Hollow mould for cast-in-situ concrete filling

A technology of hollow carcass and cast-in-place concrete, which is applied to the on-site preparation of building components, formwork/formwork/work frame, structural elements, etc., which can solve the problems of inconvenient assembly line production, low production efficiency, and inconvenient production. Achieve the effect of simple design, simple construction and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

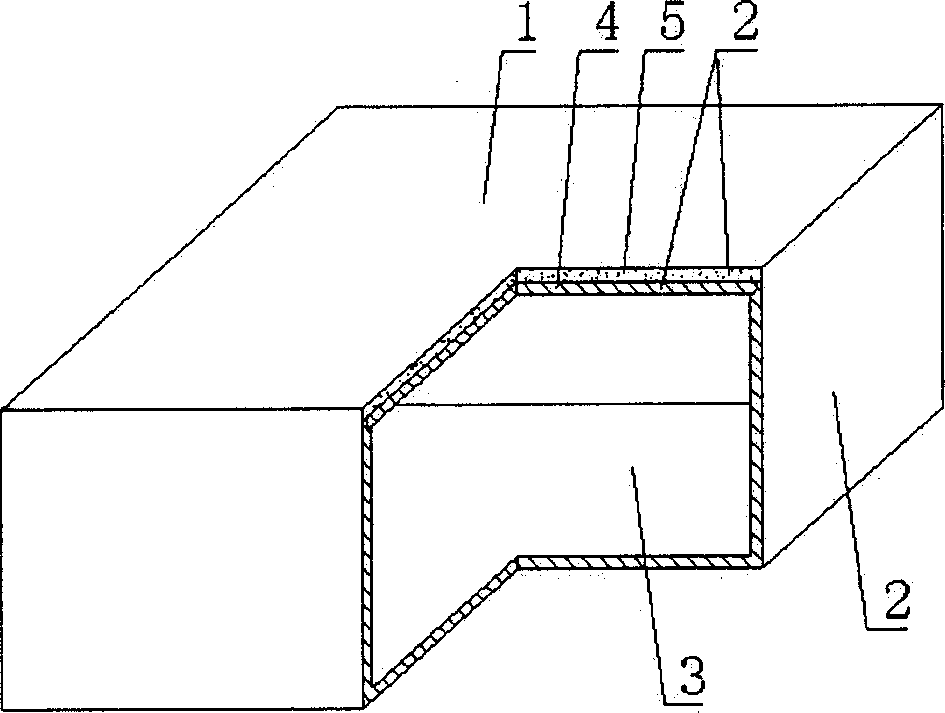

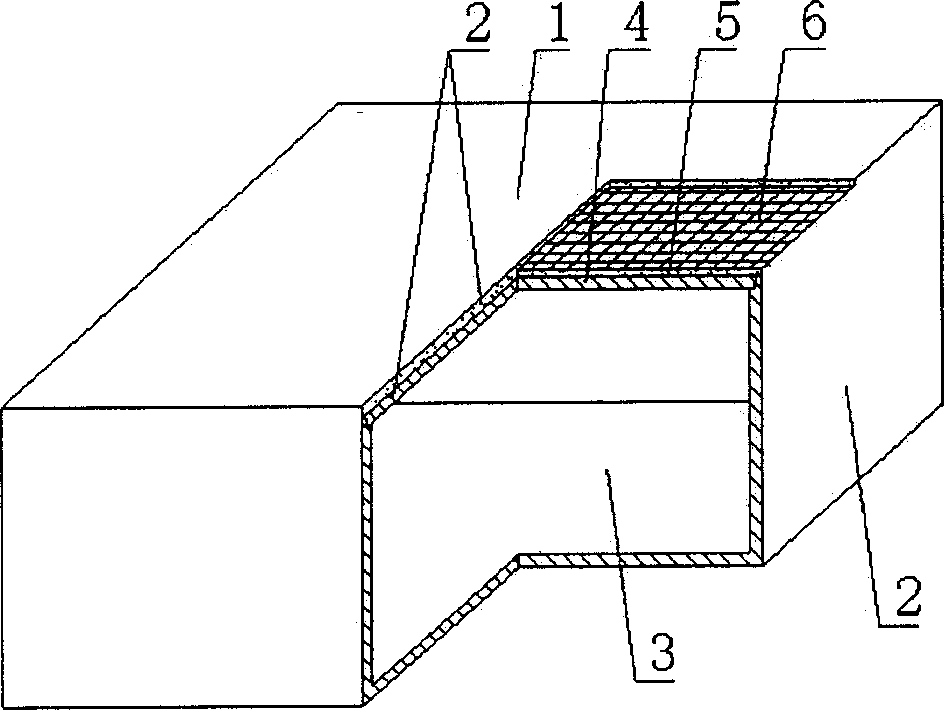

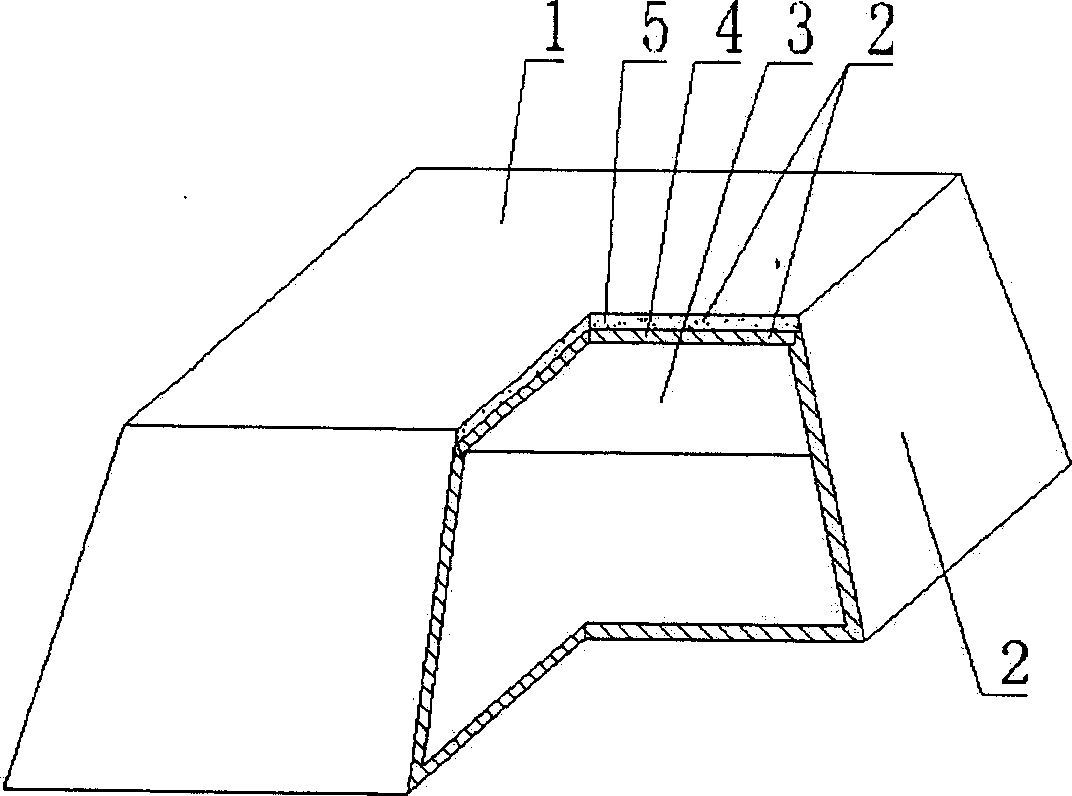

[0071] As shown in the accompanying drawings, the present invention includes a hollow carcass 1, which is formed by surrounding an outer wall 2 and has a cavity 3 inside, and is characterized in that at least one outer wall 2 of the hollow carcass 1 is prefabricated The board wall 4 and the slurry embryo body 5 are soft and hard laminated, cemented and hardened. In the accompanying drawings, 1 is the hollow carcass, 2 is the outer wall, 3 is the cavity, 4 is the prefabricated board wall, and 5 is the slurry body. In the following drawings, those with the same number have the same description. Such as figure 1 As shown, the hollow carcass 1 is formed by enclosing the outer wall 2, and there is a cavity 3 inside. The upper outer wall 2 of the hollow carcass 1 is a prefabricated board wall 4 and a slurry embryo body 5, which are soft and hard laminated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com