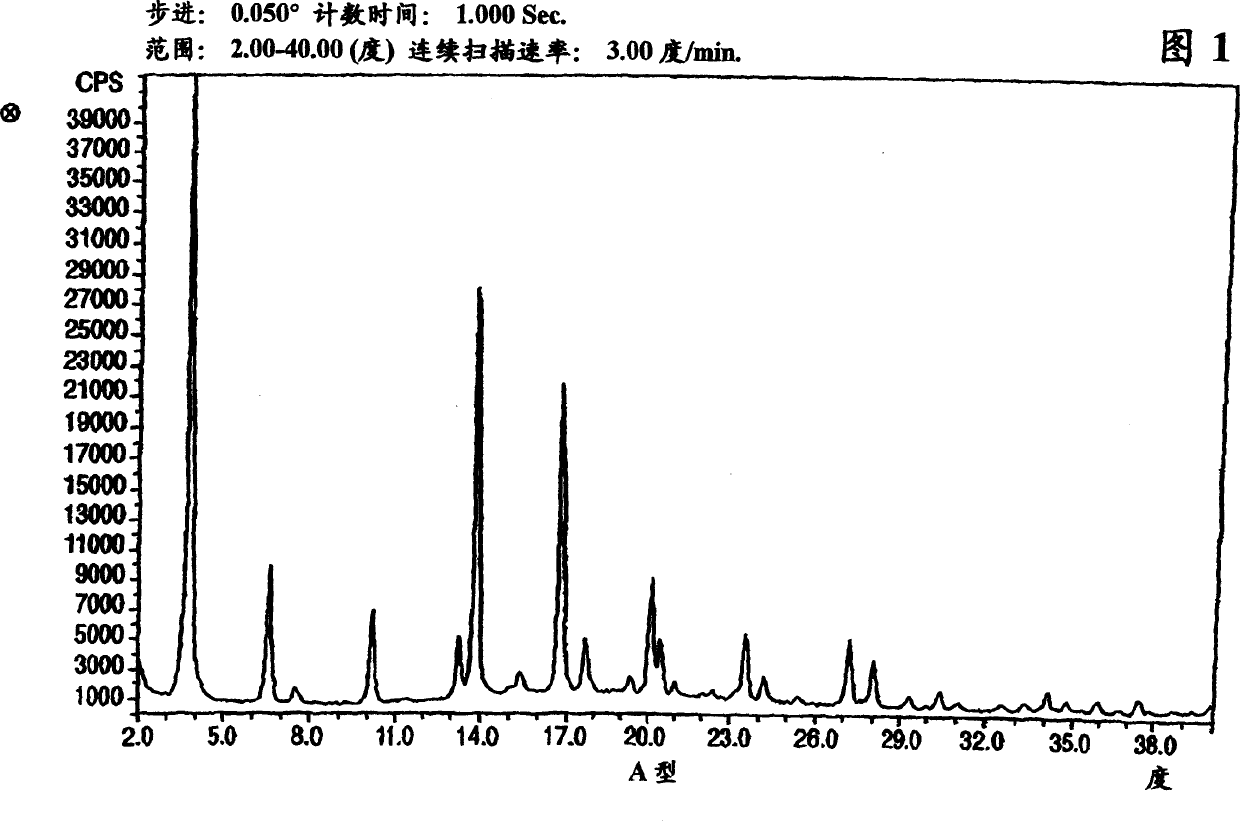

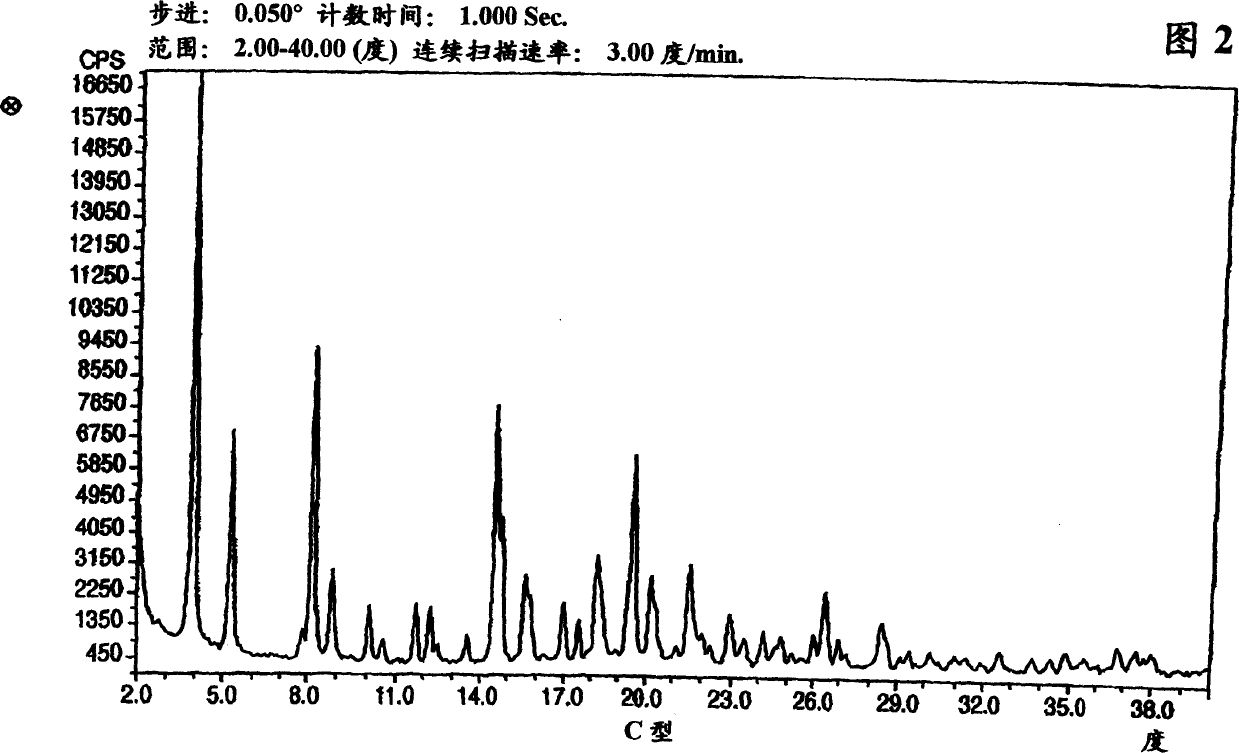

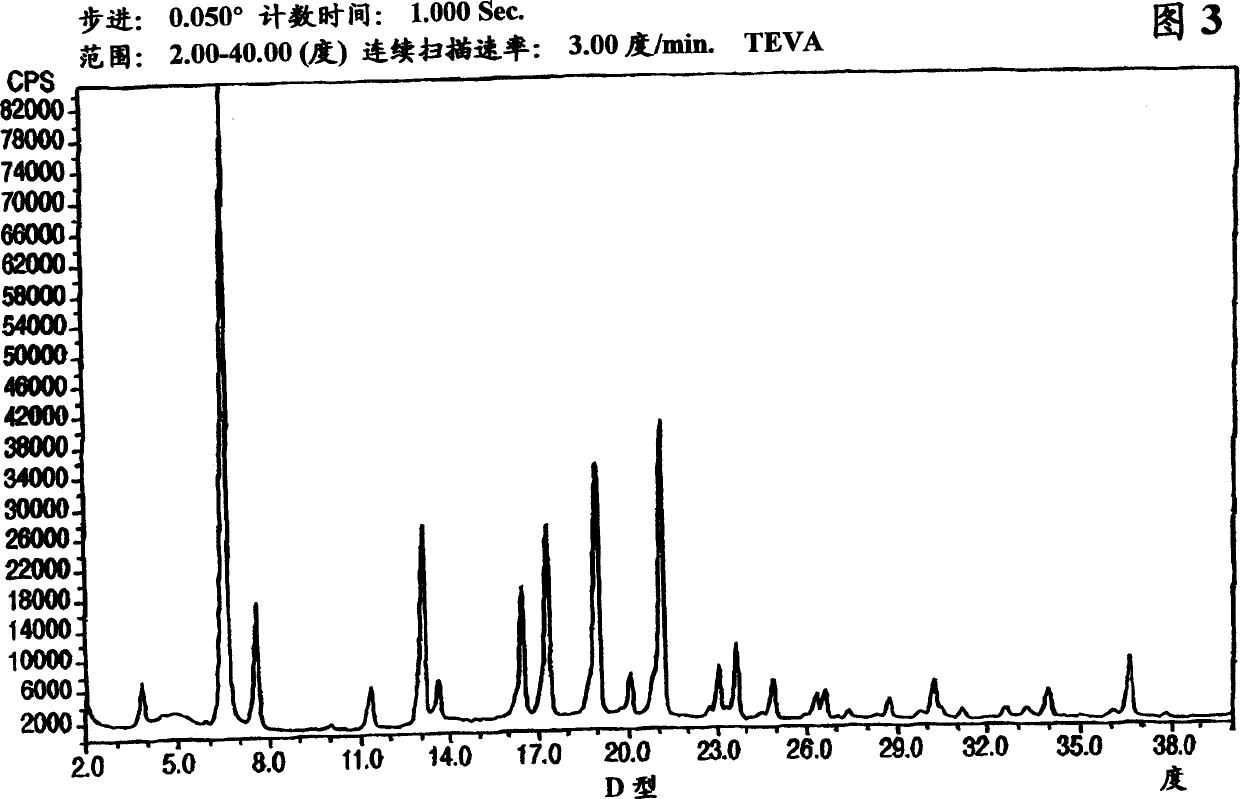

Polymorphic forms of nateglinide

A technology of nateglinide and crystal form, applied in the field of solid-state chemistry, can solve the problems of unstable and easy-to-change B-type crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0193] Example 1 - This example illustrates the preparation of various nateglinide crystal forms from solution

[0194] Nateglinide (5g) was placed in an Erlenmeyer flask and heated to a specific temperature. The solvent was added in 1 ml portions (in some cases in 5 ml portions) until a clear solution formed. If a clear solution did not result after addition of 150 ml of the solvent, the hot mixture was filtered.

[0195] The clear solution crystallized at room temperature. If no or very few crystals appeared, the solution was frozen at 3°C. The precipitate was filtered off (at room temperature or 5°C, depending on the crystallization temperature), weighed and divided into two equal portions. One portion was dried at 50°C under reduced pressure (20-30mmHg) for about 3-10 hours to constant weight (±0.01g). Details are listed in Table IV.

[0196] solvent

L / S,

ml / g

T,

℃

time

RT, h

time

3°C, h

crystal form

wet

...

Embodiment 2

[0200] Example 2 - This example illustrates the milling of Form H and U nateglinide in various solvents

[0201] Nateglinide (5g) was placed in an Erlenmeyer flask. The solvent was added in 1 ml portions to prepare a stirrable mixture. The bottle was stirred at room temperature with a magnetic stirrer. The solid was filtered off at room temperature, weighed, and divided into 2 equal portions. One portion was dried at 55°C under a pressure of 20-30mm / Hg to constant weight (±0.01g).

[0202] Details are listed in Tables V and VI.

[0203] start

[0204] start

Embodiment 3

[0205] Example 3 - This example illustrates the absorption of nateglinide to solvent vapor

[0206] Nateglinide (3.50 g) was added to a polypropylene jar and weighed. The jars were introduced into a larger polypropylene container containing solvent and stored at room temperature. The jar was removed from the container and weighed (Wfinal). The can contents are divided into 2 parts. One portion was dried to constant weight (±0.01 g) at 55°C under 20-30 mmHg pressure. Details are listed in Table VII.

[0207] NTGW,

[0208] Legend: Brutto - start weight of tank with NTG; Wfinal - final weight of tank with NTG after exposure; Δ - excess weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com