Vibration reduction structure of low-temperature scanning near-field optical microscope

A technology of scanning near-field optics and vibration-damping structures, applied in scanning probe microscopy, scanning probe technology, non-rotational vibration suppression, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

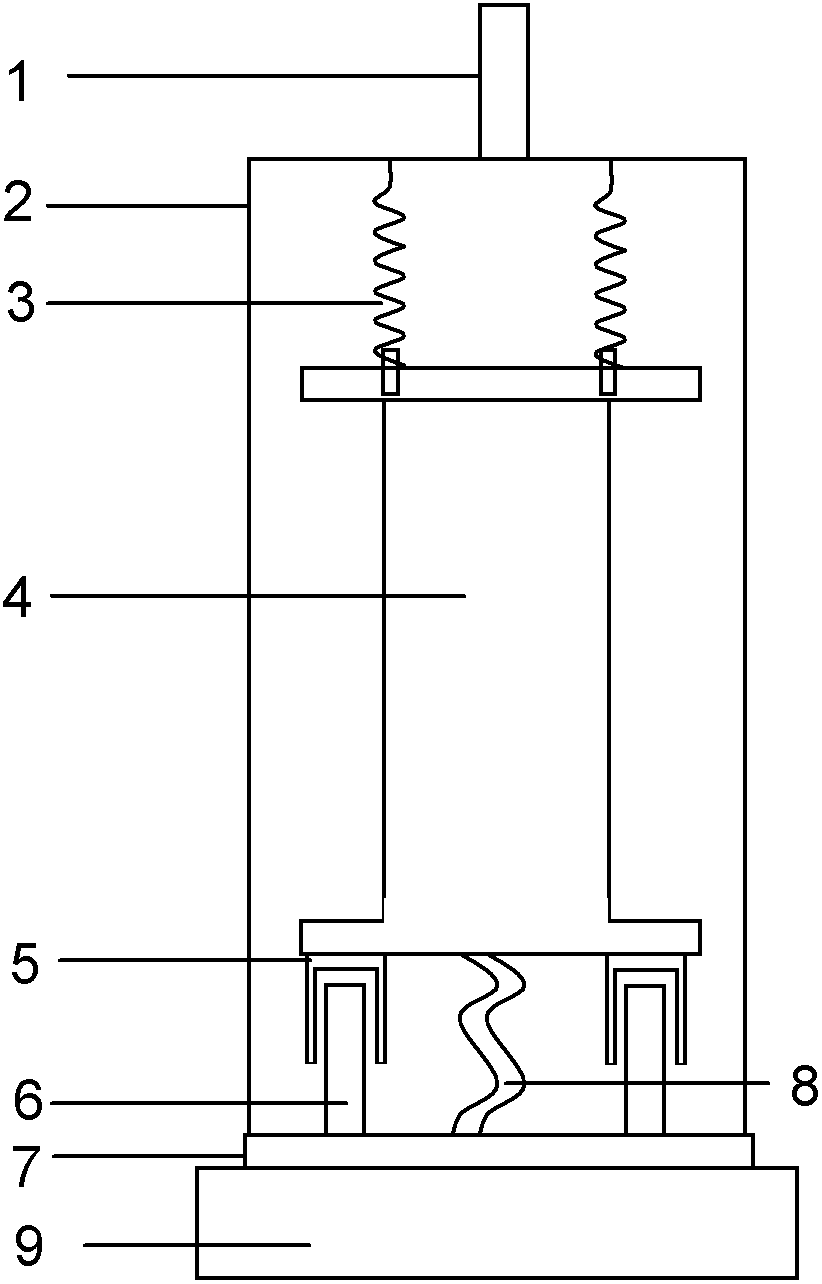

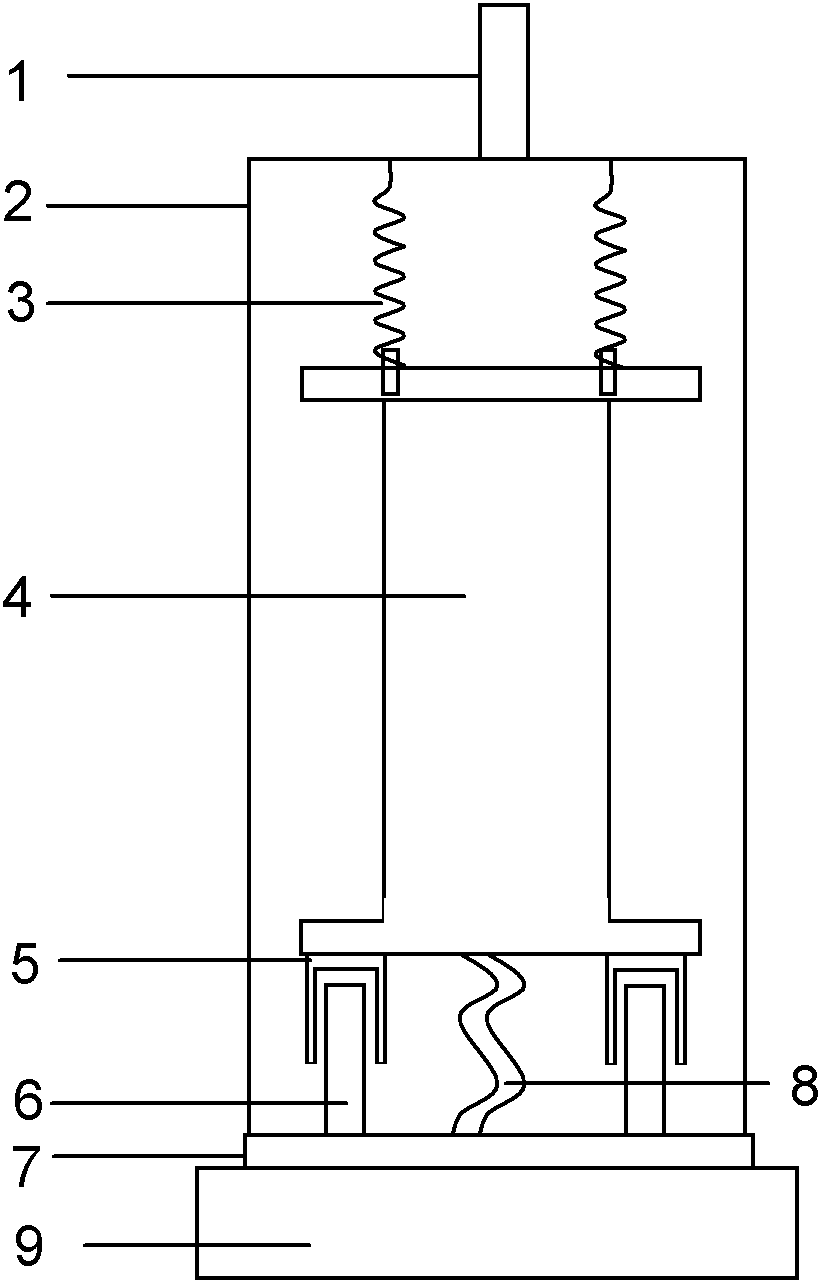

[0011] Referring to the accompanying drawings, the entire damping component is suspended on the lifting rod of the cryogenic cavity through a rigid hook 1 . The rigid hook 1 is connected to the center of the top of the metal sleeve 2 . The SNOM scanning head 4 is suspended on the top of the metal sleeve 2 by three springs 3 . Six copper frames 5 are fixed on the lower surface of the scanning head base, and the corresponding six square NdFeB magnets 6 fixed on the thermally conductive copper plate 7 are located in the middle of the copper frame, but do not contact the copper frame, forming a magnetic resistance Ni vibration damping device. When vibration occurs, on the one hand, the spring 3 damps the vibration, and on the other hand, the copper frame 5 moves along one side of the magnet 6 to cut the magnetic force line to cause magnetic damping, which plays the role of vibration reduction. The metal sleeve 2 is fixed to the bottom heat-conducting copper plate 7, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com