Shock-proof energy conversion controller

A control device and energy conversion device technology, applied in the direction of machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc., can solve problems such as failure of energy-consuming components, large energy required for active control, and unsuitable reliability guarantees, etc., to achieve Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

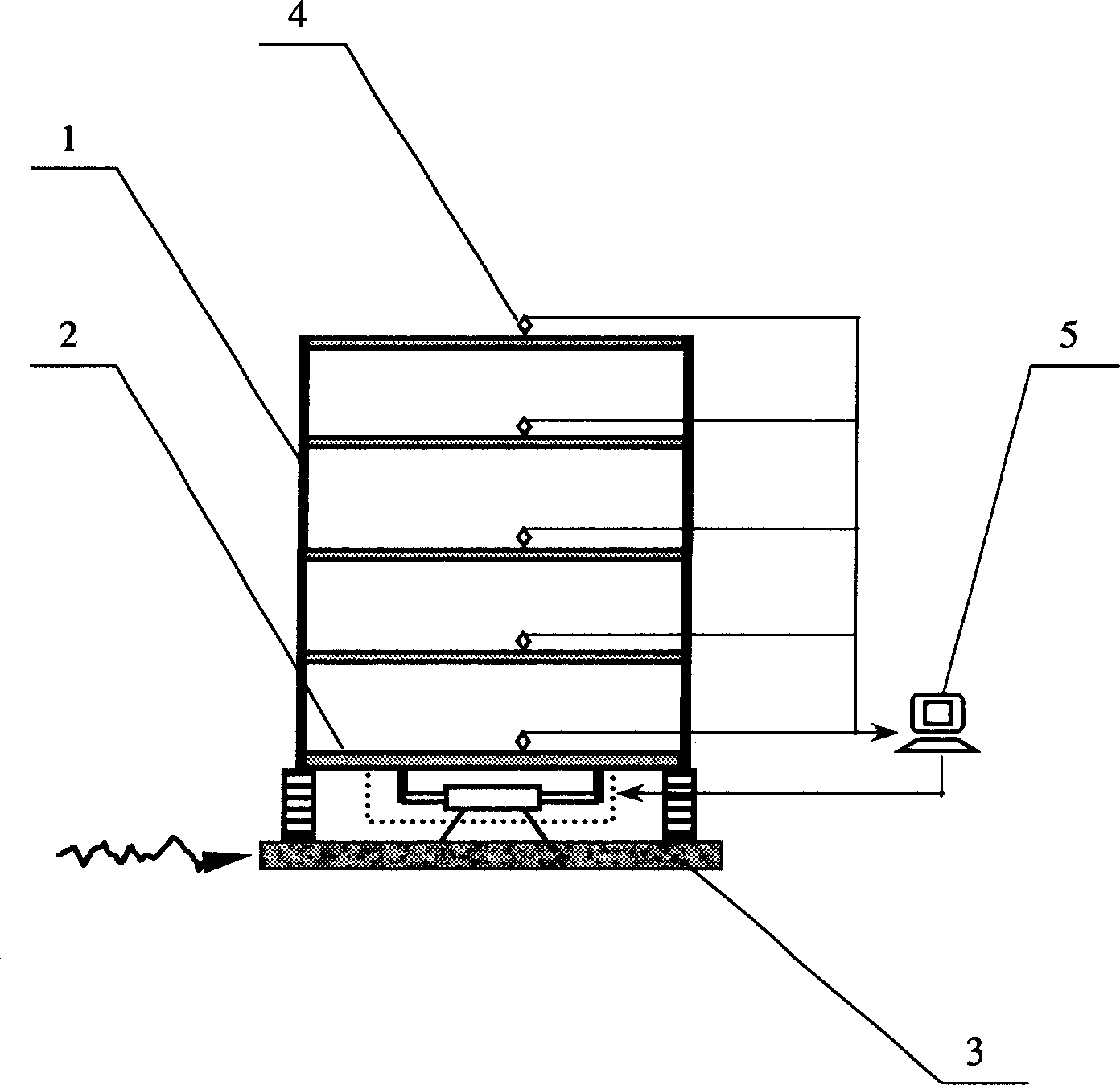

[0020] The vibration isolation energy conversion control device of the present invention is as figure 1 As shown, the bottom of the building structure 1 is composed of the upper base plate 2 of the seismic isolation layer, the lower base plate 3 of the seismic isolation layer, the airbag hydraulic accumulator 6, the overflow valve 7, the three-position four-way electromagnetic reversing valve 8, the hydraulic pressure Oil cylinder 9, hydraulic cylinder piston 10, one-way valve 12-15, and hydraulic tank 16-19 are composed.

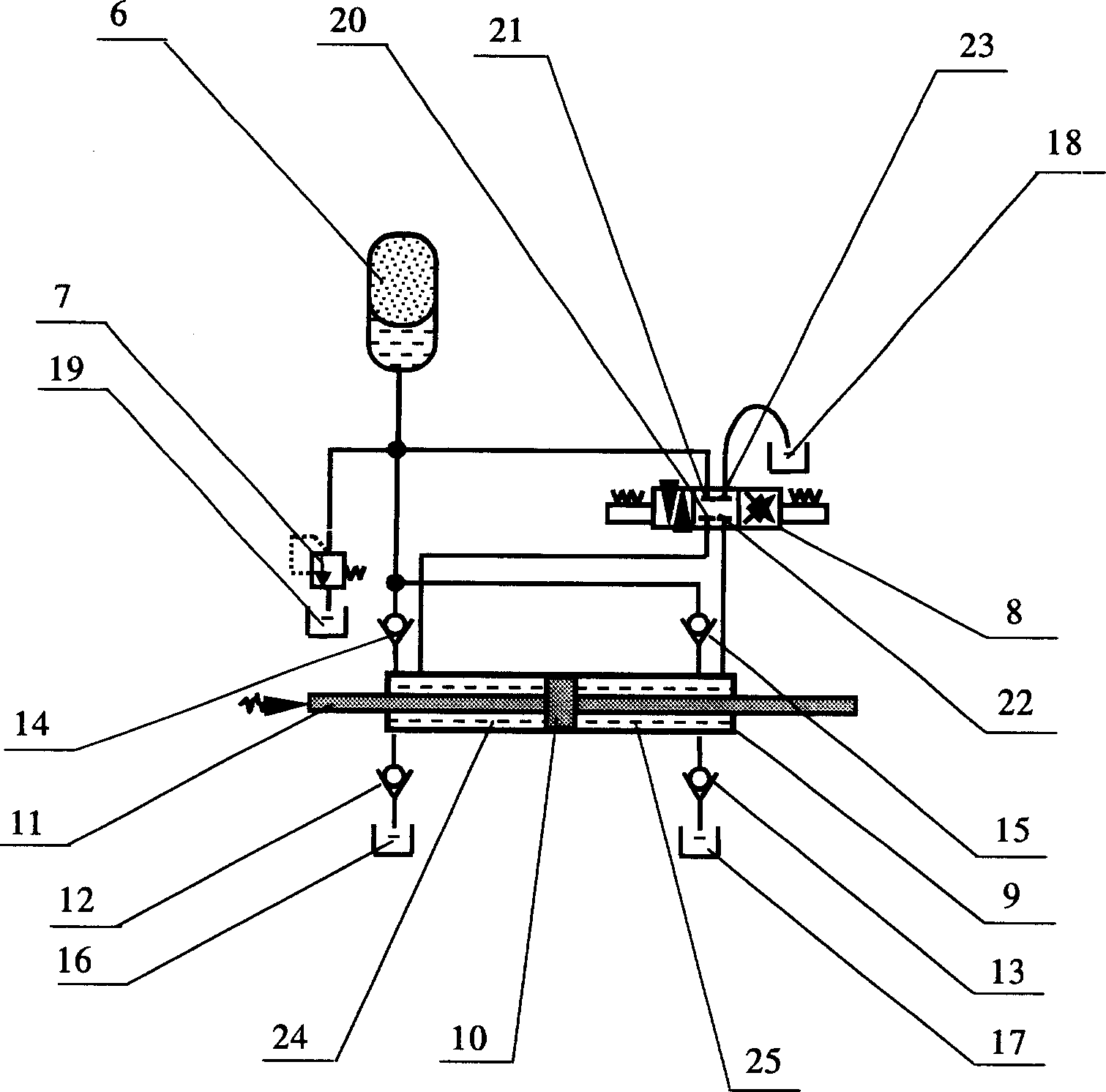

[0021] The internal structure of the transducer is as figure 2 As shown, the hydraulic cylinder 9 is divided into A cylinder 24 and B cylinder 25 by the piston. The A cylinder 24 is connected with check valves 12 and 14. The check valve 12 is connected with the hydraulic tank 16. Device 6 is connected; B cylinder 25 is connected with check valve 13,15, and check valve 13 is connected with hydraulic tank 17, and check valve 15 is connected with air bag typ...

Embodiment 2

[0023] Working status of vibration isolation and energy conversion:

[0024] Such as figure 2 As shown, when the three-position four-way electromagnetic reversing valve 8 is in the middle cut-off position, the oil circuit connected with the three-position four-way electromagnetic reversing valve 8 does not flow. When the structural vibration drives the piston 10 of the hydraulic cylinder 9 to move to the right relative to the hydraulic cylinder 9, the volume of the chamber A 24 increases and the pressure decreases, so that the one-way valve 12 is opened, the one-way valve 14 is closed, and the hydraulic oil is drawn from the hydraulic tank 16 At the same time, the volume of B chamber decreases, the pressure increases, the one-way valve 15 opens, the one-way valve 13 closes, and the hydraulic oil is pressed into the air bag hydraulic accumulator 6 from B chamber 25 , thus realizing the conversion of kinetic energy of structural vibration into hydraulic energy. The flow direc...

Embodiment 3

[0026] Actively control working status:

[0027] According to the needs of structural response information and vibration control, the energy conversion control device can also play a control role, that is, use the high-pressure oil stored in the accumulator 6 as an energy source, and control it by the hydraulic cylinder through the control of the three-way four-position electromagnetic reversing valve 8 9 Apply forces to the structure. The structural response information is transmitted to the computer 5 through the structural response information sensor 4, and the computer 5 controls the operation of the three-way four-position electromagnetic reversing valve 8.

[0028] When the piston 10 of the hydraulic cylinder 9 needs to apply a force to the right, the three-way four-position electromagnetic reversing valve 8 can connect the airbag hydraulic accumulator 6 with the A chamber 24. At this time, the oil pressure of the A chamber 24 is very high. At the same time, the chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com