Print circuit board with improved heat rejection structure and electronic device

A technology of printed circuit board and heat dissipation structure, which is applied in the direction of printed circuit parts, printed circuits and circuits connected with non-printed electrical components, and can solve the problems of inability to provide heat dissipation effect, inability to dissipate heat, high heat dissipation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

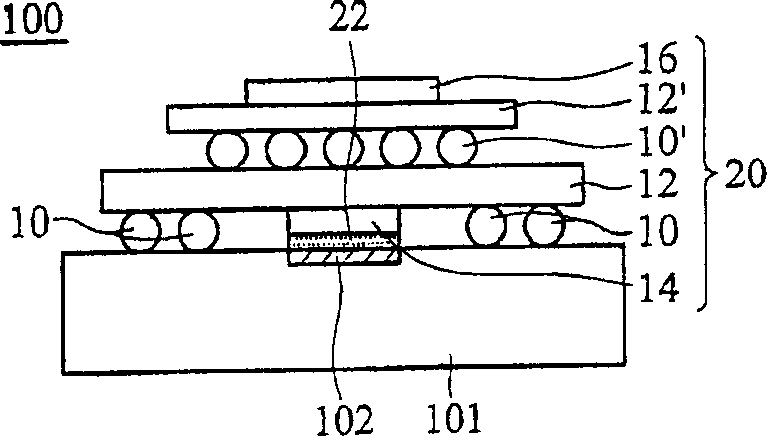

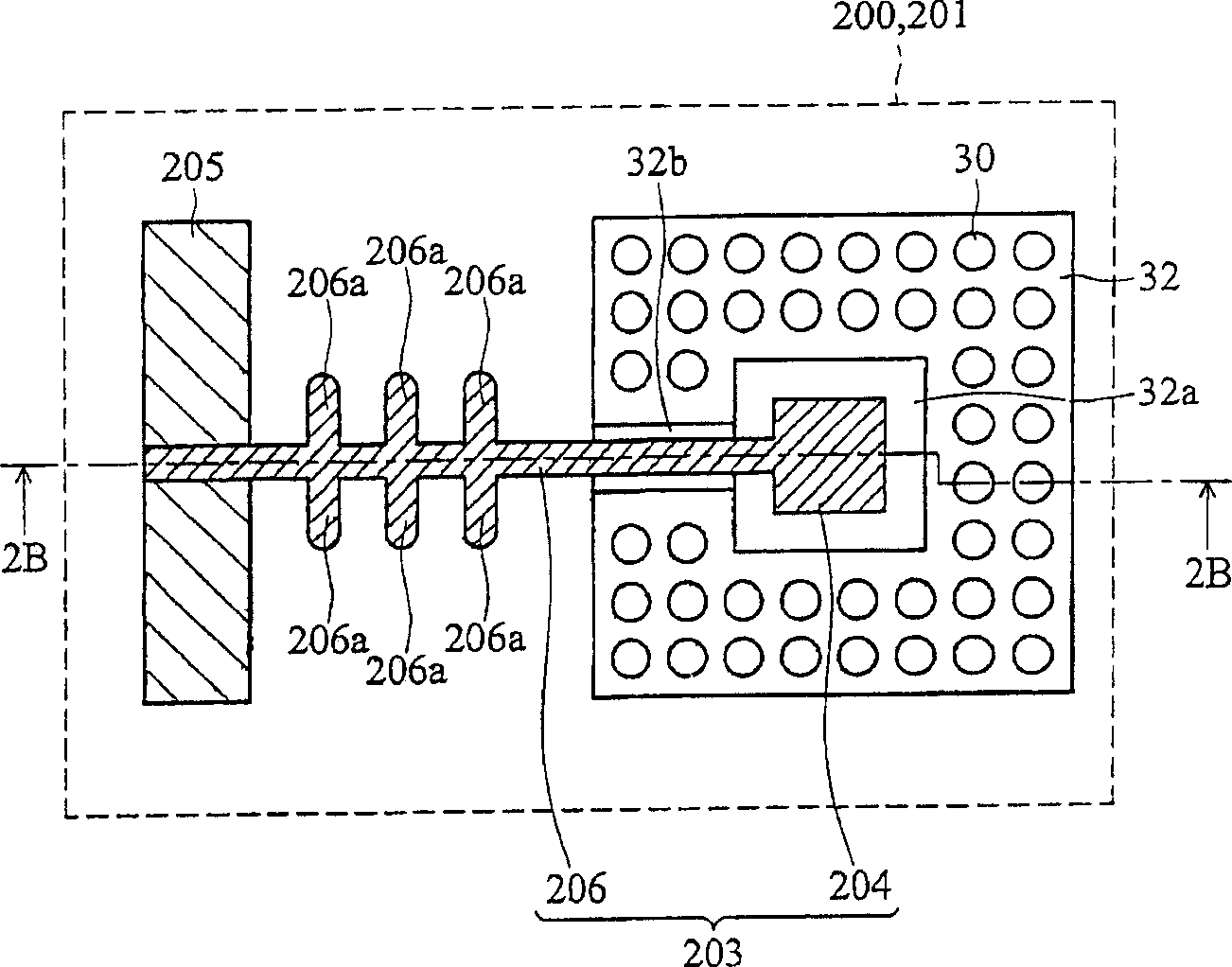

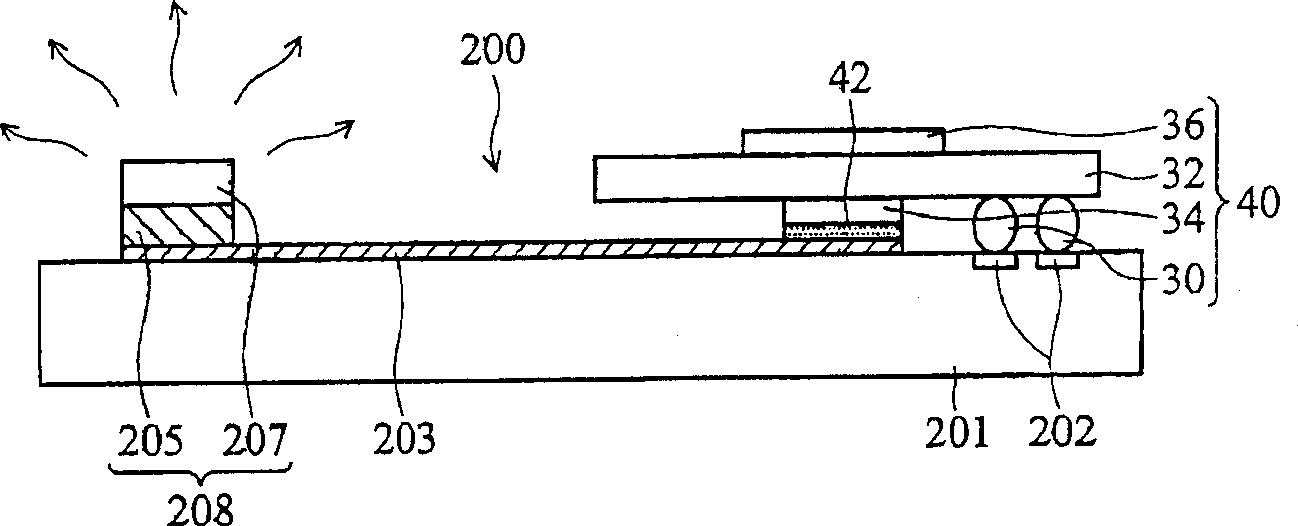

[0030] The following fit Figure 2A and 2B An electronic device with an improved heat dissipation structure is described according to an embodiment of the present invention, wherein Figure 2A A schematic bottom plan view of an electronic device with an improved heat dissipation structure according to an embodiment of the present invention is drawn, and Figure 2B draw the edge Figure 2A Schematic cross-sectional view of line 2B-2B. The electronic device includes: a multi-package module 40 with improved heat dissipation structure, a circuit board 200 and a heat sink 203 .

[0031] Please refer to Figure 3A and 3B ,in Figure 3A A schematic bottom plan view of a multi-package module 40 with an improved heat dissipation structure according to an embodiment of the present invention is shown, and Figure 3B draw the edge Figure 3A Schematic cross-sectional view of line 3B-3B. The multi-package module 40 includes a package substrate 32 . The lower surface of the packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com