Adhesive preparation package

A technology for adhesive preparations and packaging products, which is applied in the direction of packaged food, packaged item types, packaging, etc., and can solve problems such as quality assurance and difficulty in finding tiny pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Lamination film using packaging film: transparent polyethylene terephthalate film (thickness: about 12 μm) / polyacrylonitrile resin film (product name: HIGHTORON BX, manufactured by TAMAPOLY CO., LTD., thickness: about 20 μm), under the following conditions, pack (encapsulate) an adhesive preparation (thickness: about 680 μm, size: 50 × 30.5mm) containing lidocaine as a drug for transdermal absorption with a heat-sealing treatment method to obtain the Shaped adhesive preparation packaging products.

[0097] Packaging product size: 50mm×70mm rectangular, flat heat-sealed part width: 0.5mm, embossed heat-sealed part width: 5mm, embossed heat-sealed part embossed pattern: 0.6mm pitch tatami mat texture-like dots, heat-sealed Method: Use a four-side sealing packaging machine for reciprocating sealing treatment, and use a metal mold to perform heat-sealing treatment on the four sides at the same time. The heat-sealing treatment temperature: 180°C, and the heat-sealing treat...

Embodiment 2

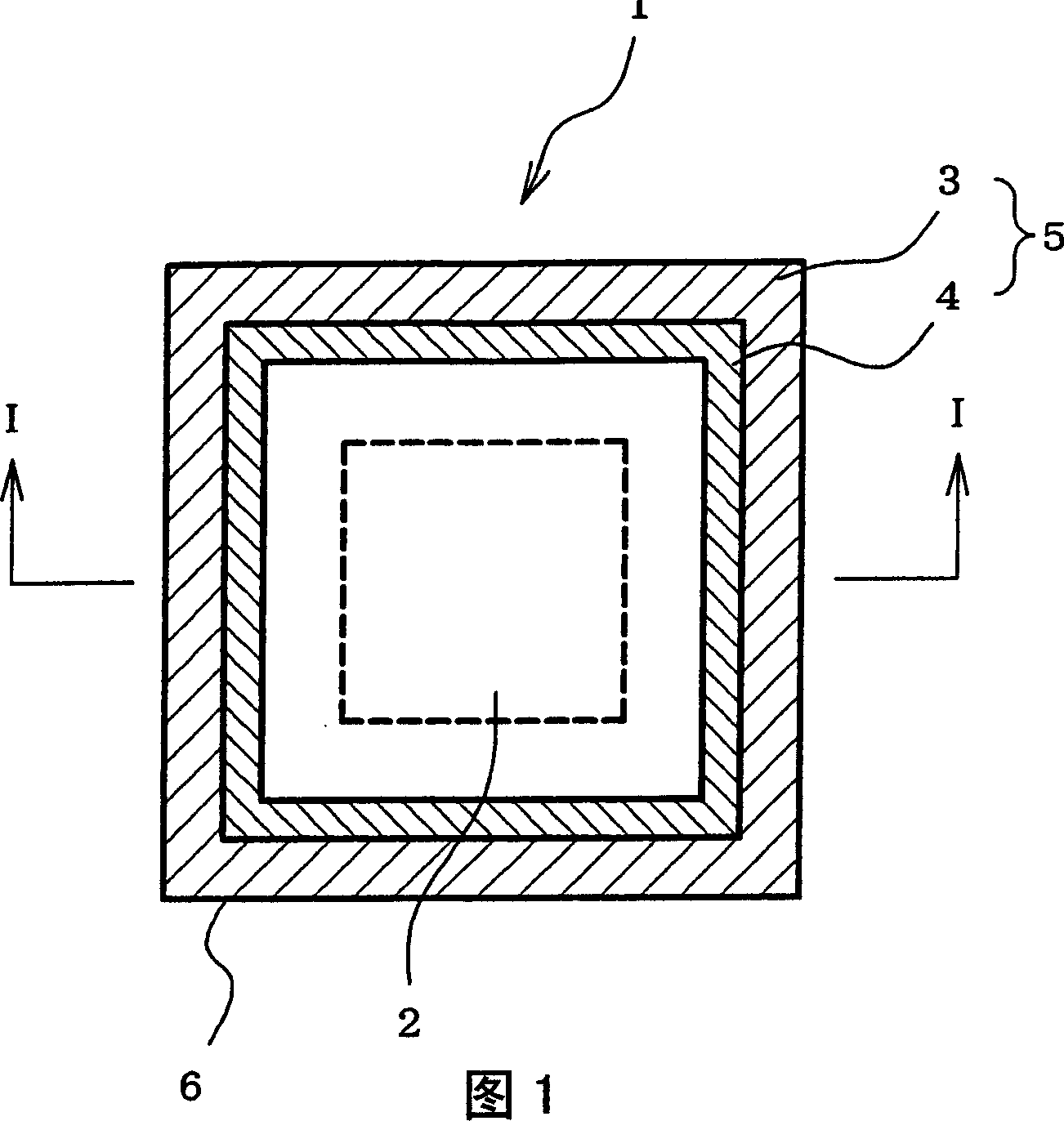

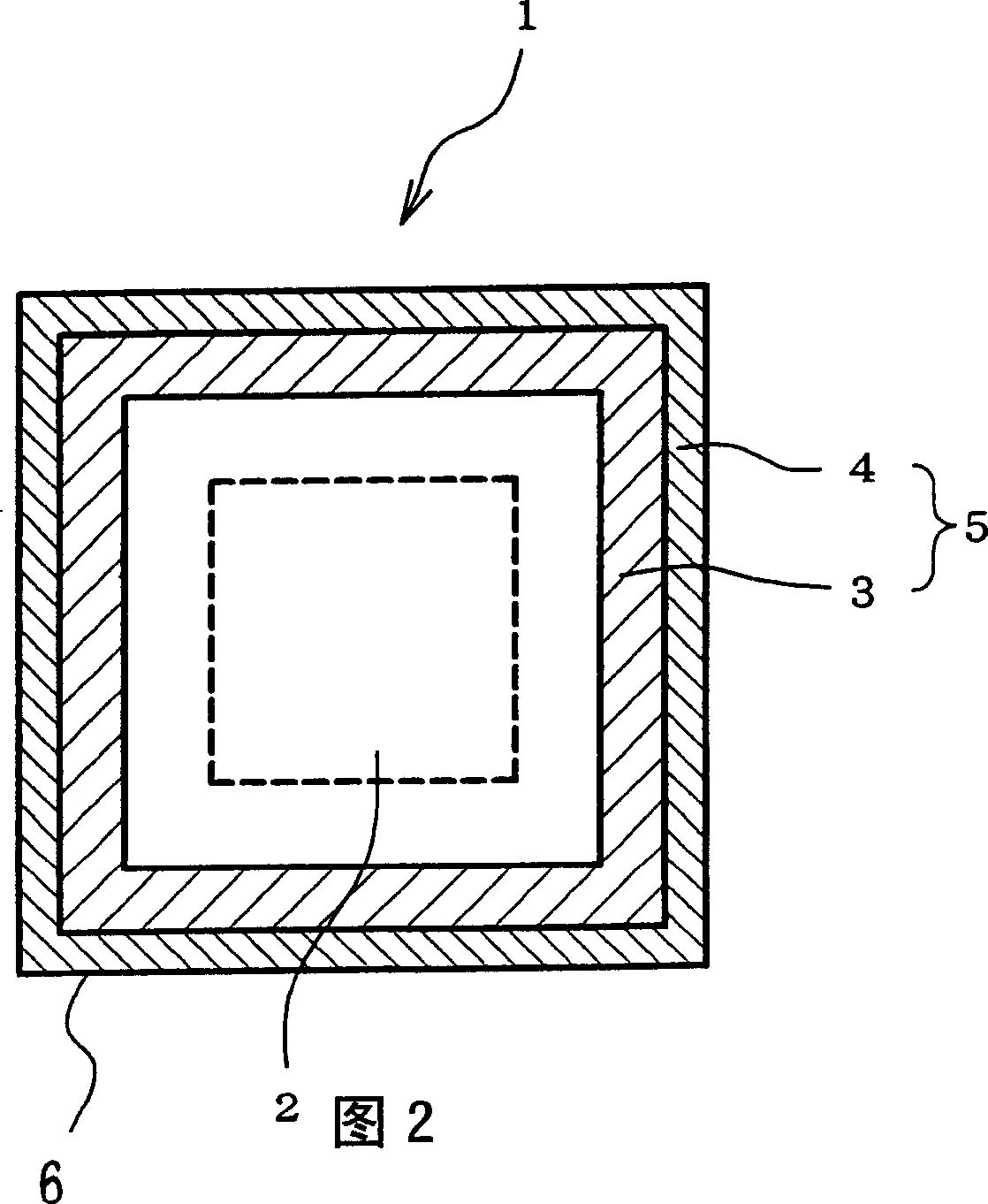

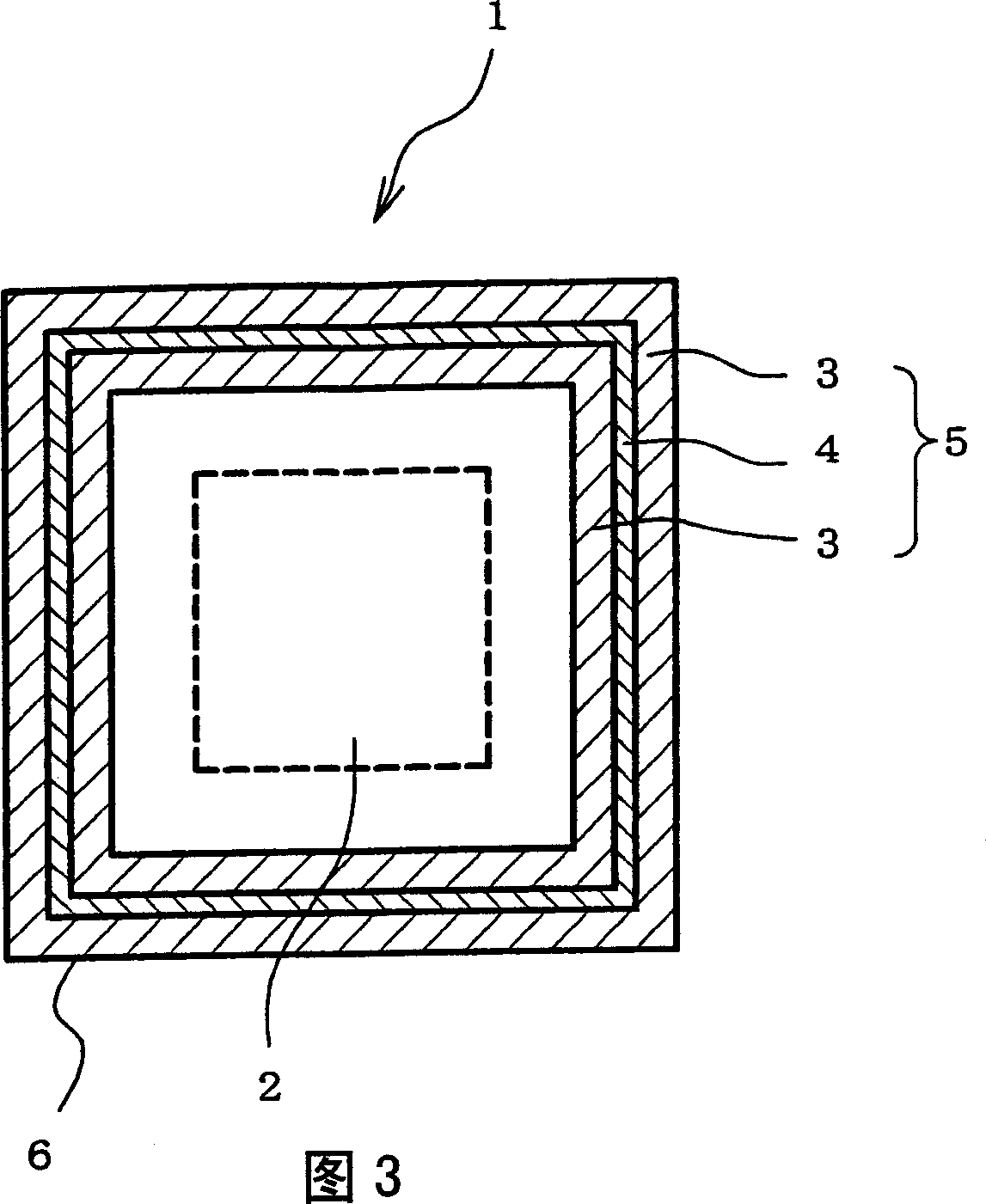

[0099] Lamination film using packaging film: Transparent polyethylene terephthalate film (thickness: about 16 μm) / polyethylene resin film (manufactured by Kaito Chemical Industry Co., Ltd., thickness: about 40 μm) in the following Packaging (encapsulation) containing isosorbide dinitrate (ISDN) as the adhesive preparation (thickness: about 140 μ m, size: 63.5 × 63.5 mm) of transdermal absorption drug with the heat-sealing treatment method under the condition, obtains and has the shape shown in Fig. 1 Adhesive preparation packaging products.

[0100] Packing size: 85mm×85mm square, width of flat heat-sealed part: 1.0mm, width of embossed heat-sealed part: 7mm, embossed pattern of heat-sealed part: 7mm spacing of tatami mat texture-like dots, heat-sealing treatment method: A four-side sealing packaging machine is used for reciprocating treatment, and the four sides are simultaneously heat-sealed with a metal mold. The heat-sealing temperature: 140°C, and the heat-sealing pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com