Cylinder block, cylinder head, and engine main body

A cylinder block and cylinder head technology, applied in the direction of engine components, machines/engines, variable displacement engines, etc., can solve the problems of easy deformation of holes, deformation of cylinder liners, obstruction of engine size and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

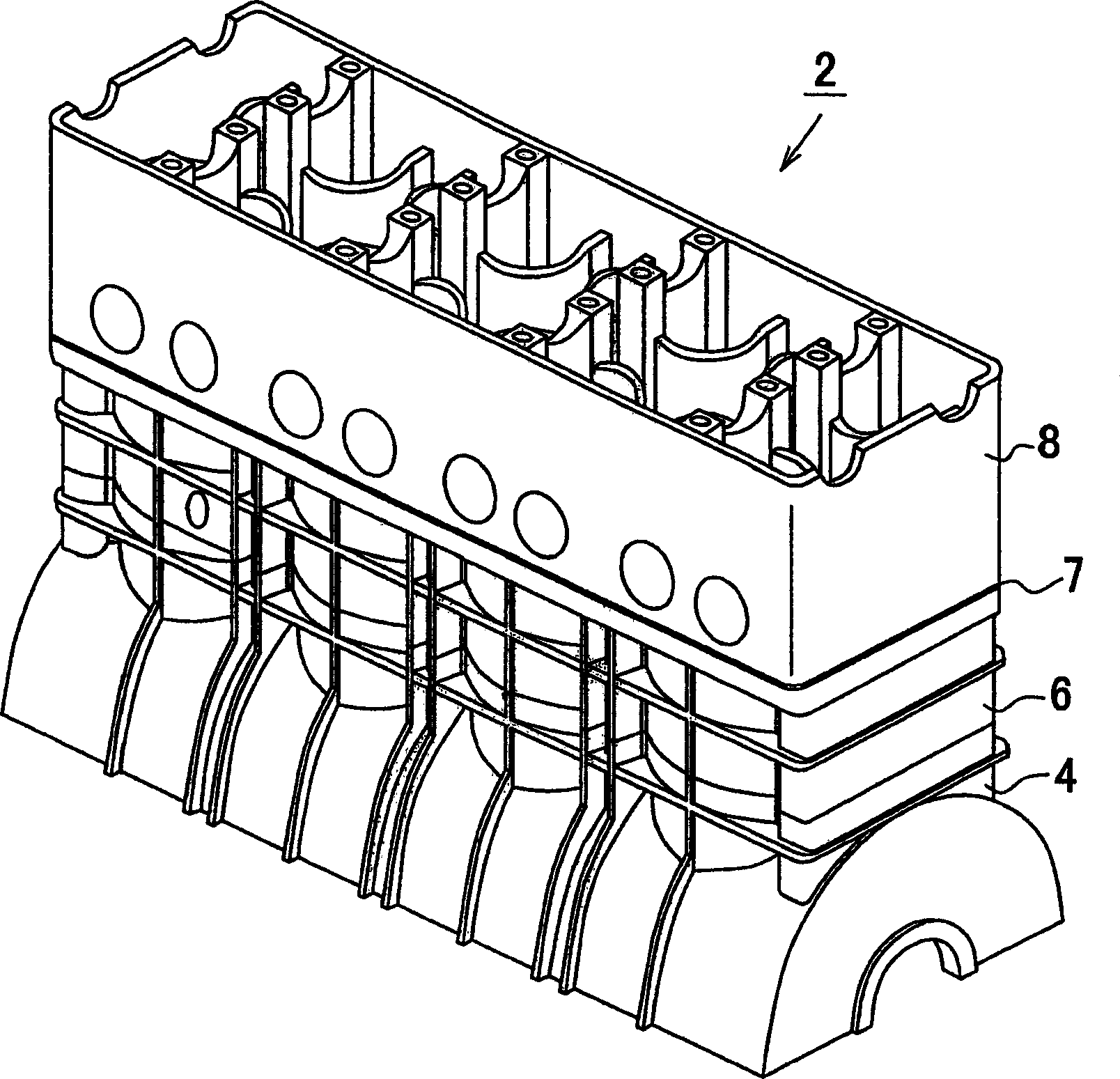

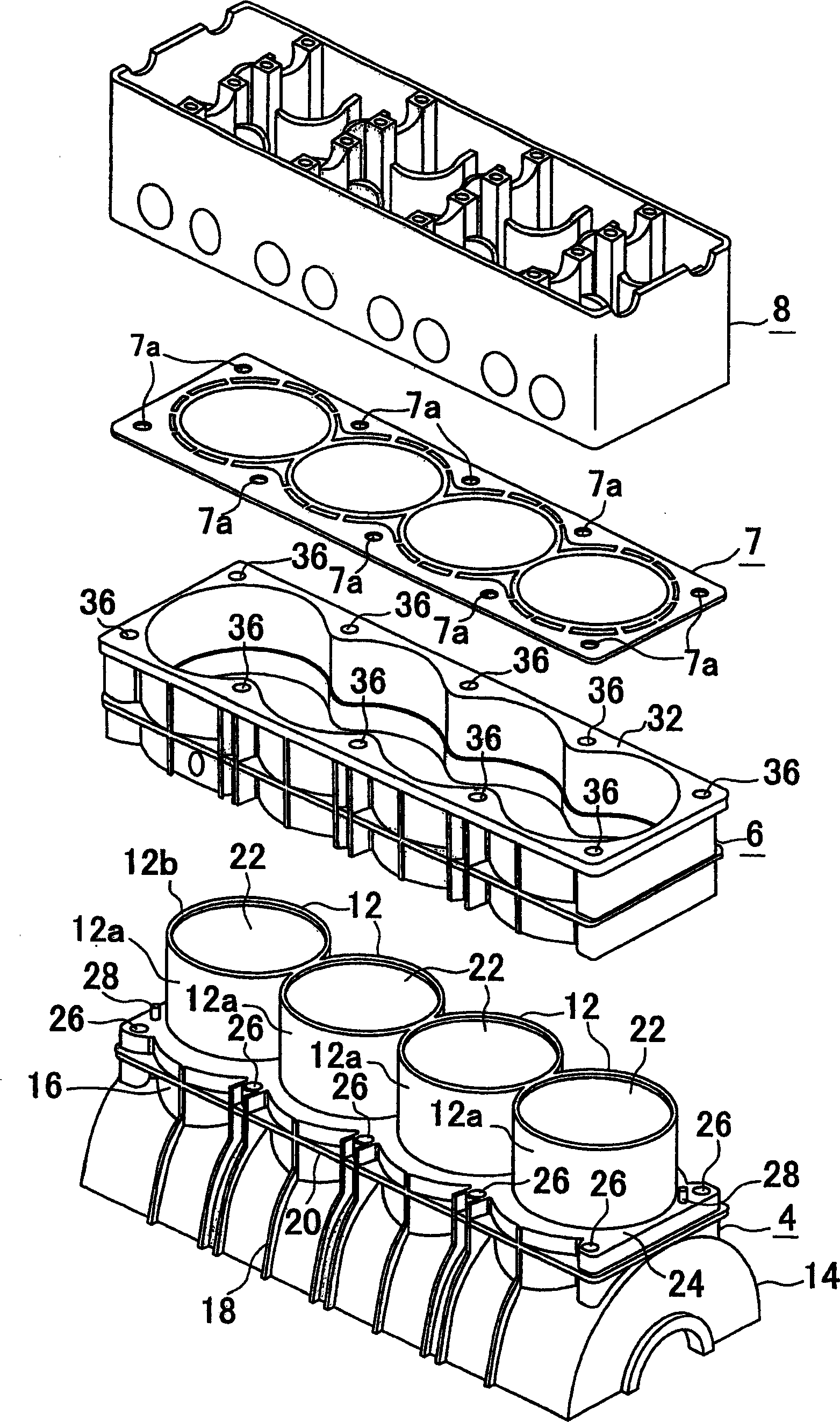

[0068] As the first exemplary embodiment of the present invention, figure 1 The perspective view shows the structure of the engine body 2 using the four-cylinder internal combustion engine of the present invention. This engine main body 2 is constructed by stacking the main body cylinder block 4, the outer cylinder block 6, the gasket (seal) 7 and the cylinder head 8, such as figure 2 As shown in the exploded perspective view.

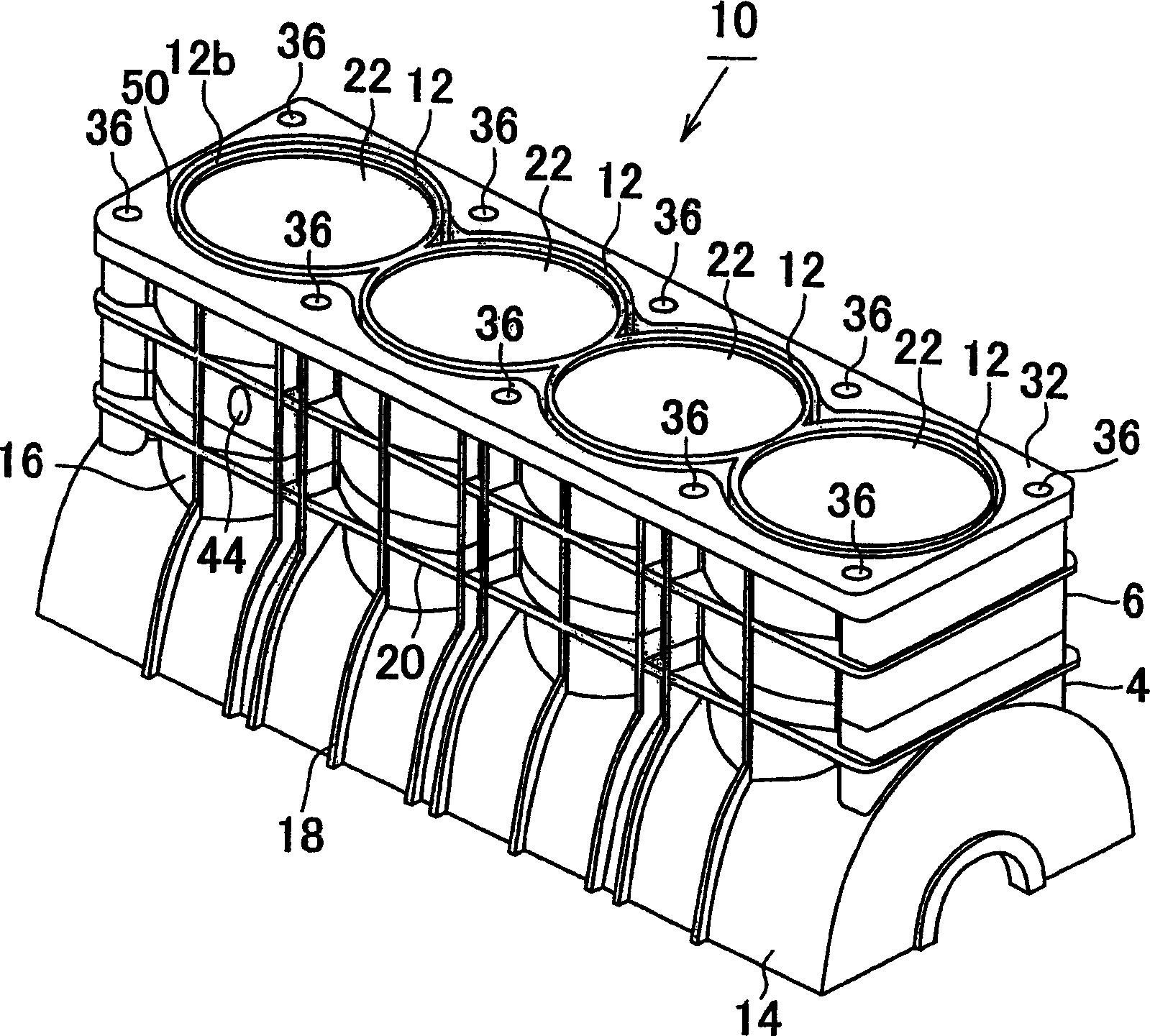

[0069] The main cylinder block 4 and the outer cylinder block 6 are assembled together, such as image 3 Perspective view and Figure 4 As shown in the top view, the cylinder block 10 is formed.

[0070] The main cylinder block 4 is integrally cast from aluminum alloy or magnesium alloy. The main body cylinder block 4 includes four cylindrical cylinders 12 formed at the top, a skirt 14 formed at the bottom, and an outer wall mounting part 16 formed between the cylinder 12 and the skirt 14. A plurality of ribs 18 and 20 are provided on the outer sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com