Eddy magnetic damping type damper

A technology of buffer damping and magnetic damping, which is applied in the direction of magnetic springs, springs, springs/shock absorbers, etc., and can solve problems such as easy leakage, high manufacturing precision of damping elements, and narrow operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

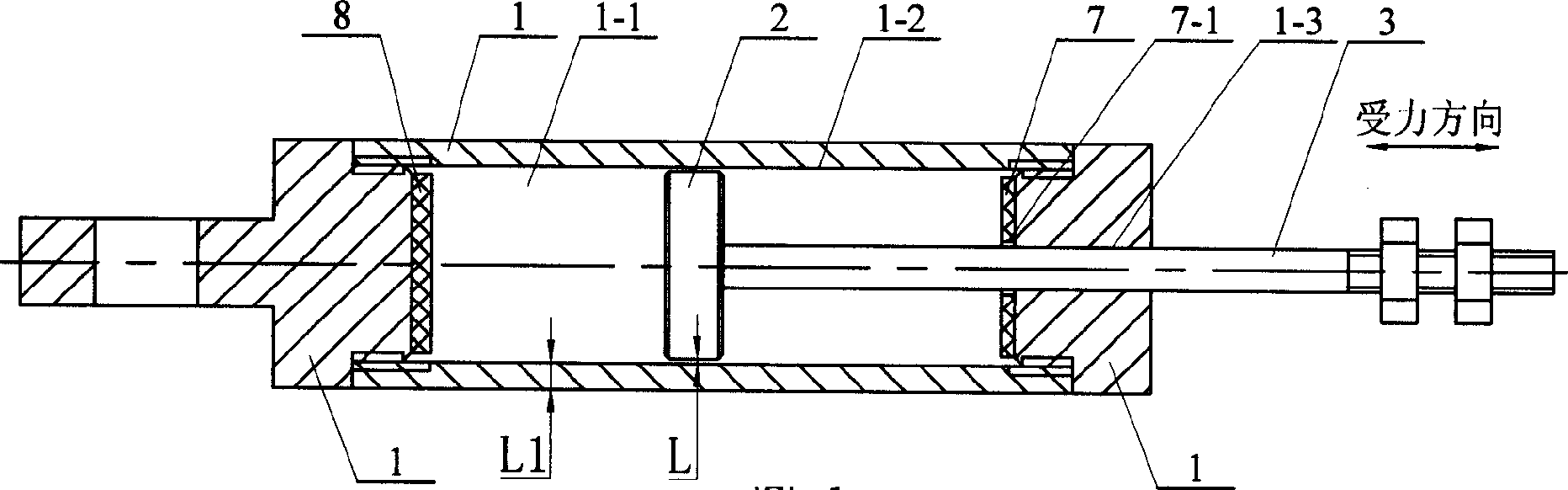

[0005] Specific implementation mode one: combine figure 1 Describe this embodiment, it is made up of metal shell 1, circular permanent magnet 2, guide rod 3; Metal shell 1 inside has cylindrical cavity 1-1; The outer circle surface of circular permanent magnet 2 and metal shell The circular cavity wall 1-2 of the inner cylindrical cavity 1-1 of the body 1 is slidingly connected, the left end surface of the guide rod 3 is connected with the right magnetic pole surface of the circular permanent magnet 2, and the right end of the guide rod 3 passes through the metal A section is exposed behind the through hole 1-3 on the right end of the housing 1, and the circular permanent magnet 2 is axially magnetized. The material of the circular permanent magnet 2 can be selected from NdFeB, SmCo, AlNiCo.

specific Embodiment approach 2

[0006] Specific implementation mode two: combination figure 1 To illustrate this embodiment, there is a gap L between the outer circular surface of the circular permanent magnet 2 and the circular cavity wall 1-2 of the cylindrical cavity 1-1 inside the metal shell 1 in the specific embodiment one. The gap L is 0.01 mm to 0.8 mm; the wall thickness L1 of the metal shell 1 is 1 mm to 6 mm; the surface roughness of the circular cavity wall 1-2 of the cylindrical cavity 1-1 inside the metal shell 1 is less than or equal to 1.6 μm .

specific Embodiment approach 3

[0007] Specific implementation mode three: combination figure 1 To describe this embodiment, in the first embodiment, the material of the metal shell 1 is copper, copper alloy or aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com