Carbon heater

A carbon heater and heater technology, applied in heating elements, ohmic resistance heating, heating element shape and other directions, can solve the problem of radiant energy not being emitted evenly, achieve the effect of firm carbon filament support structure and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

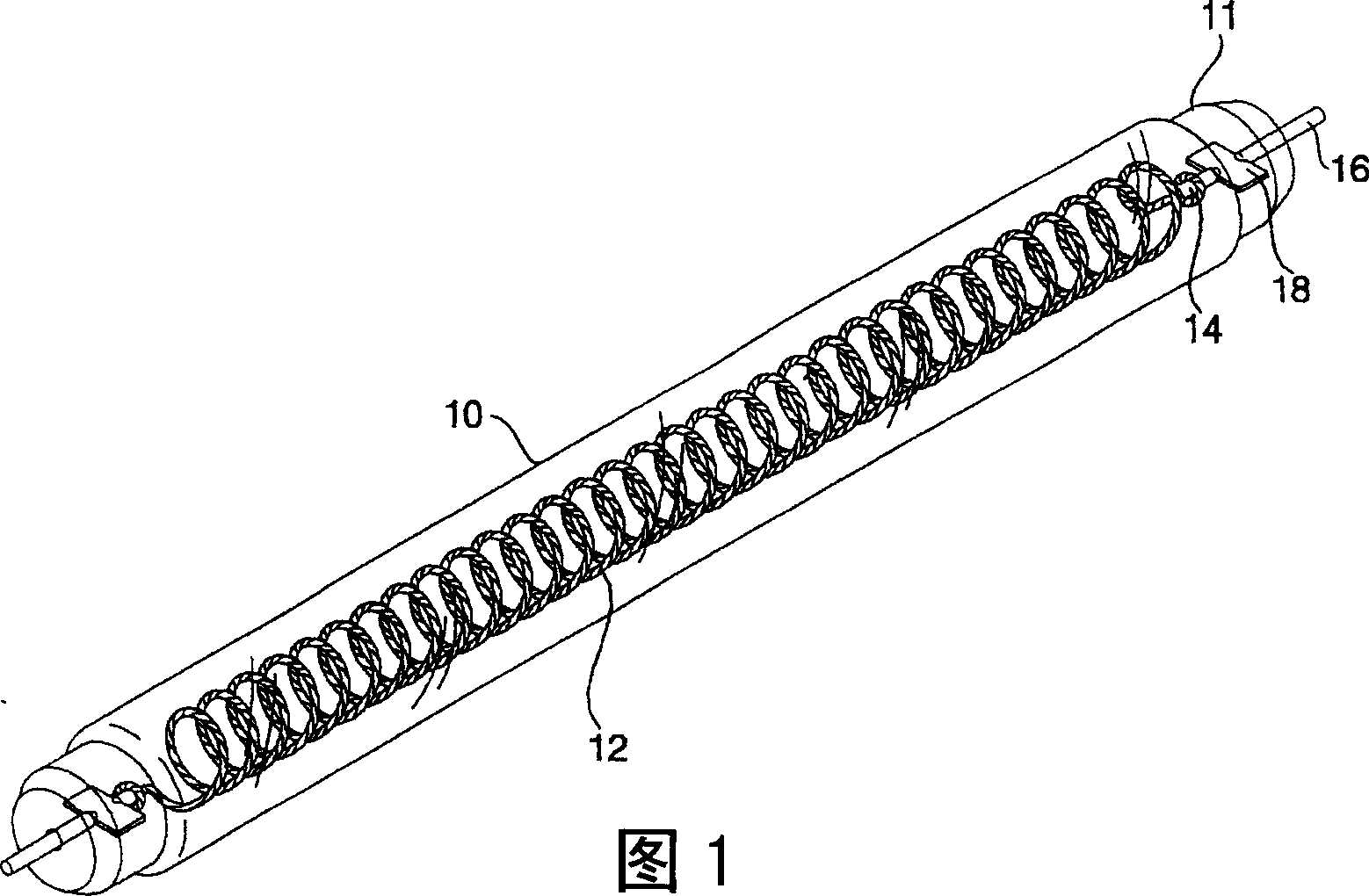

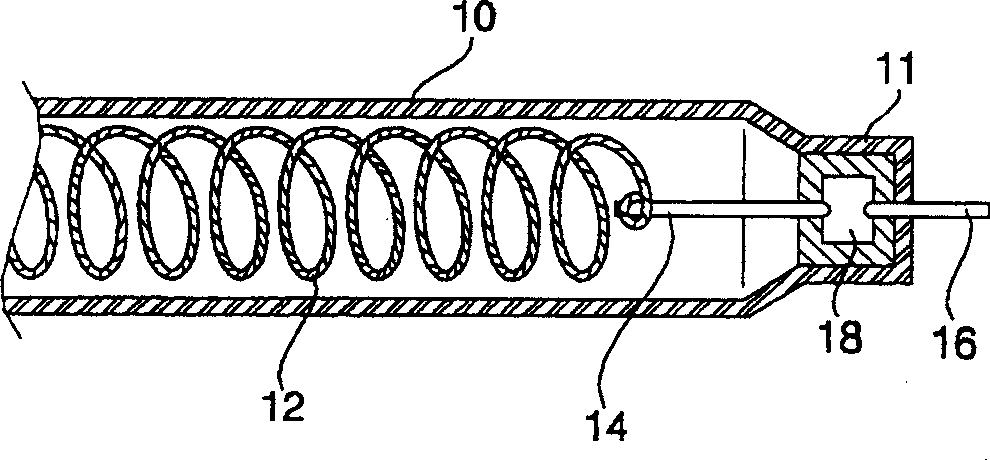

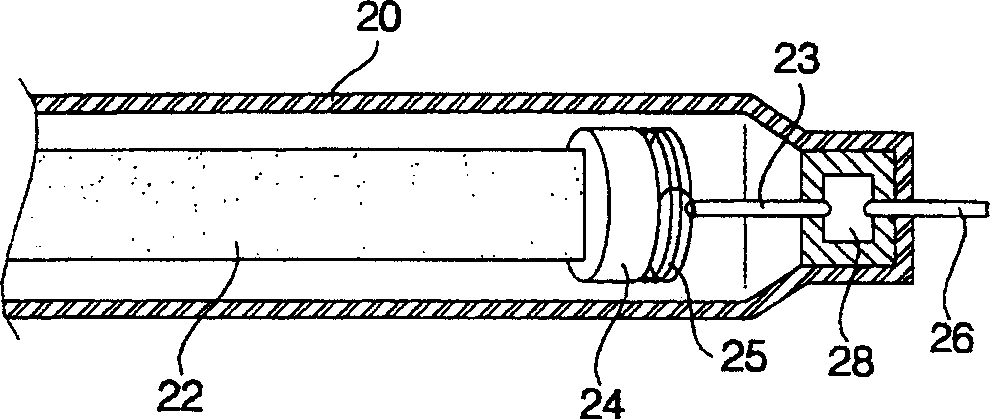

[0036] Now, some preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0037] Figure 4 is a longitudinal sectional view showing the main parts of the carbon heater according to the first preferred embodiment of the present invention.

[0038] Such as Figure 4 As shown, the carbon heater according to the first preferred embodiment of the present invention includes: a quartz tube 50, a tube seal 51 is formed at both ends of the quartz tube; Used as a heating element, the carbon wire 52 is formed into a twisted sheet shape; external electrodes 56 are respectively provided on the tube seals 51 of the quartz tube 50 and exposed to the outside of the quartz tube 50; metal wires 55 are respectively fixed by Metal pieces 58 to tube seal 51 at both ends of quartz tube 50 are connected to external electrodes 56; and connection conductors 54 are connected between both ends of carbon wire 52 and metal wire 55, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com