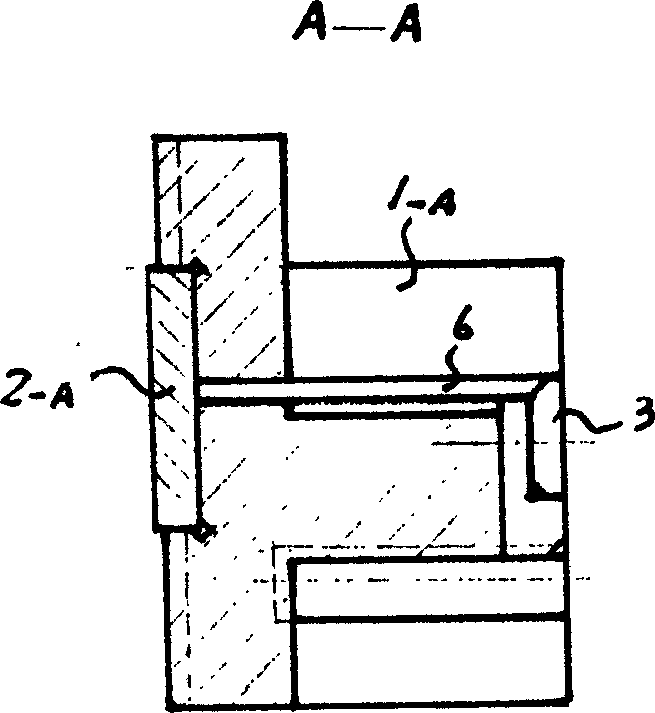

[0028] Figure 1 to Figure 4Among them, the cutter body 1-A, the blade 2-A, the balance weight 3, the balance weight fixing pin 4, and the adjustment screw 5 are composed of a positionable clamp cutter, which is a tool suitable for cutting workpieces. Blade 2-A is the elongated blade that all has blade at two ends, and its two ends blades are reversed namely blade use end upward spare end downward. 26 is an elastic hole. The upper end of the balance weight 3 is in line with the upper plane of the elastic slot 6 .

[0029] Figure 5 to Figure 8 Among them, there is a Shaped groove, the longitudinal edge of the groove extends to the cutter body afterbody, and its longitudinal groove forms two side planes 15,16 and a bottom surface 14; The groove divides the upper plane 13 of the cutter body 1-A into three sections (13- 1, 13-2, 13-3), the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com