Solidification method of UV lacquer for coating object and its equipment

A technology of curing equipment and curing method, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problems of rough coating surface, UV paint coating curing, dust brought into the box, etc. , to achieve the effect of saving time, fast curing, and overcoming dust ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

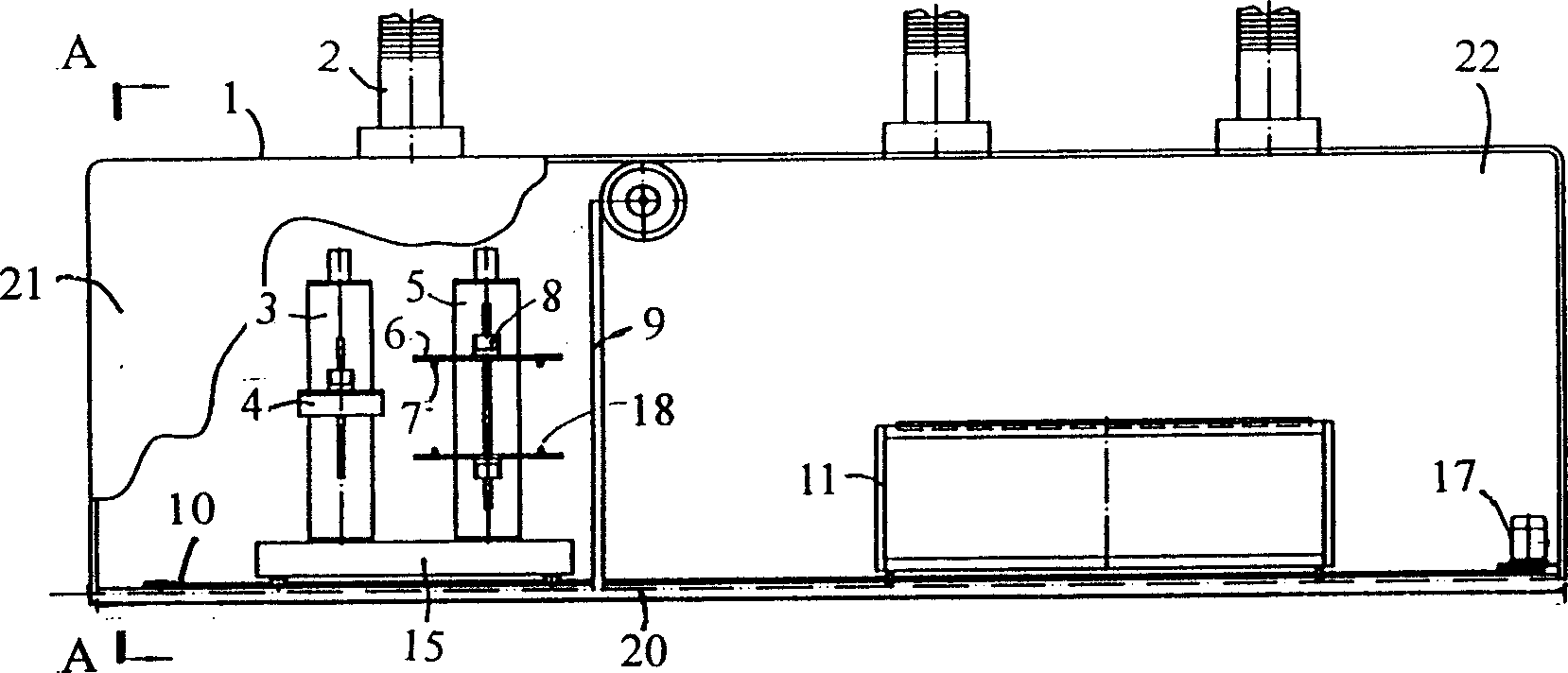

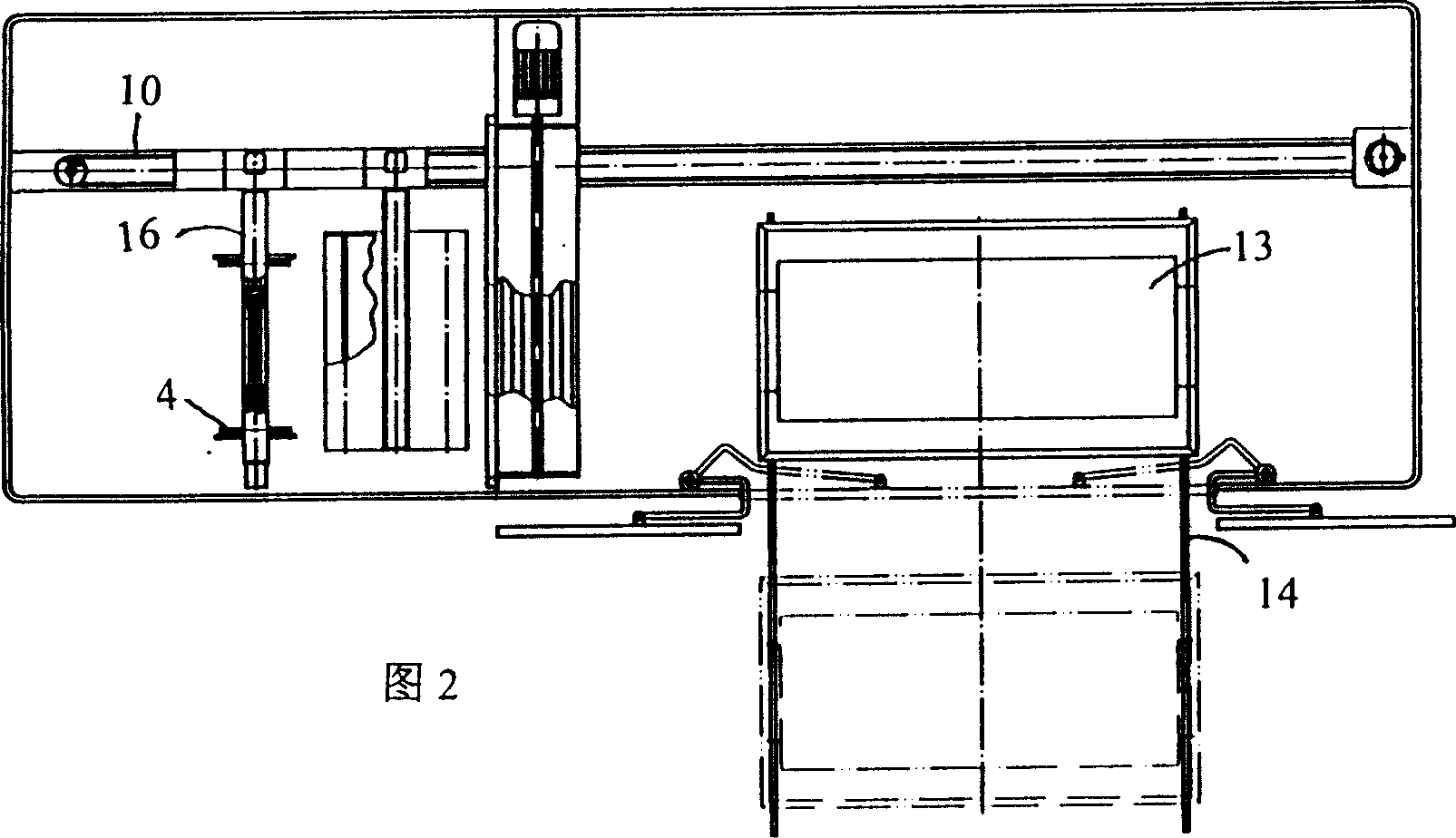

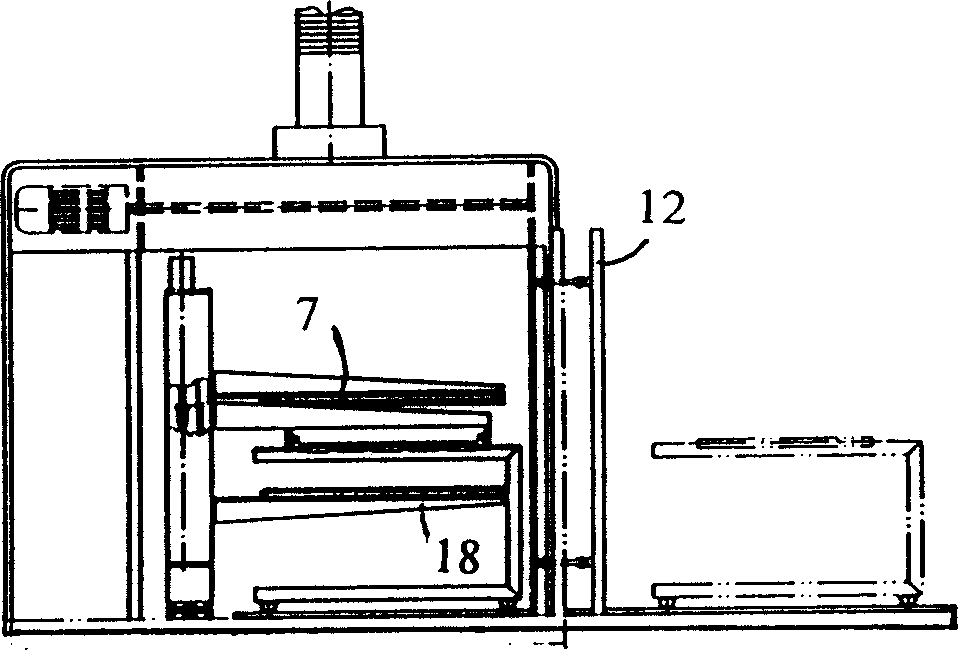

[0030] The low-temperature curing method of the UV paint of the present invention adopts ultraviolet light, and according to the requirements of the object to be cured, the position of the ultraviolet light source is arranged in the following forms:

[0031] When curing the upper surface and both sides of the object, the ultraviolet light source is set on the top and both sides of the object to be cured, and the light source on both sides and the upper light source are located on the same vertical plane perpendicular to the moving direction of the object, or relative to The direction in which objects move is staggered back and forth.

[0032] When curing the upper and lower surfaces and both side surfaces of the object at the same time, a lower light source is provided below the upper light source, and the upper and lower light sources are located on the same vertical plane perpendicular to the moving direction of the object, or relative to the moving direction of the object T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com