Process for producing low-heat beer

A production process and low-calorie technology, applied in the field of biochemistry, to achieve the effects of low alcohol content, increased extract concentration, and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

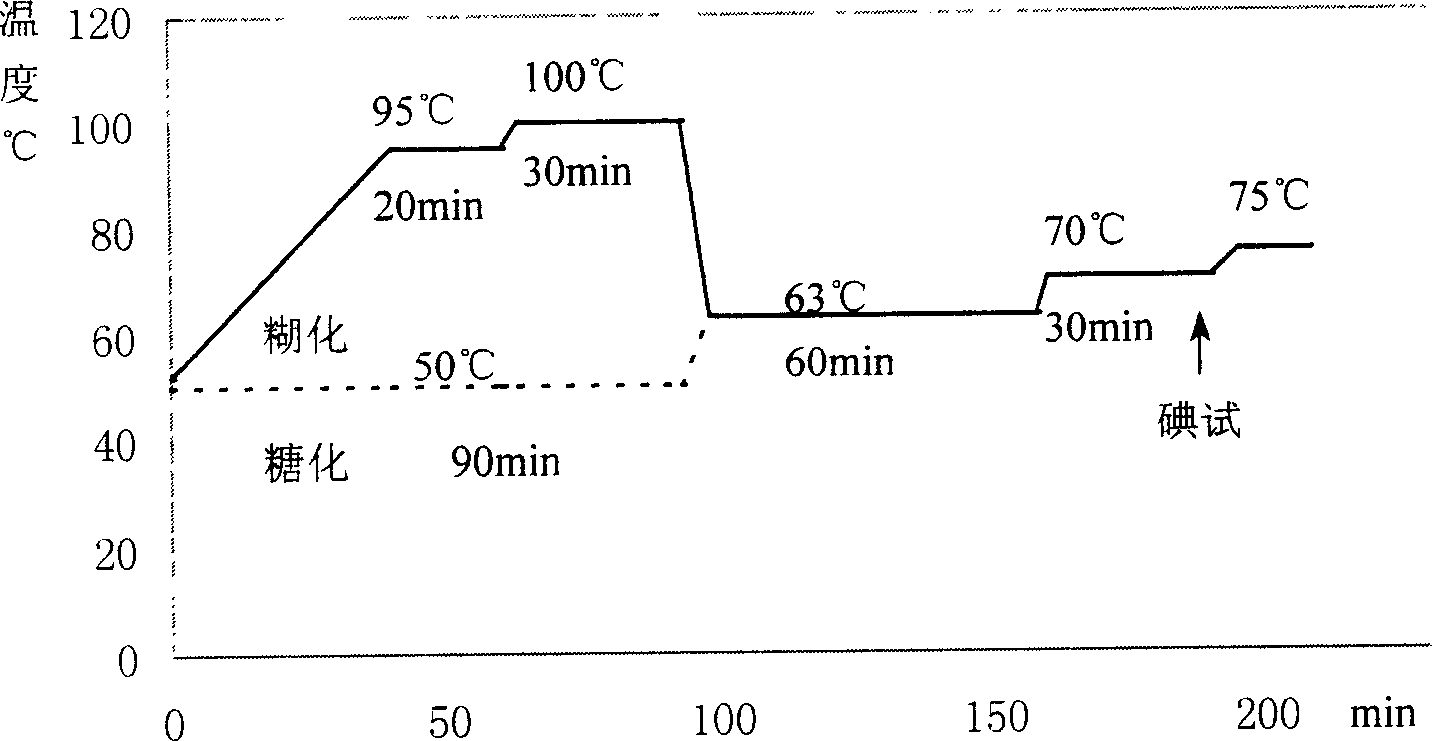

[0023] After 70kg of rice is crushed, enter the gelatinization pot, add 450L of brewing water at 52°C, add high-temperature-resistant amylase, adjust the pH value to 6.5 with lactic acid, heat up to 95°C and keep it for 20 minutes, then raise the temperature to 100°C and keep it for 30 minutes. During saccharification, put 120kg of crushed malt into it and mix it with 500L of brewing water, adjust the pH value to 5.4 with lactic acid, rest the protein at 50°C for 90min, and mash to 63°C for 60min. Go to 70°C and keep warm for 30min. After the iodine test is completed, the saccharification is completed, and the temperature is raised to 75°C. Then after filtering, add washing water to wash the grains, add brewing water, control the boiling for 60 minutes, add hops in two times, the first time is to add 2.8g of bitter flowers 40 minutes after the initial boiling, and the second time is to add 10 minutes before the end of boiling 1.2g of fragrant flowers, and add 10kg of white gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com