Method for constructing a rigid track and a communication track

A roadway and solid technology, applied in the field of solid roadway, can solve the problems of long construction time and high construction cost, and achieve the effect of cost saving, high load-bearing capacity, material and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is illustrated in detail with the following examples, based on a solid pavement using precast concrete elements. However, the present invention is not limited thereto, but the present invention can also be used when a solid pavement is constructed using cast-in-place concrete, or a combination of cast-in-place concrete and precast concrete members.

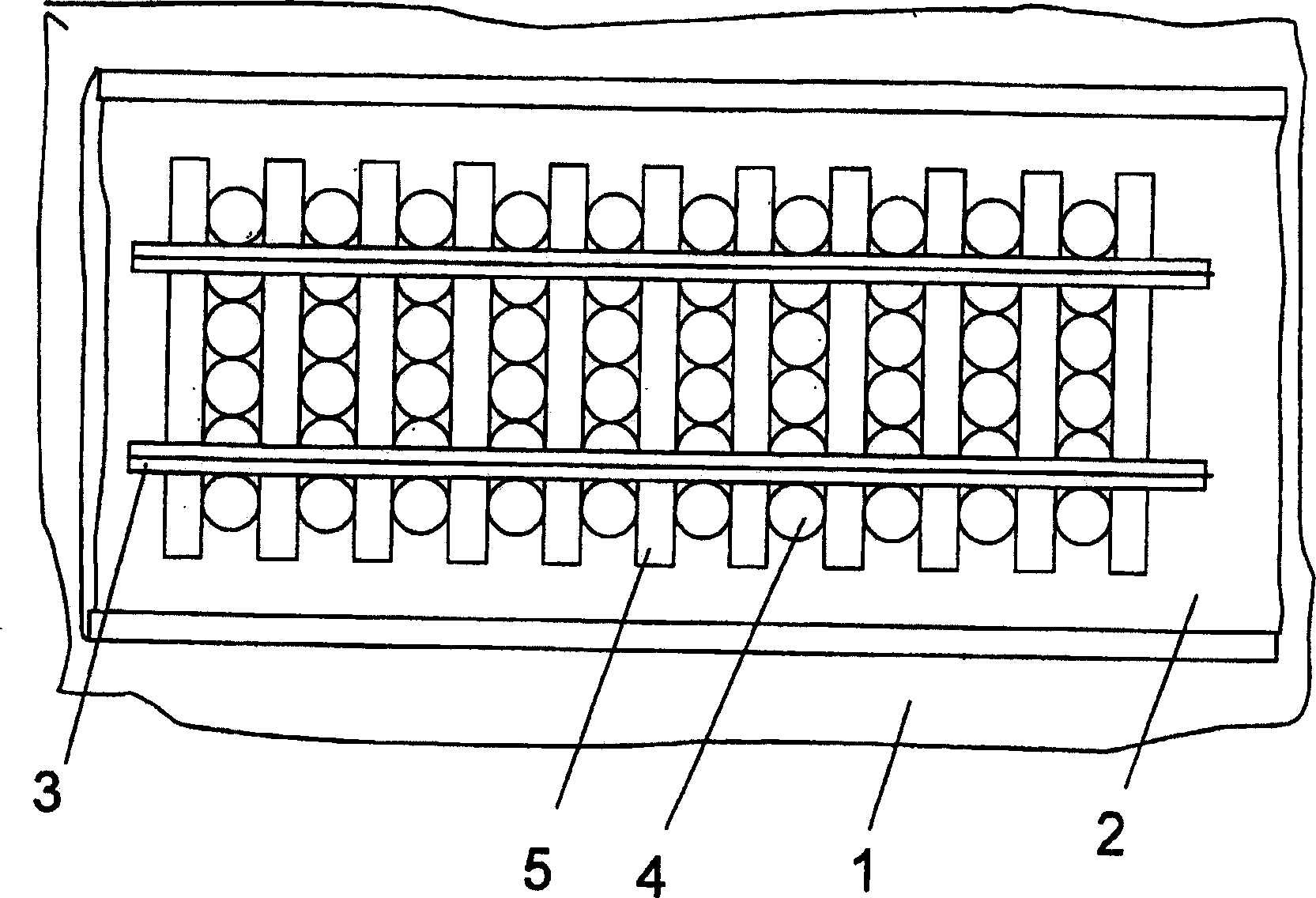

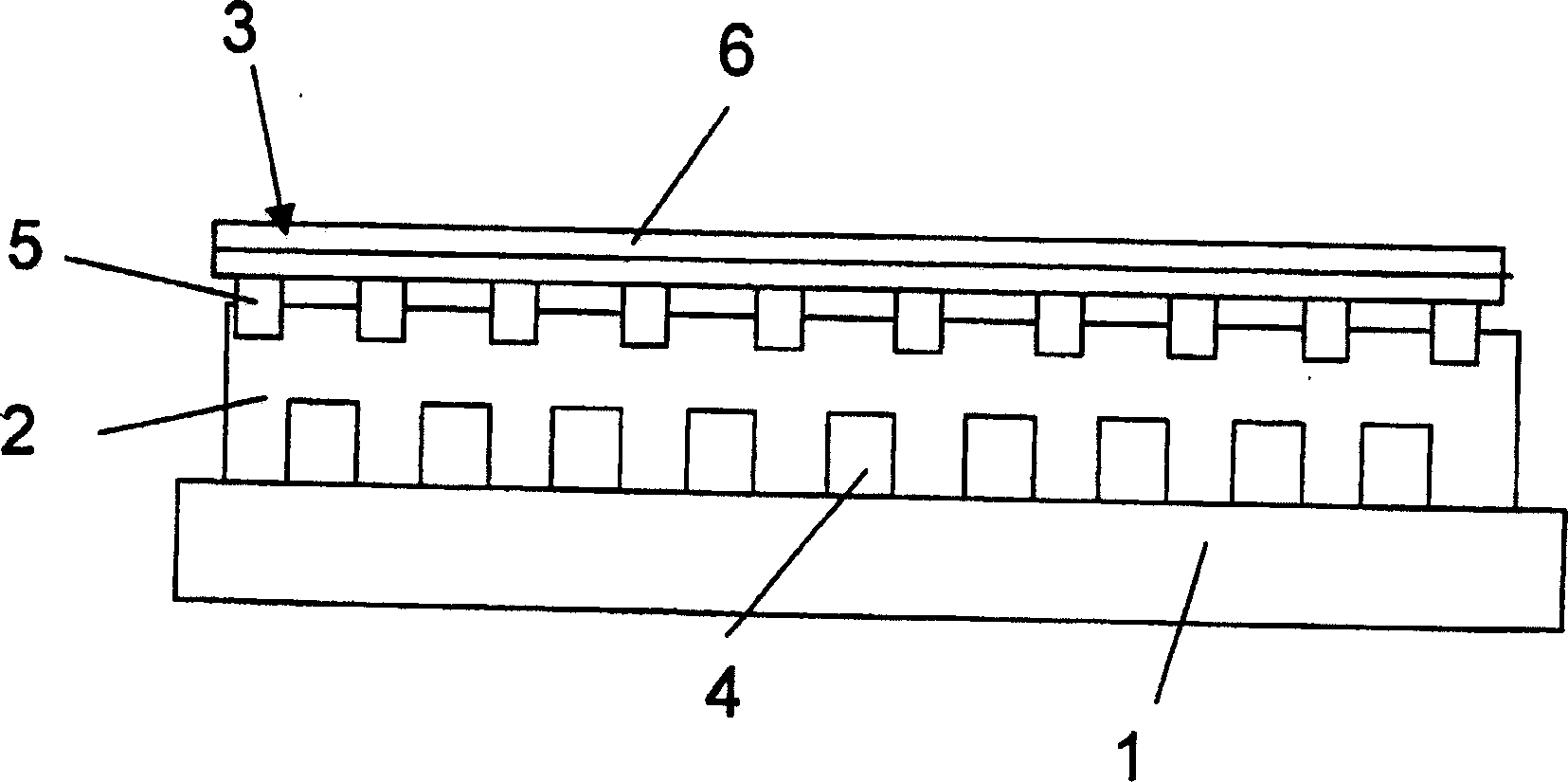

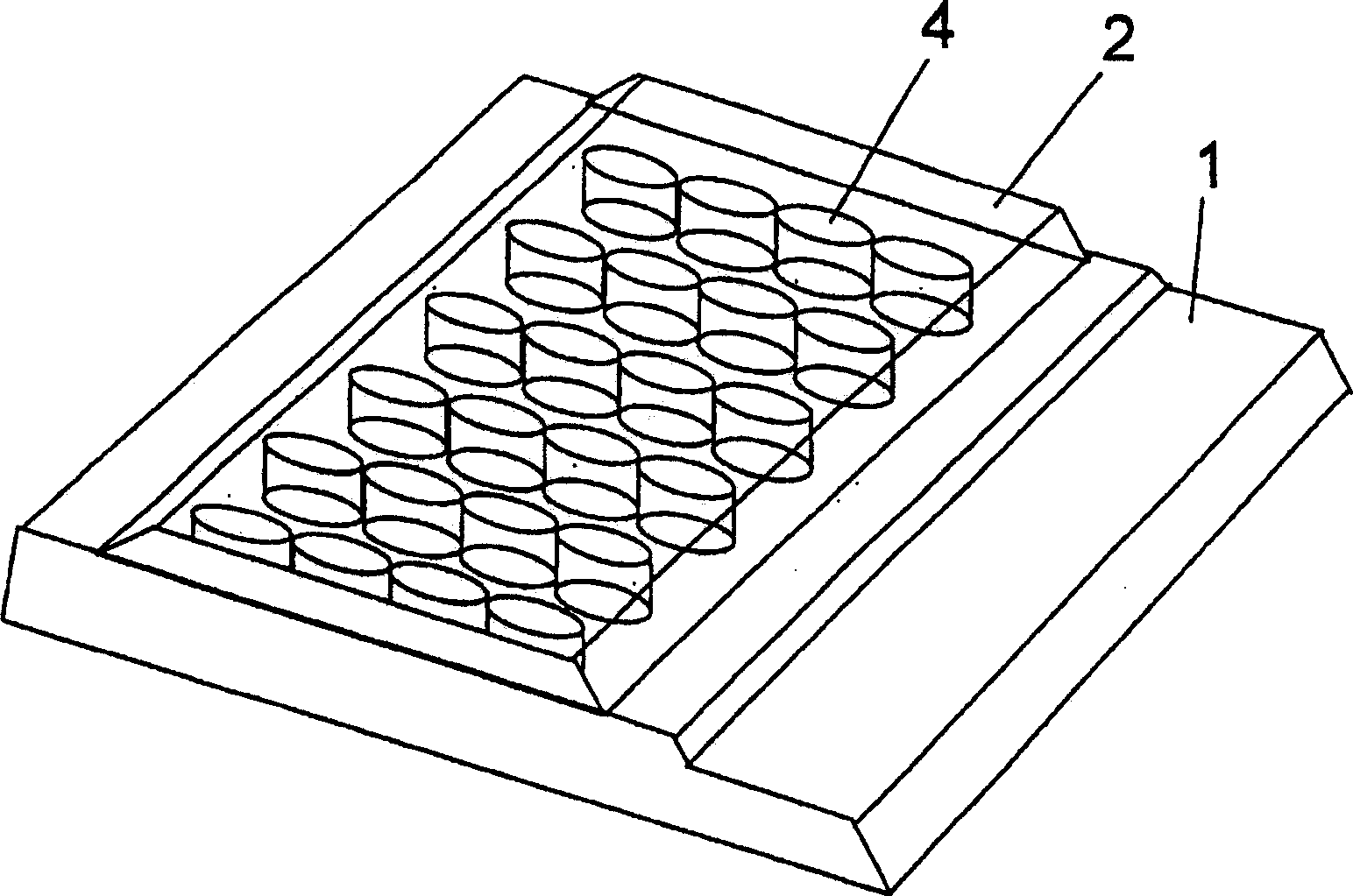

[0037] figure 1 A top view of the foundation 1 and the track grid 3 built on the gravel bed 2 is shown. The gravel ballast bed 2 is a substructure constituting a solid road bearing layer. To this end, in the crushed stone bed 2, a number of pillars 4 made of crushed stones and binding substances are added. The pillars 4 are arranged between the sleepers 5 and can be inserted into the gravel ballast bed 2 without continuous adjustment of the driving operation. For example, under pressure and after placing the pillars 4 in the gravel bed 2 with a grouting nozzle, the running operation can be resumed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com