Remote-monitoring power free automatic compensating controller

A technology of remote monitoring and automatic compensation, applied in the direction of reactive power adjustment/elimination/compensation, reactive power compensation, etc., can solve the problems of inability to achieve reactive power compensation, low intelligence, short capacitor life, etc., to achieve easy standardization and Standardized management, high level of intelligence, and good capacity scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

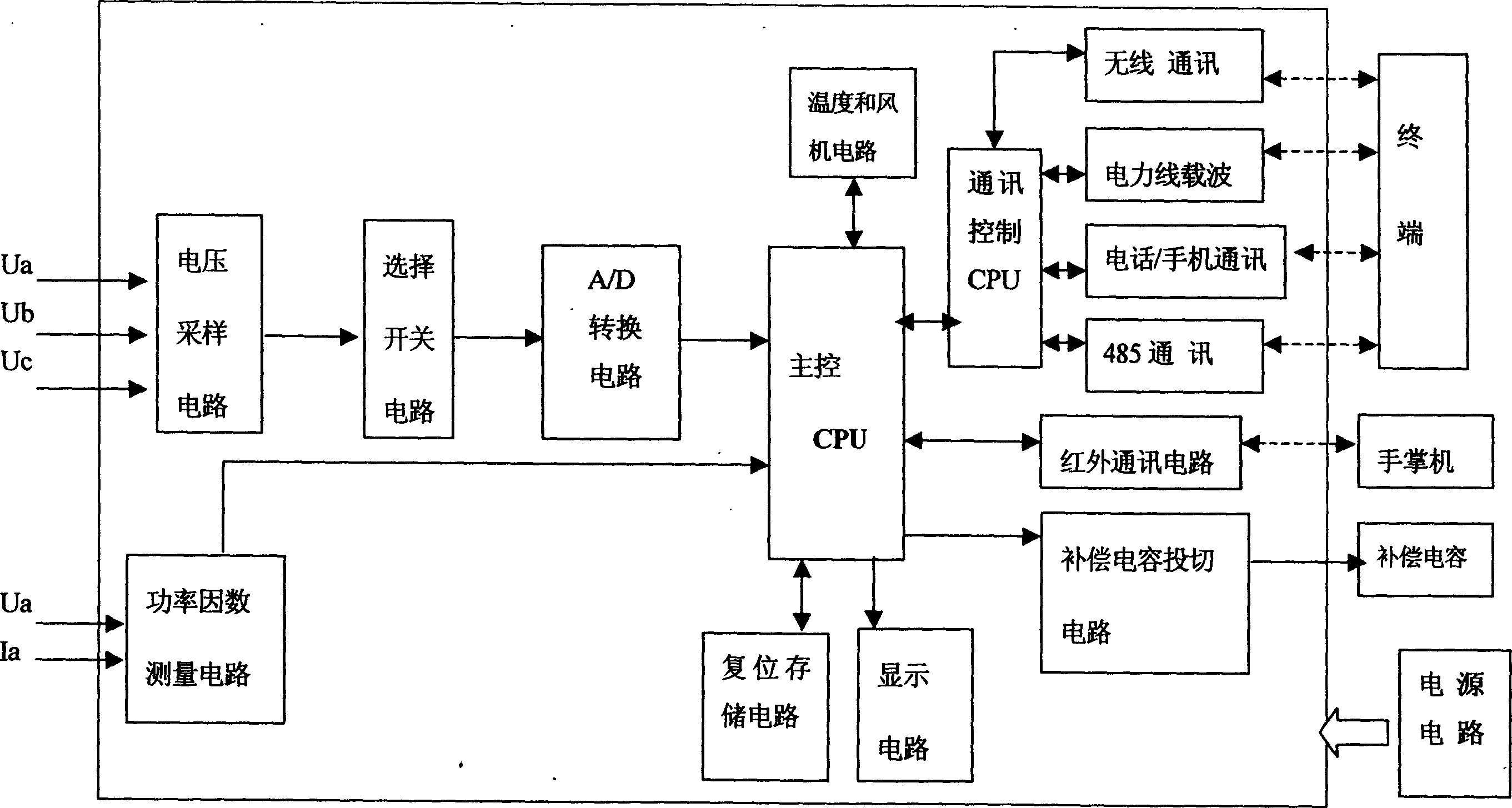

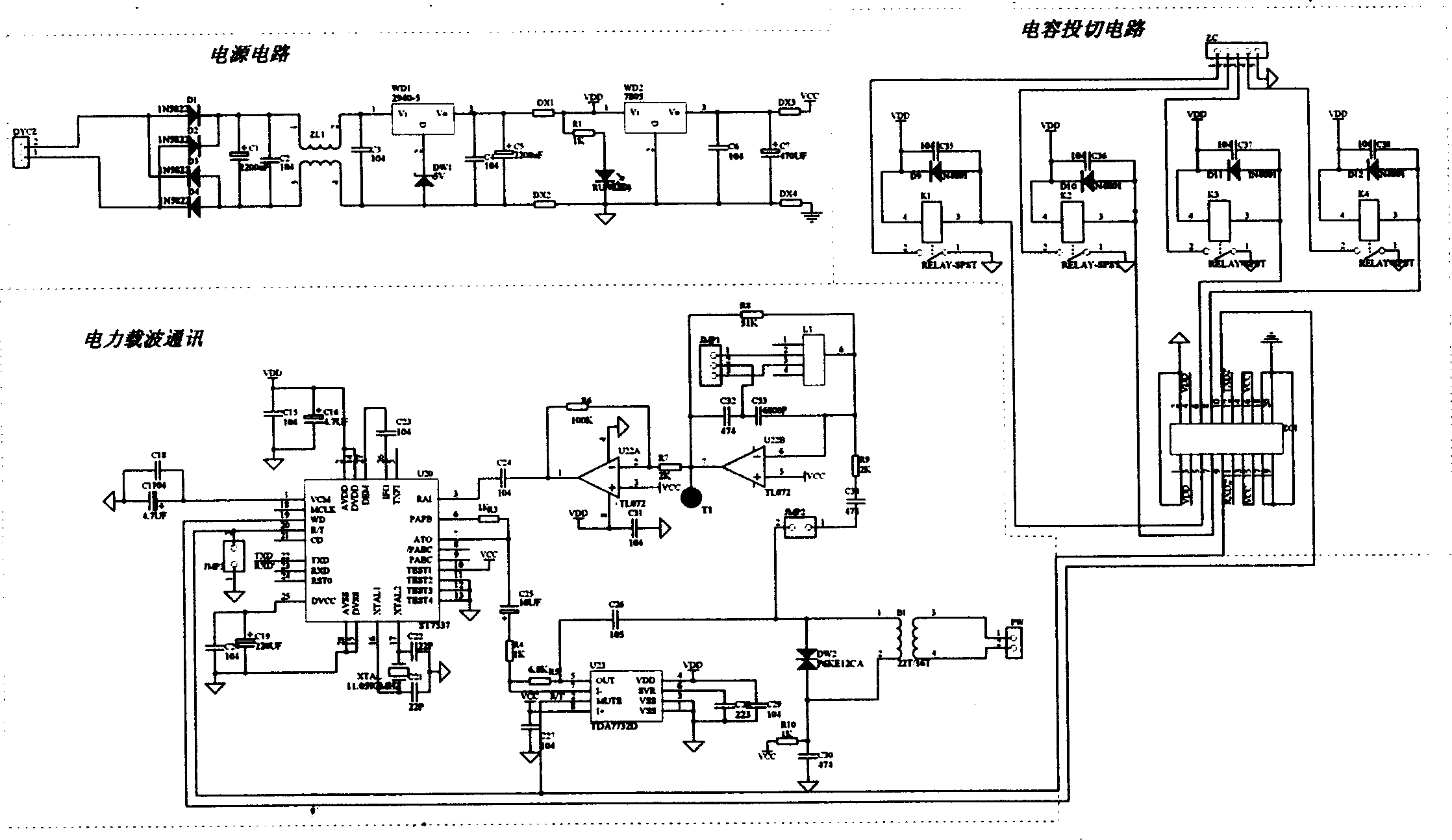

[0012] exist figure 1 Among them, the present invention includes a power supply circuit, a voltage sampling circuit, a selection switch circuit, an A / D conversion circuit and a main control CPU connected in sequence, and a reset storage circuit and a display circuit are connected to the main control CPU, and the main control CPU They are respectively connected with the power factor measurement circuit, the compensation capacitor switching circuit, the infrared communication circuit and the communication control CPU, and the communication control CPU is connected with the signal transceiver.

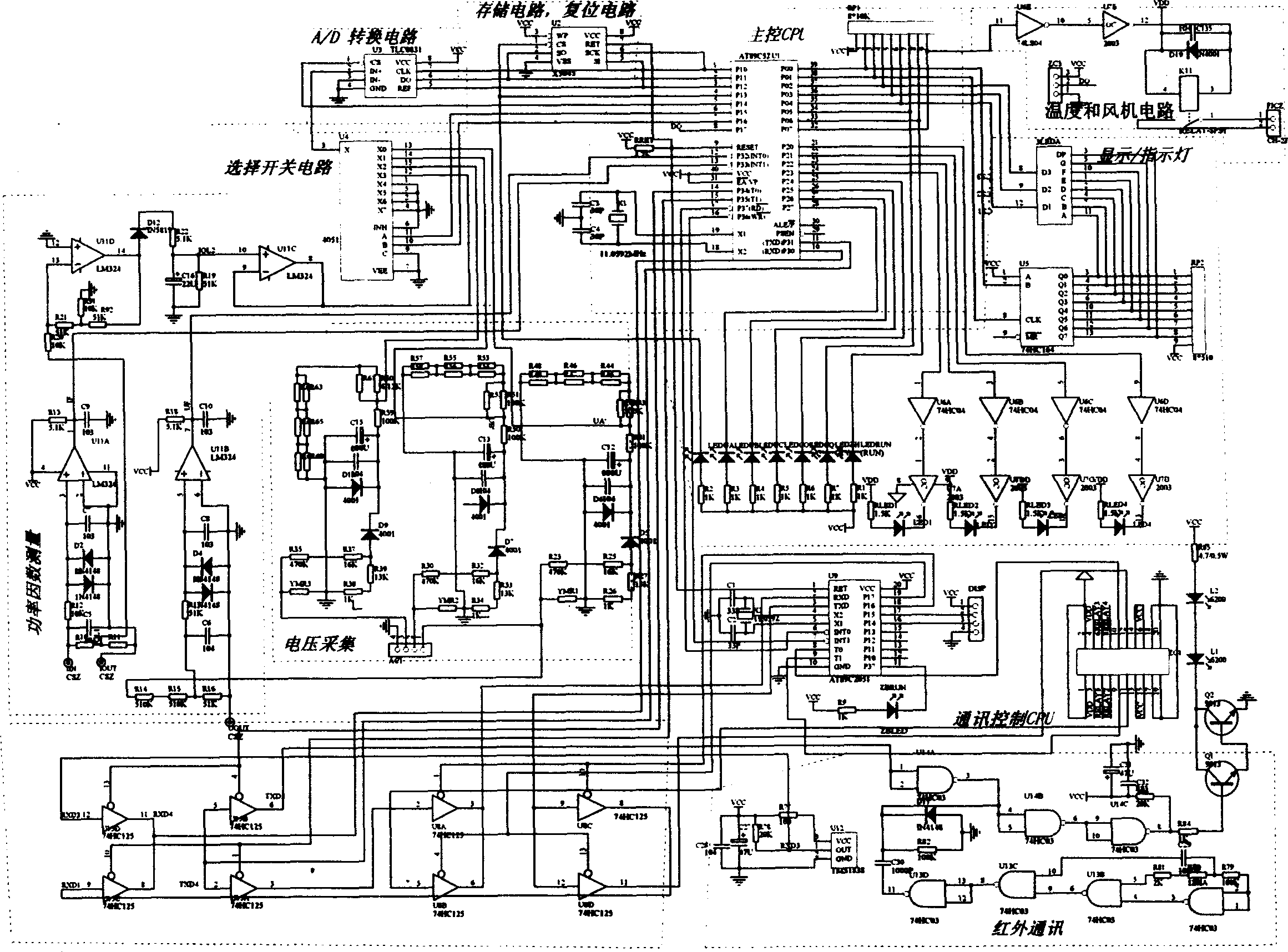

[0013] exist figure 2 , in, the main control CPU of the present invention is made of integrated circuit U1 and its peripheral circuit, and the model that integrated circuit U1 selects is AT89C52, and its pin 6, pin 7 are connected with selection switch circuit, and selection switch circuit is made of integrated circuit U4 , the model is 4051; the pin 1, pin 2, pin 3, and pin 4 of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com