SiGe strain relaxed buffer for high mobility devices and a method of fabricating it

A buffer layer and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as material consumption, low-line dislocation, and non-active device areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

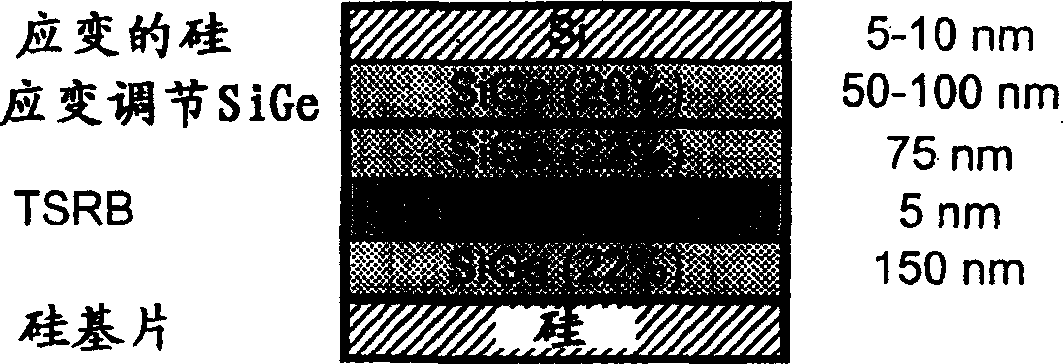

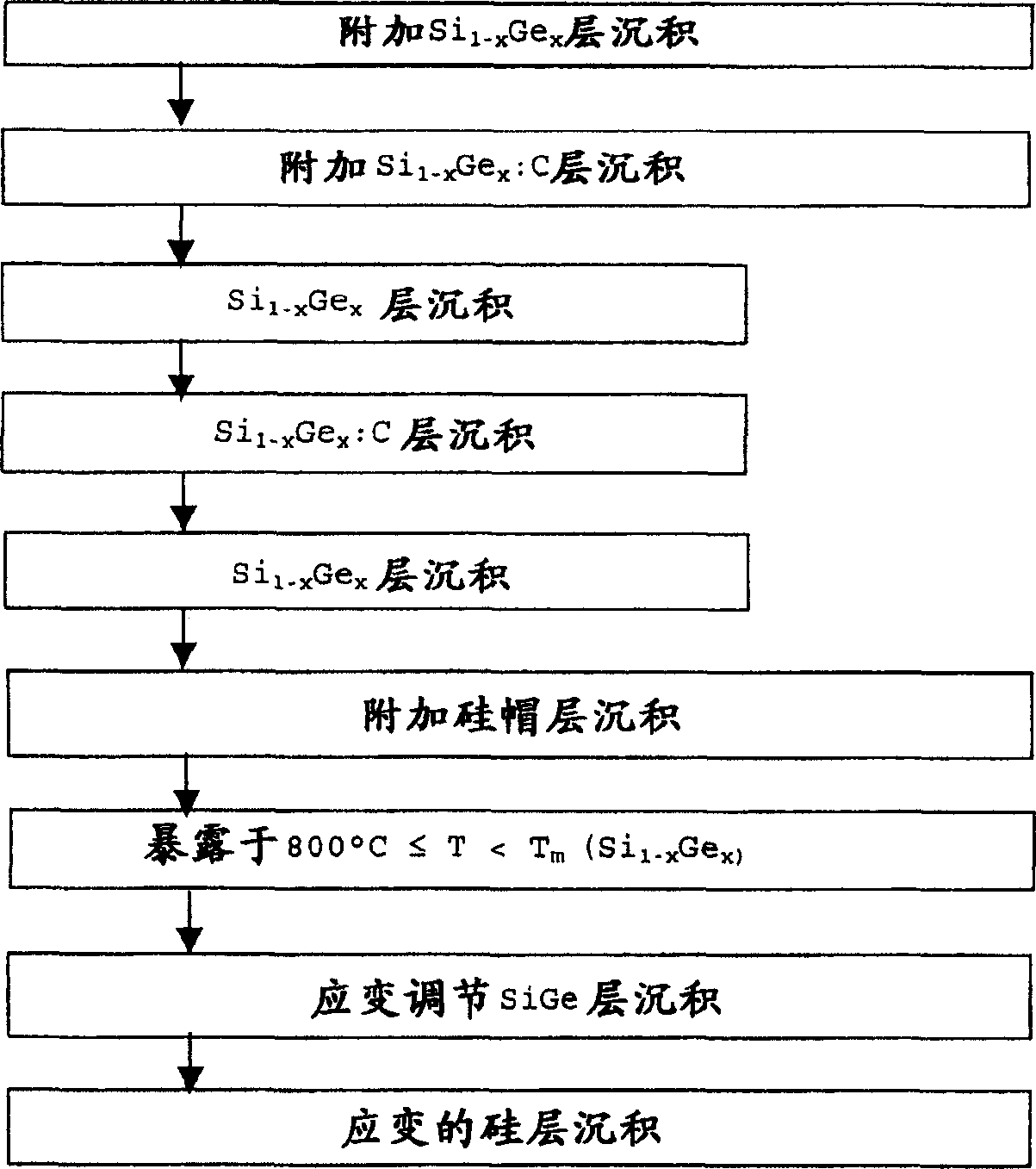

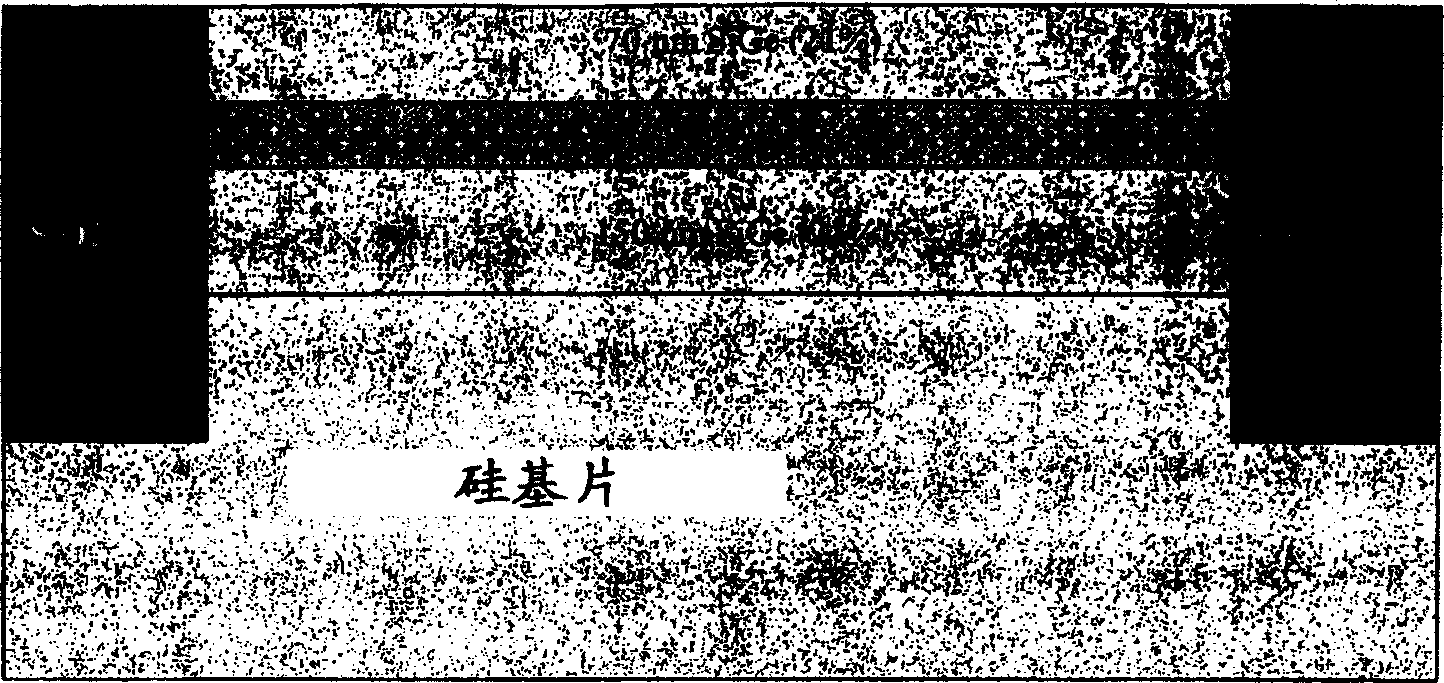

[0055] The present invention relates to a Thin Strain Relaxation Buffer (TSRB) for the integration of high mobility devices (eg SiGe / strained Si systems) on top of a semiconductor substrate such as silicon. In the following description, thin strain buffer layers and methods for obtaining them are explained.

[0056] in Si 0.78 Ge 0.22 / Si 0.78 Ge 0.22 :C y / Si 0.78 Ge 0.22 Epitaxial growth of TSRB on the basis of a multilayer system with a y (C concentration) of at least 0.3%, preferably between 0.5% and 1%, yielded 91% after rapid thermal annealing (30" at 1000°C) of Relaxed, with a very smooth surface (RMS-1 nm). No dislocations reaching the surface of the epitaxial layer were observed. To create heterocenters for dislocation nucleation, carbon was introduced during the growth of SiGe with the in situ method.

[0057] figure 1 shows the complete structure of a 230 nm TSRB on a silicon substrate with a SiGe / Si heterosystem deposited on top according to the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com