Ultrasonic motor

An ultrasonic motor, ultrasonic technology, applied in the directions of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the limitation of the layout position, difficult to ensure the holding torque, difficult to improve the stop position Resolution and other issues, to achieve the effect of less layout space and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described below with reference to the drawings.

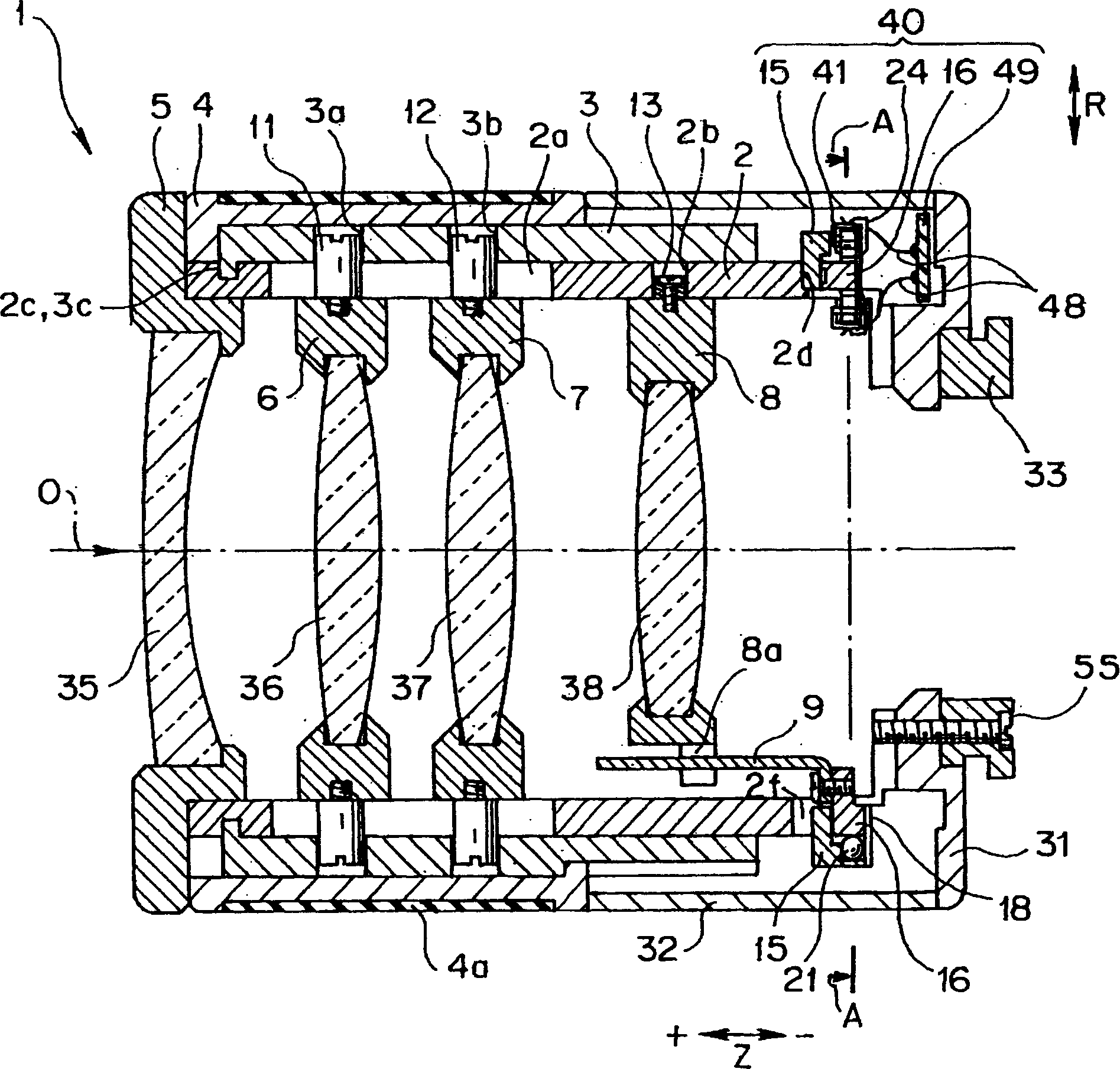

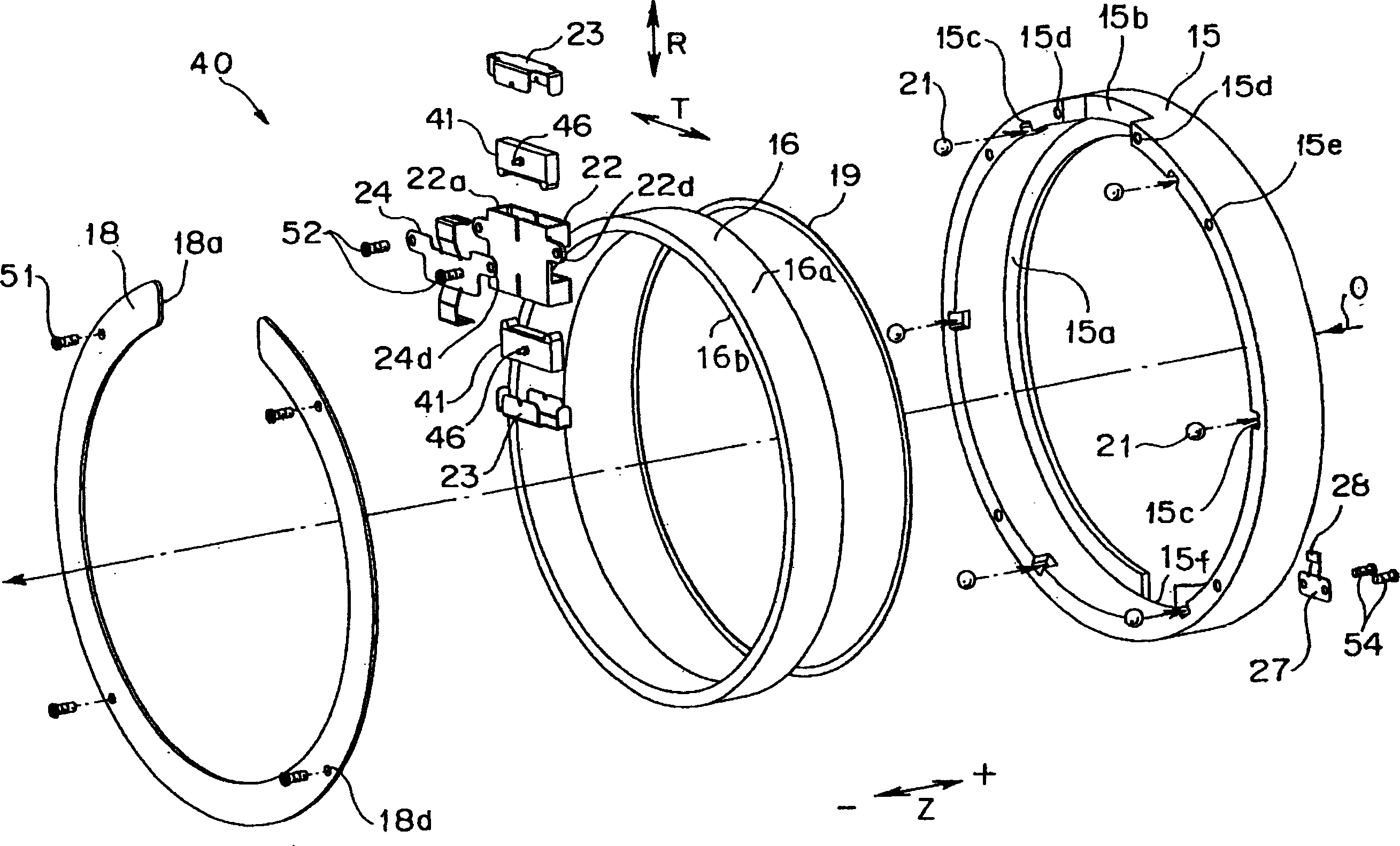

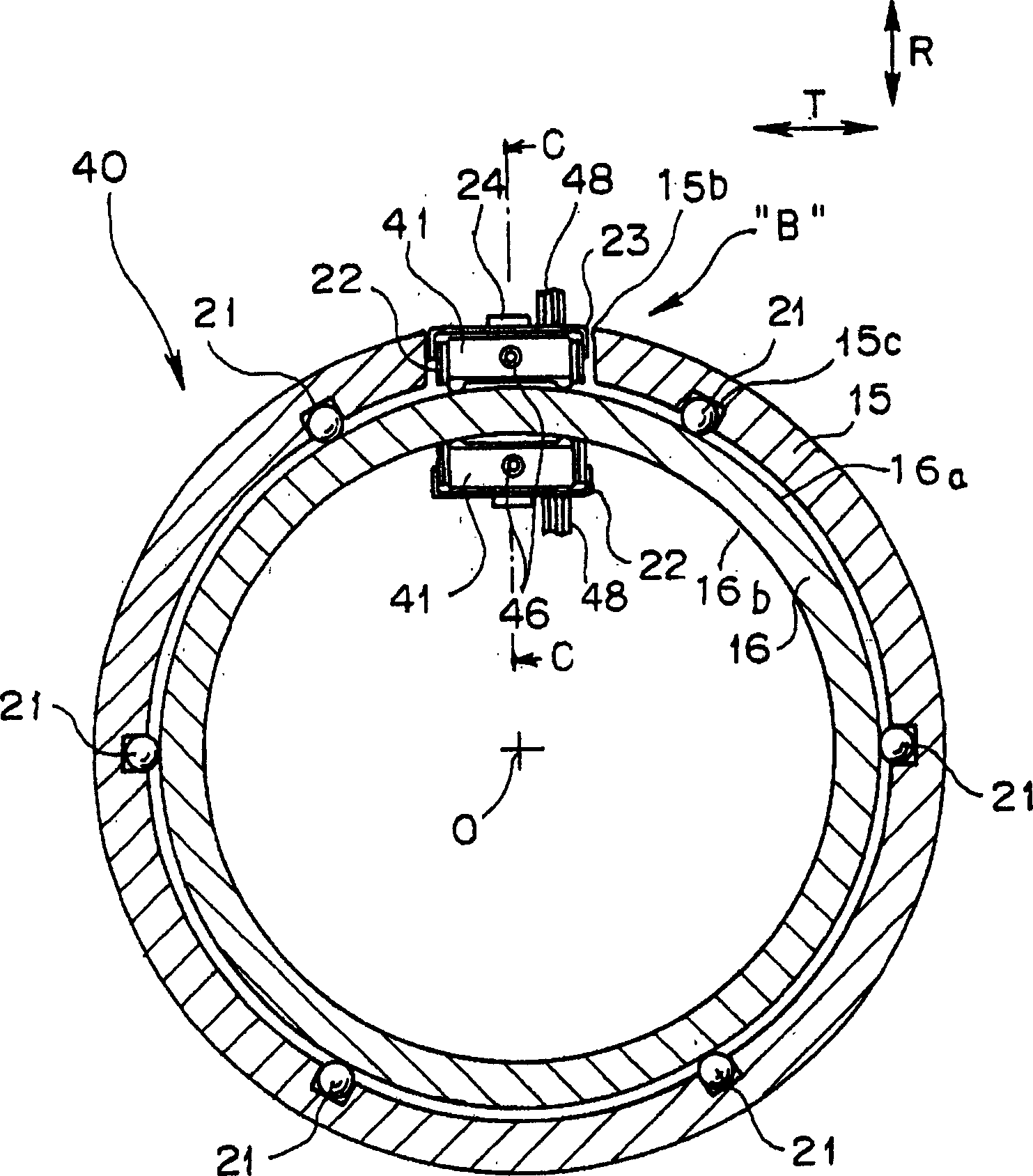

[0040] figure 1 It is a vertical sectional view of the optical axis of the lens barrel including the ultrasonic motor according to the first embodiment of the present invention; figure 2 It is an exploded perspective view of the above-mentioned ultrasonic motor, but it is a perspective view seen from the imaging side in the direction of the optical axis; image 3 is alongfigure 1 The cross-sectional view of line A-A in ; Figure 4 yes image 3 The enlarged view of part B of , showing the installation state of the vibrator of the above-mentioned ultrasonic motor part; Figure 5 It is a perspective view of a vibrator assembly in a state where the above-mentioned vibrator is assembled in a vibrator holder; Image 6 is an exploded perspective view of the vibrator assembly; Figure 7 yes image 3 The enlarged cross-sectional view of part C-C in , showing the installation sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com