Double furnace body rotary furnace grate briquette coal boiler

A rotary furnace, double furnace technology, applied in the direction of fluid heaters, solid fuel combustion, combustion equipment, etc., can solve the problems of noise pollution, serious pollution, high electricity bills, etc., to reduce heat loss, reduce smoke pollution, save energy The effect of electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

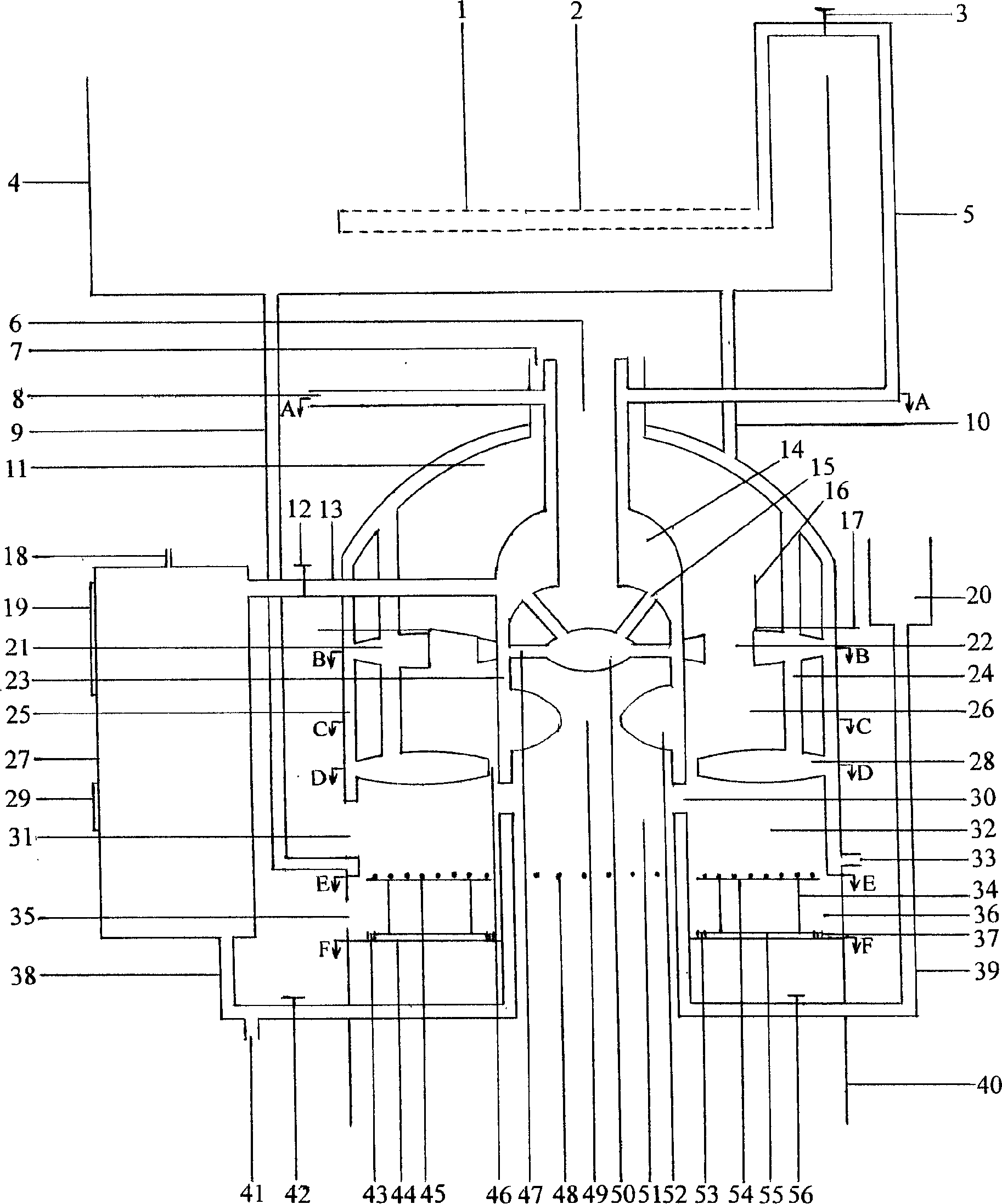

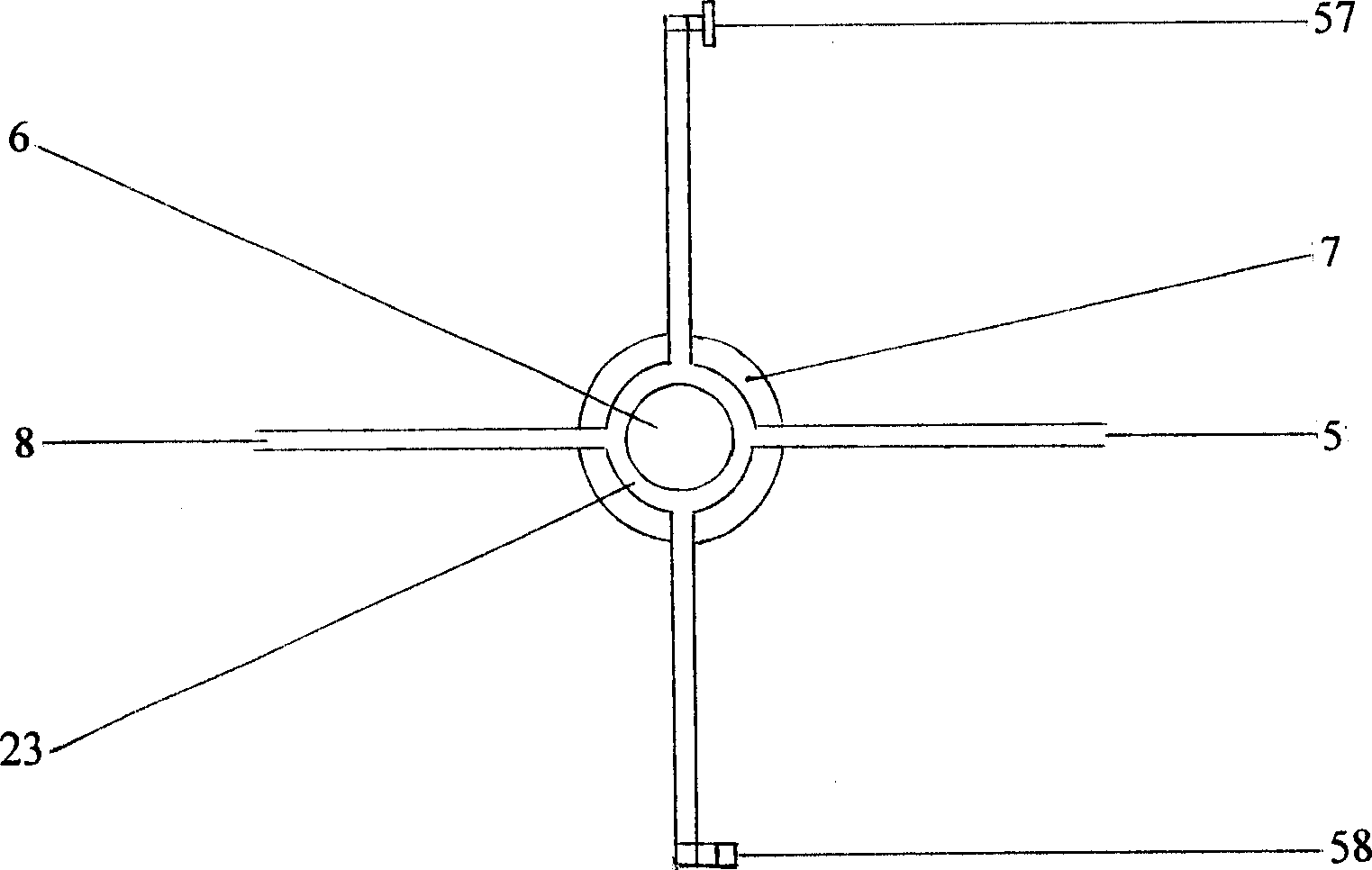

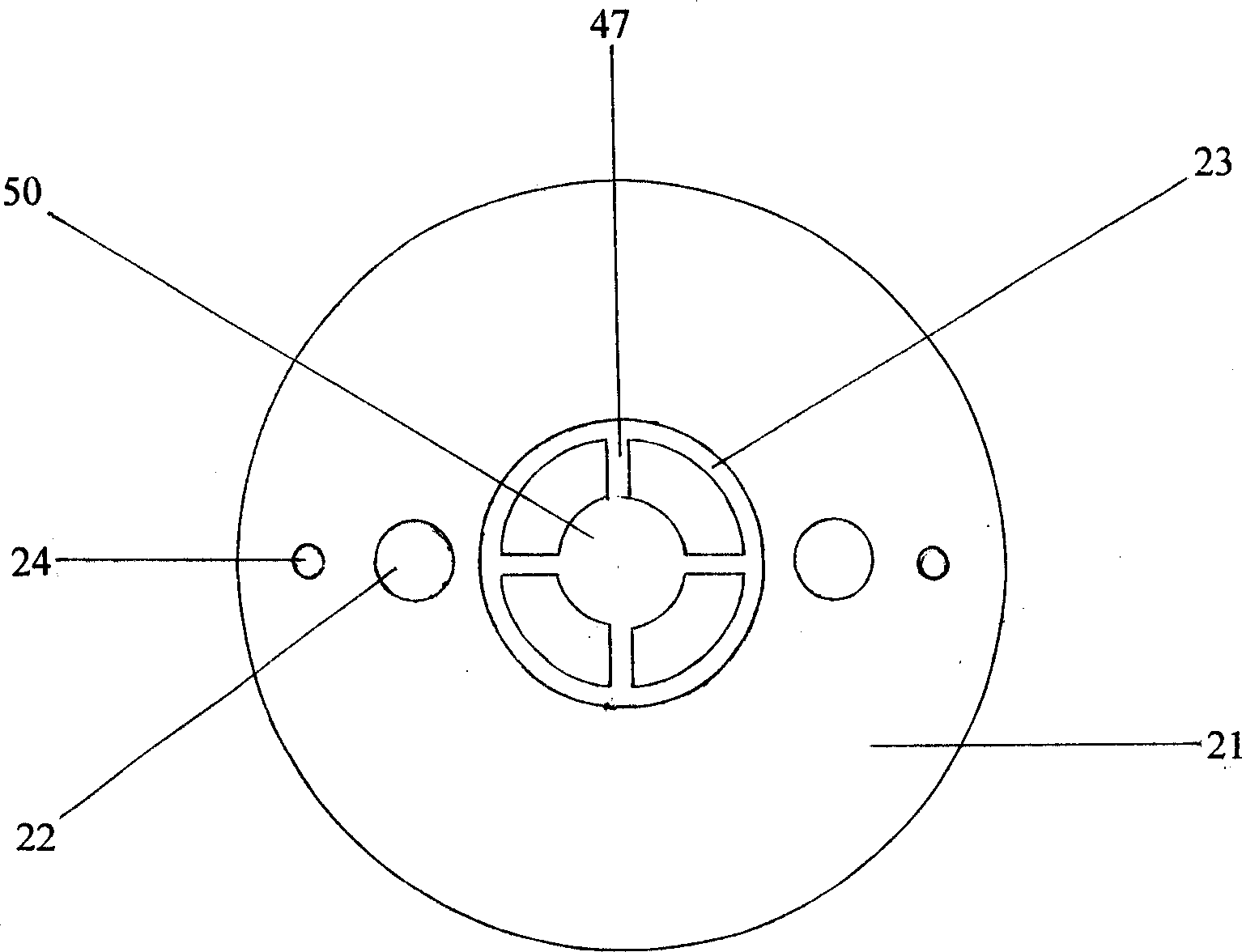

[0023] The double furnace body rotary furnace grate briquette boiler is composed of an outer combustion chamber 32 and a central combustion chamber 51. The cylindrical outer furnace body water layer 25 has a diameter of 162 cm and a height of 120 cm. Or circular briquettes, burn, turn the rotating disk 59 to drive the rotating teeth 60 to rotate, make the rotating grate 45 rotate clockwise or counterclockwise, and continue to put briquettes in the outer combustion chamber furnace door 31, all of which can place 360 pieces Briquettes can be controlled according to the quantity and burning speed of briquettes placed according to different needs such as heating or boiling water. The smoke burned in the combustion chamber 32 enters the combustion chamber 26 through the fire receiving flue 46, and then passes through the flue of the upper furnace body water layer. 22 enters the flue exhaust duct 11 of the outer layer combustion chamber and the exhaust port 7 and is discharged outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com