Continuous production device of slow-release or control-release fertilizer

A production device, slow and controlled release fertilizer technology, applied in the direction of fertilization device, fertilizer form, fertilizer mixture, etc., to achieve the effect of saving energy, improving uniformity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

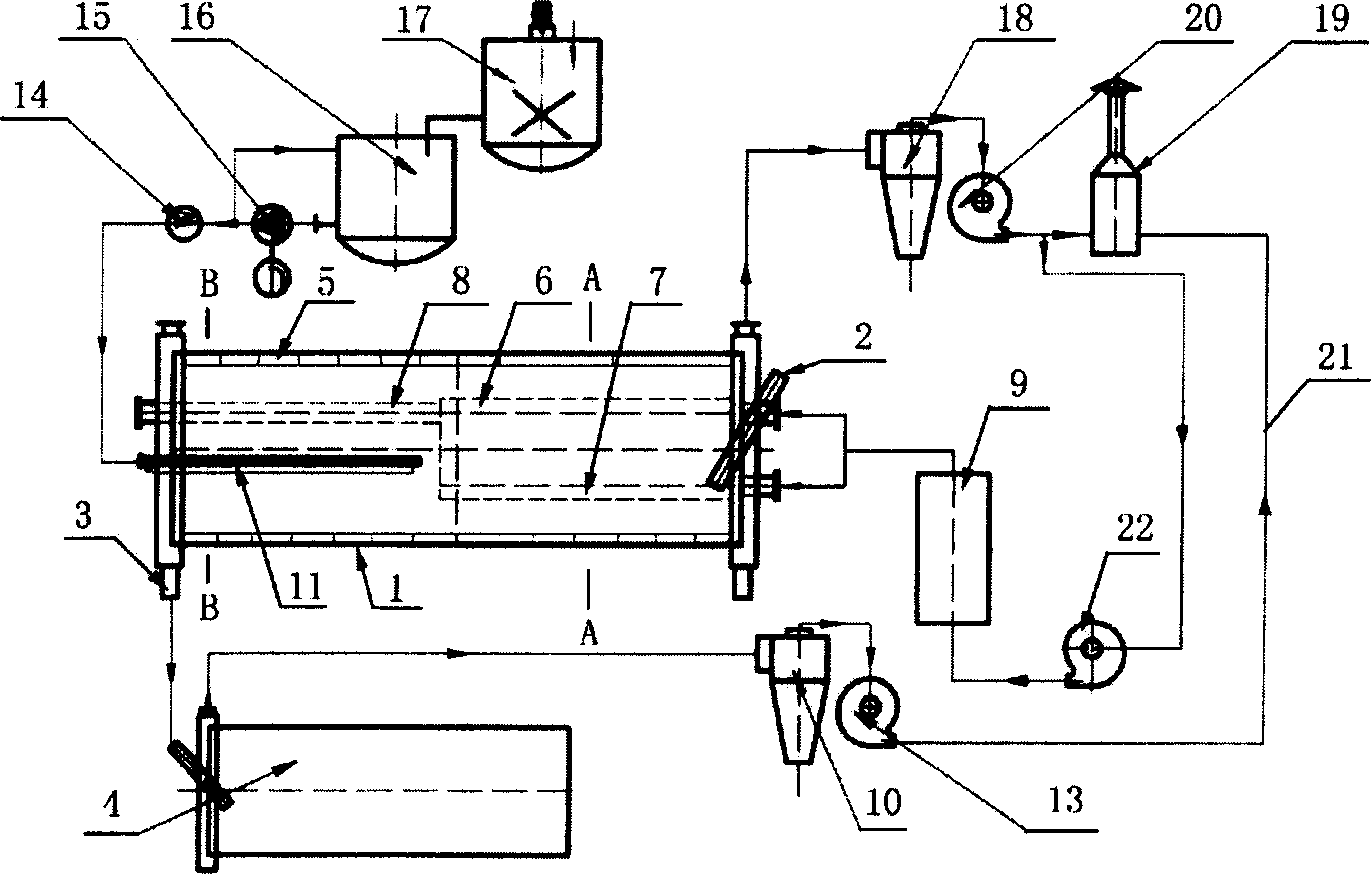

[0017] Examples see figure 1 , 2 , 3. This kind of continuous slow and controlled release fertilizer production device has a long cylindrical drum 1, with a feed port 2 at the front end of the drum, a discharge port 3 at the back end, and the discharge port is connected to a cooling mechanism 4. The hoisting hopper 5 is evenly arranged on the inner wall of the rotating drum. The lifting hopper 5 is shaped like a bucket of a waterwheel.

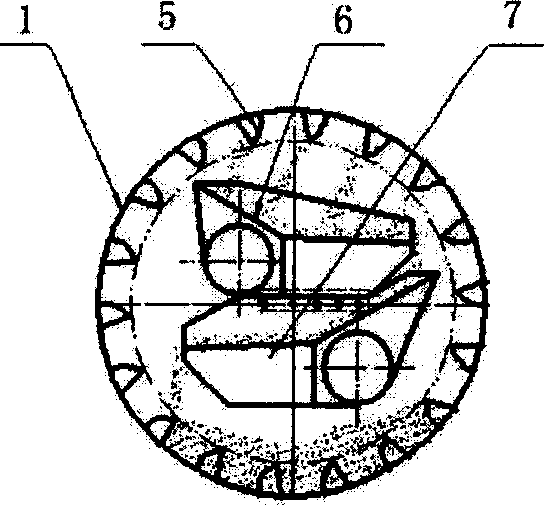

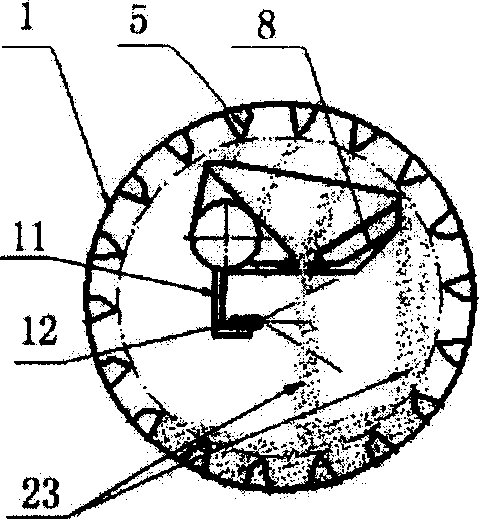

[0018] The upper preheating fluidized bed 6 and the lower preheating fluidized bed 7 are arranged in the axial direction in the front half of the rotating drum. The preheating fluidized bed is formed by fixing the bed body of the fluidized bed on the preheating tube. Pass heat medium. A funnel trough-shaped collecting bed 8 is arranged along the extension line of the upper fluidized bed in the second half of the rotating drum, and a spraying pipe 11 is arranged under the discharge port of the narrow and long funnel and parallel to the collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com