Exposure apparatus and method for producing device

An exposure device and exposed technology, used in semiconductor/solid-state device manufacturing, photolithographic process exposure devices, microlithography exposure equipment, etc., can solve the problems of rust, inability to maintain cleanliness, and failure to obtain pattern transfer accuracy. , to achieve the effect of inhibiting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

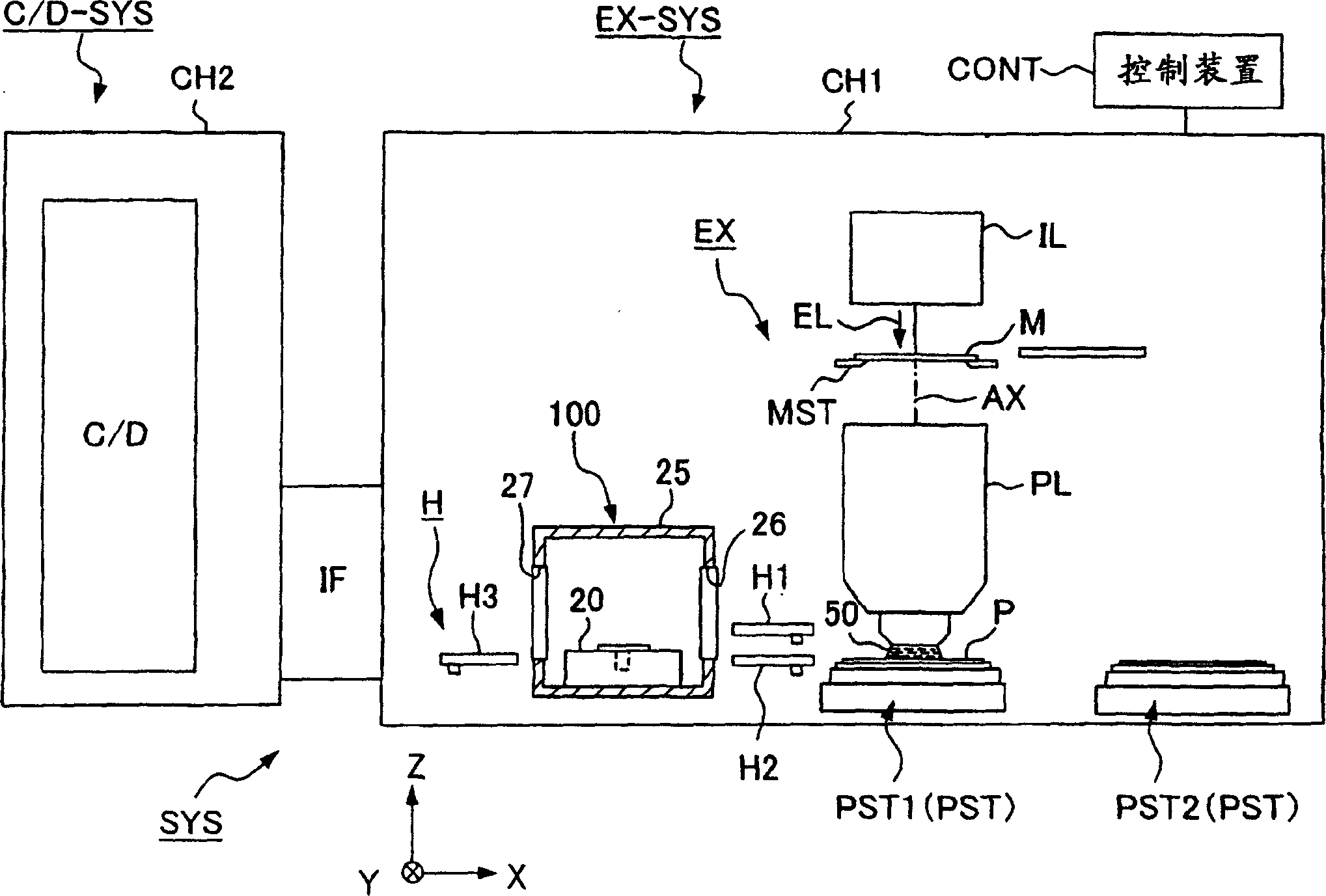

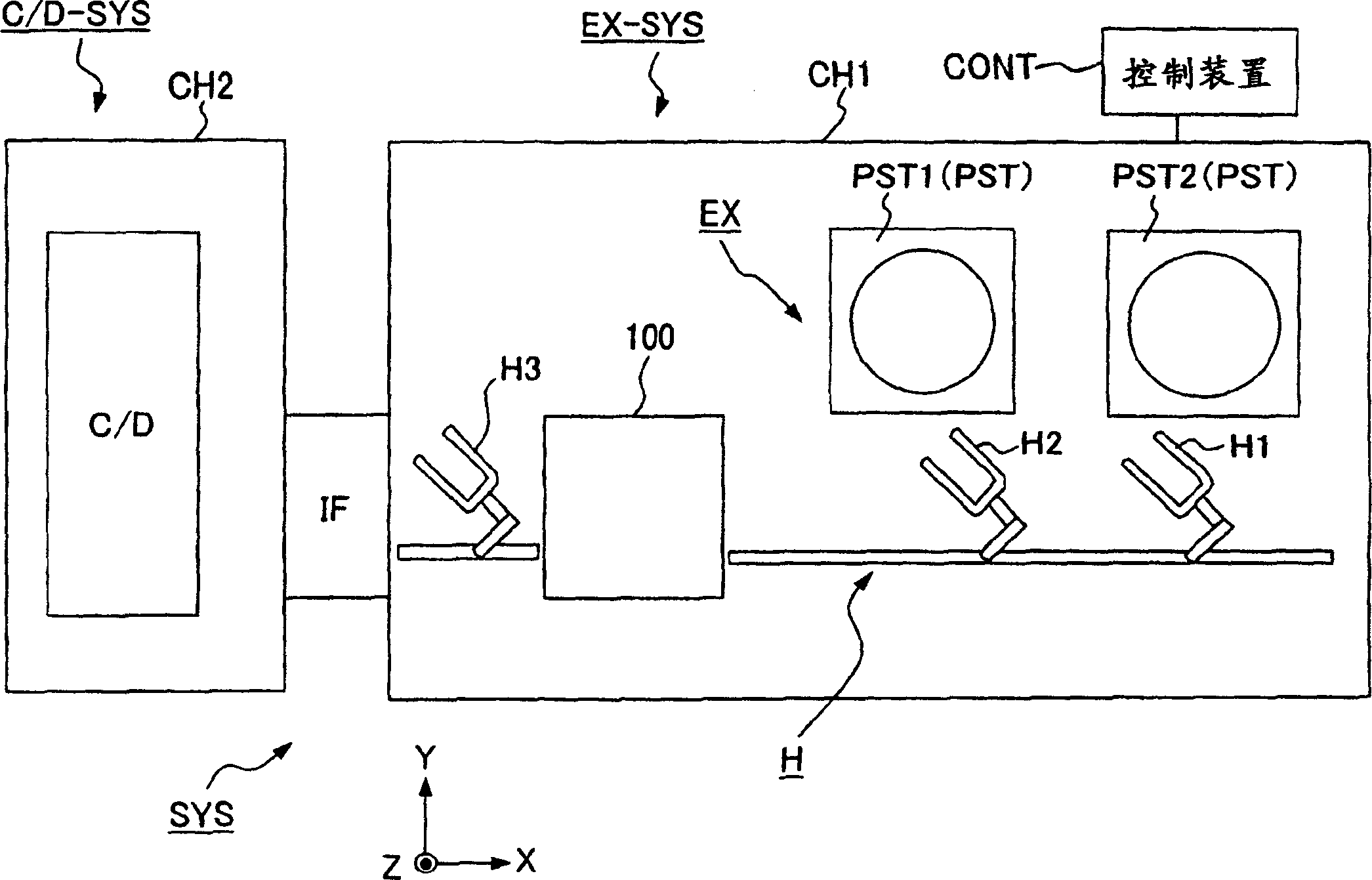

[0047] Below, while referring to the attached Figure 1 Next, the exposure apparatus and device manufacturing method of the present invention will be described. figure 1 It is a figure which shows one embodiment of the device manufacturing system which has the exposure apparatus of this invention, and the schematic structural figure seen from the side, figure 2 is viewed from above figure 1 diagram.

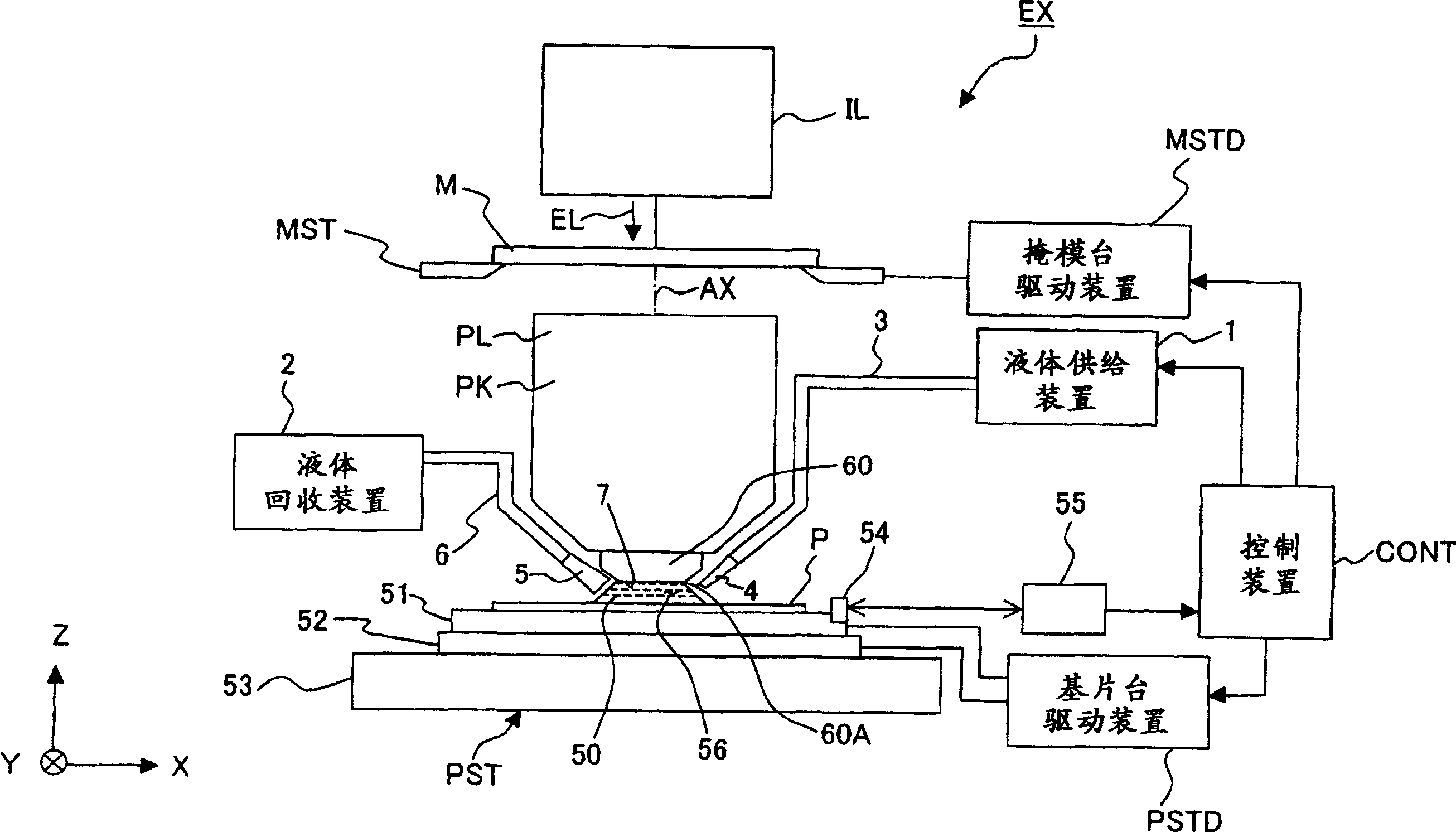

[0048] exist figure 1 , figure 2 Among them, the device manufacturing system SYS has an exposure device EX-SYS and a coater / developer device C / D-SYS. The exposure device EX-SYS has: an interface part IF forming a connection part with the applicator-developer device C / D-SYS, and the space between the projection optical system PL and the substrate P is filled with liquid 50, and the projection optical system PL PL and the liquid 50 project a pattern image onto the substrate P and expose the substrate P to the exposure apparatus body EX, and a transfer system H for transfe...

no. 2 Embodiment approach

[0085] Next, the liquid removal device 100 used in the exposure device according to the second embodiment of the present invention will be described with reference to FIG. 6 . Here, in the following description, descriptions other than the liquid removal device 100 are simplified or omitted because they are the same or equivalent to those of the first embodiment.

[0086] In FIG. 6, the liquid removal device 100 is provided with a cover portion (cover) constituting a part of a cover mechanism covering the periphery of the substrate P in order to prevent the liquid 50 from splashing when removing the liquid 50 attached to the substrate P. )30. The liquid removal device 100 in this embodiment does not have the chamber 25 . The cover portion 30 is formed in a substantially annular shape in plan view, and has a pocket portion 30A inside the annular ring. The liquid suction device 29 is connected to the groove portion 30A of the cover portion 30 . Moreover, the cover part 30 can...

no. 3 Embodiment approach

[0089] Next, while referring to Figure 7 The liquid removal device 100 used in the exposure device of the third embodiment will be described. The characteristic part of this embodiment is that the rotation mechanism 22 and the cover part 30 constituting the liquid removal apparatus 100 are provided on the substrate stage PST of the exposure apparatus body EX that performs exposure processing. Since the structure of the exposure apparatus main body EX is the same as that of the first embodiment, description thereof will be omitted.

[0090] exist Figure 7 In (a), the substrate stage PST has the holder part 21 and the second holder part 24 which hold the substrate P, and the recessed part 31 which can accommodate the cover part 30. As shown in FIG. Then, if Figure 7 As shown in (a), the pattern image is transferred to the substrate P held on the holder unit 21 and the second holder unit 24 through the projection optical system PL and the liquid 50 . Once the exposure proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com