Multi-nozzle enclosed type middle and low pressure water mist sprayer

A technology of fine water mist nozzles and multi-nozzles, applied in the direction of spraying devices, spraying devices, etc., can solve problems such as unusable, expensive, water pollution loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

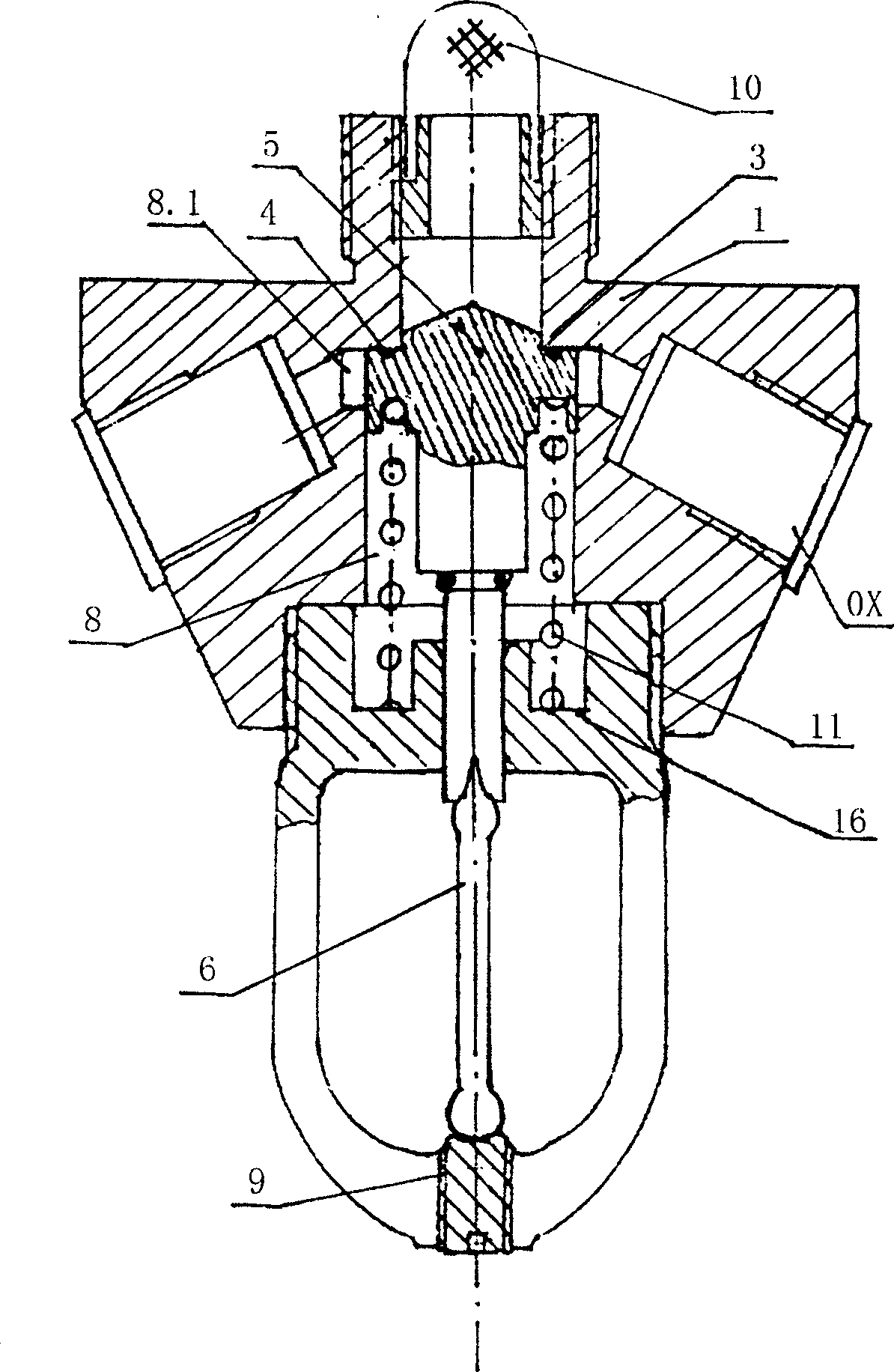

[0097] Embodiment 1: Schematic diagram of a multi-nozzle closed medium and low pressure fine water mist nozzle with a joint nozzle frame at the bottom of the nozzle seat, see figure 1 . The central hole of the nozzle seat of this embodiment is equipped with a filter 10, and the outlet 3 of the central hole of the nozzle seat is blocked by the top surface of the sealing piston 5 with a sealing ring 4, and the upper part of the sealing piston is located in the center of the outlet ring groove 8.1 of the intermediate cavity, and the sealing The stepped column with a small sealing ring at the lower part of the piston is located at the lower part of the middle cavity 8, and passes through the central hole of the annular groove disc 16, and its bottom is tightly held by the temperature-sensitive glass bubble 6, and the adjusting member 9 at the bottom of the frame supports the temperature-sensitive glass Bubble, the ring-shaped groove disc 16 with external threads on the upper part ...

Embodiment 2

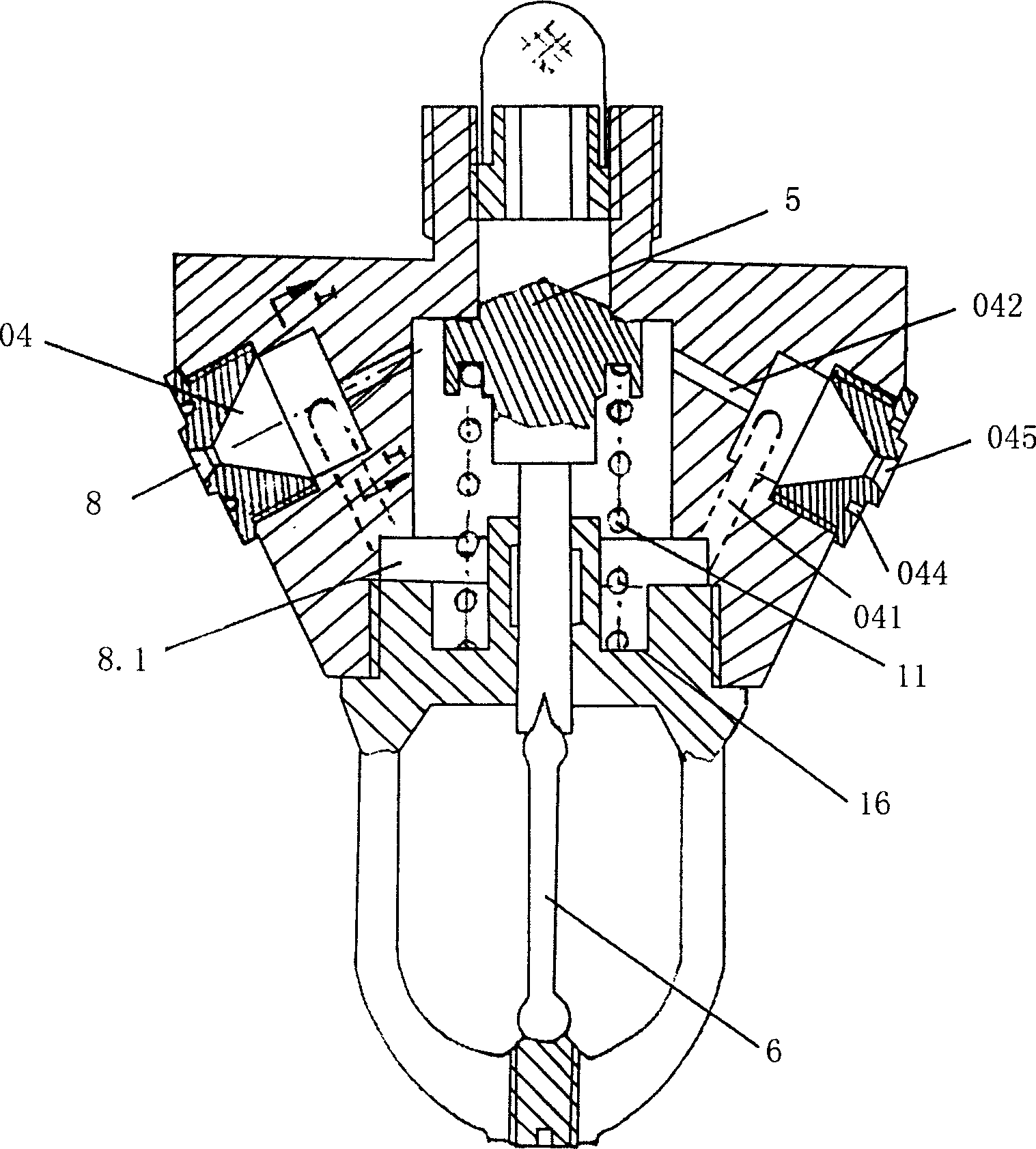

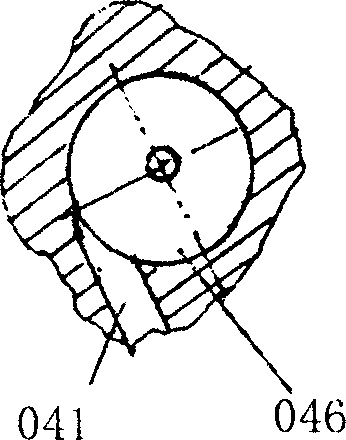

[0098] Example 2: For a schematic diagram of a multi-nozzle closed medium-low pressure fine water mist nozzle with jet swirl compound atomization core, see Figure 1.1 and 1.2 . The nozzle given in this embodiment is similar to the nozzle in Embodiment 1, except that the atomizing cores around the nozzle seat are jet swirl atomizing cores 04 . It consists of atomizing core round hole 046, atomizing core cap 044, central jet channel 042 and tangential swirl hole 041. The large end of the inner tapered hole of the atomizing core cap is equal to the diameter of the atomizing core round hole and closely connected with each other. The small end of the tapered hole in the inner chamber of the atomizing core cap shrinks into the nozzle of the atomizing core 045; the shoulder of the outlet ring groove 8.1 is provided with the entrance of the swirl hole 041, and the other end of the swirling hole is connected to the round hole 046 of the atomizing core and is tangent to it (See Fig...

Embodiment 3

[0099] Embodiment 3: Schematic diagram of a multi-nozzle closed medium-low pressure fine water mist nozzle with adjustable springs at the bottom of the nozzle seat, see figure 2 . The nozzle structure of this embodiment is basically the same as that of Embodiment 1. Parts 1, 4, 6, 10, 11, 0X, and intermediate chambers 8 and 8.1 are also similar to Embodiment 1, and will not be described again. The difference is that the center of the nozzle seat A multi-channel diversion grid bubble homogenizer 15 is arranged in the hole, the lower frame of the nozzle holder is integrated with the nozzle holder, and an annular groove disc screw plug 17 is arranged in the center of the bottom of the middle cavity, and the spring 11 can be adjusted to the sealing disc 5 by turning the screw plug 17. preload pressure. A pressure ring 12 with a sealing ring is arranged in the center hole of the nozzle seat, which is used to seal the outlet of the center hole of the nozzle seat together with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com