Laser energy meter

A laser energy meter and laser technology, which is applied in the direction of using electric radiation detectors for photometry, etc., can solve the problems of unusable and difficult to obtain large-area detectors, avoiding local damage, feasible design technology, and uniform energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention provides a novel laser energy meter to overcome the shortcomings of the prior art.

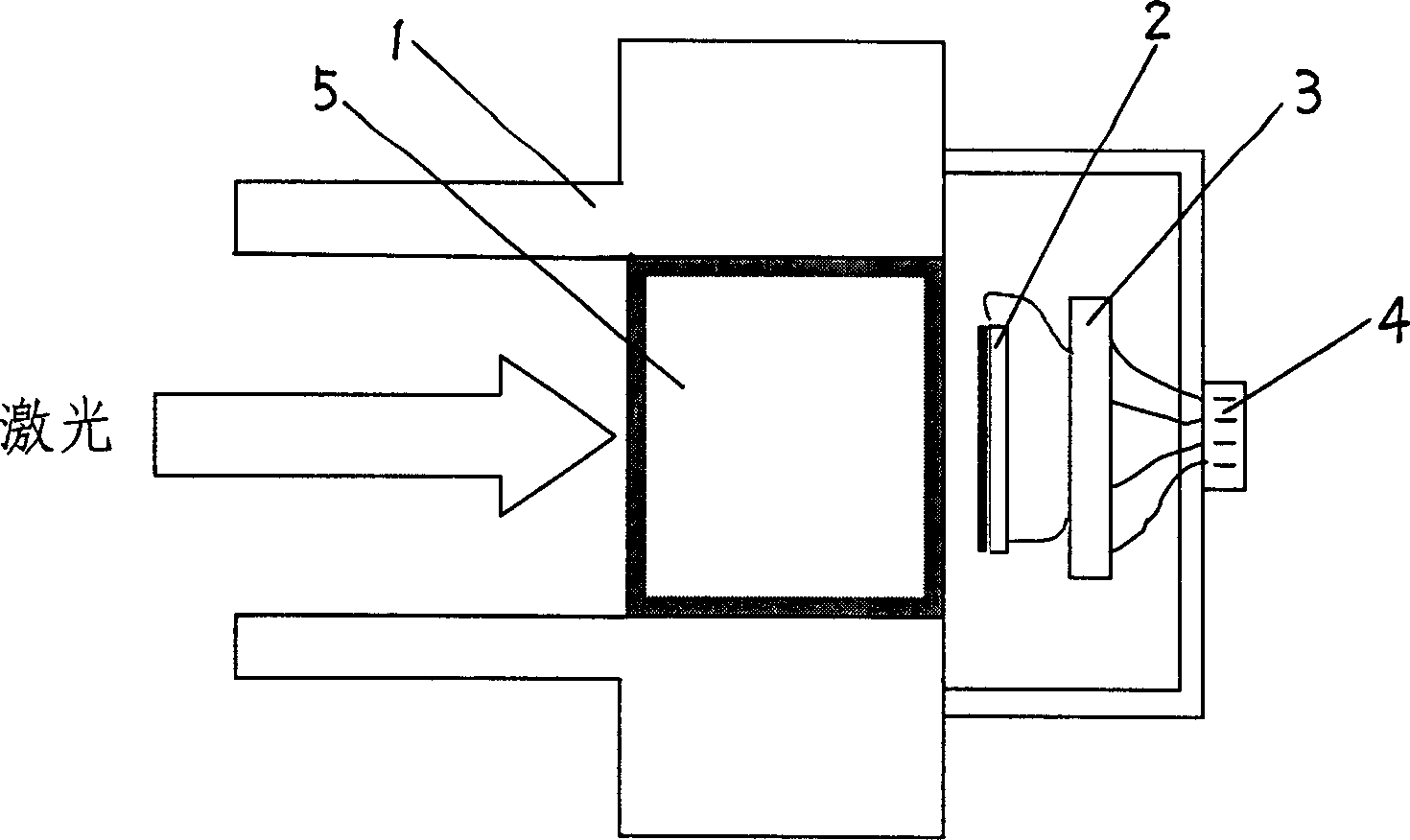

[0013] The laser energy meter structure of the present invention sees figure 1 , the laser energy meter has a tubular metal housing 1, in the rear part of the housing 1, a detector 2, an amplifier 3 and a signal output unit 4 are installed in sequence, and, in the front part of the housing 1 (referring to the detector 2) at an appropriate distance, a ceramic hollow cavity 5 is installed.

[0014] The ceramic hollow cavity 5 is a closed hollow cylinder, the axial direction of the cylinder is parallel to the direction in which the laser enters the casing, that is, the front surface of the ceramic hollow cavity 5 receives the laser light entering from the outside of the casing 1; and the ceramic hollow cavity 5. The side of the cylinder is closely connected with the inner wall of the metal shell 1.

[0015] In the present invention, the detector 2 uses a lead zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com