Long life rotating body with excellent fatigue strength and method of manufacturing the rotating body

A technology of fatigue strength and rotating body, applied in the field of long-life rotating body and its manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

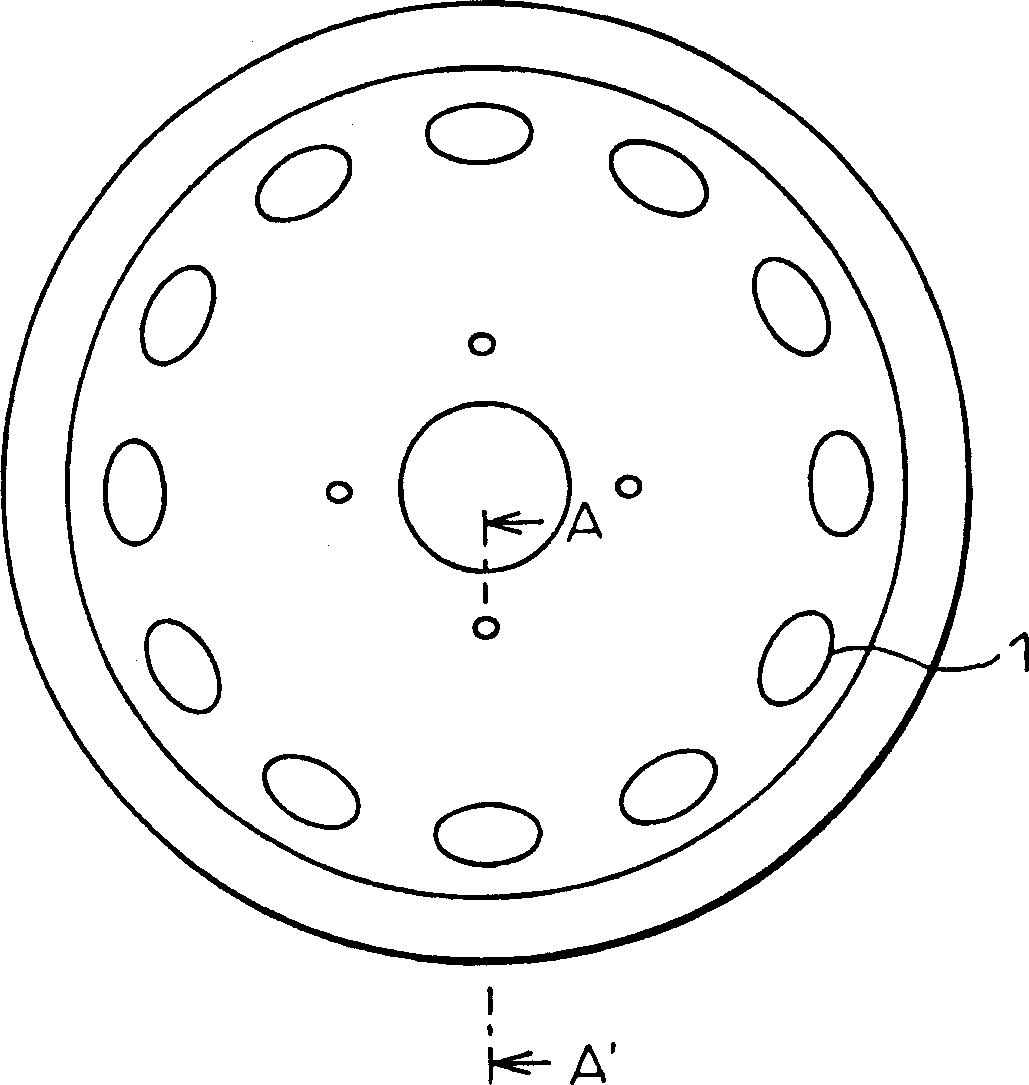

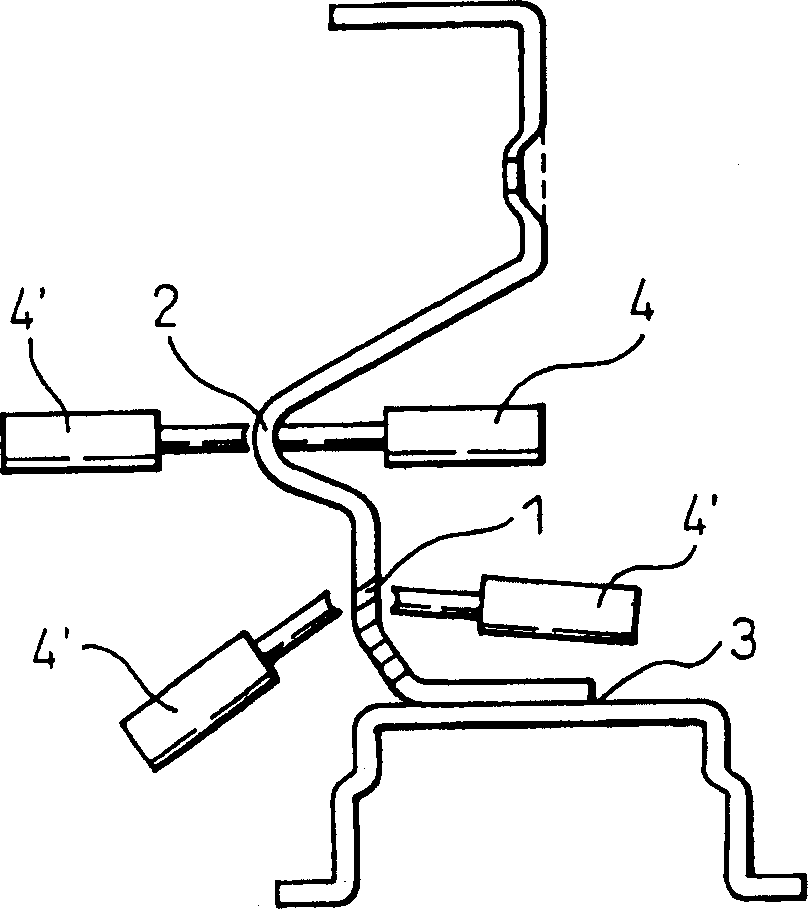

[0049] The effects of the present invention will be described with reference to an example of an automobile wheel made of steel plate in the present invention.

[0050] For 13-inch wheels of automobiles, the treatment method was changed to compare the fatigue strength. In addition, the wheel disc used here is made of a plate with a thickness of 3.2mm and a strength of 690N / mm 2 And plate thickness 4.0mm, strength 330N / mm 2 processed from materials.

[0051] The fatigue test is carried out with a rotating bending moment (bending moment) load. The alternating speed is 700rpm, the bolt tightening torque is 98Nm, and the test torque is 1.47KNm.

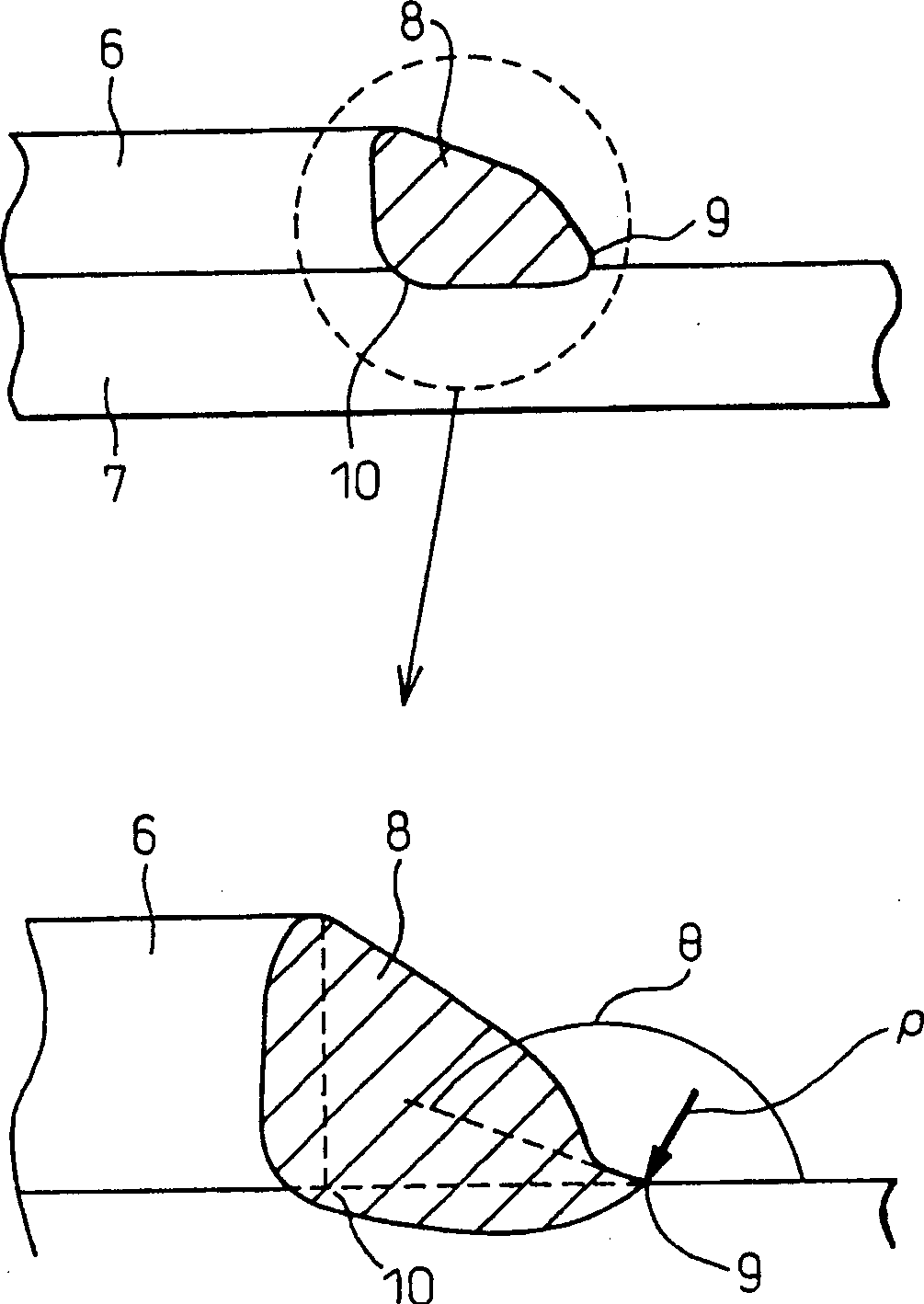

[0052] In addition, as the initial crack before the treatment, a notch with a depth of 200 μm was artificially made at the end of the punched hole, and the corresponding part was cut out after the test, and the crack length was measured. The results are shown in Table 1.

[0053] No.

differentiate

steel

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com