Anticipatory high frequency noise compensation in a distributed process control system

A control system and process control network technology, applied in the field of distributed process control network, can solve the problems of high price, short round-trip communication time, and unnecessary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

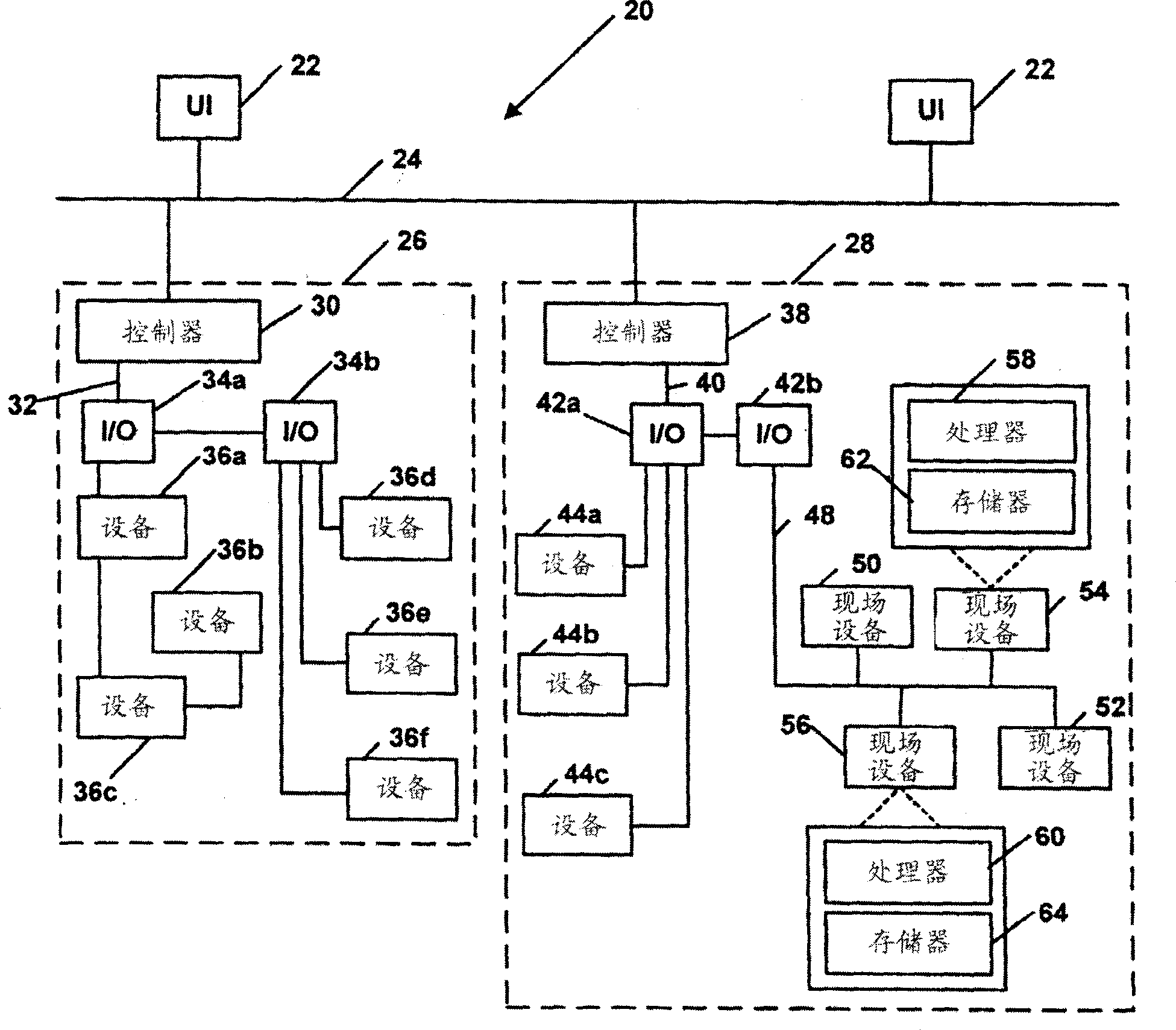

[0014] figure 2 A distributed control network 20 (DCN) is illustrated comprising two user interfaces (UI) 22 communicatively connected to a physical communication network 24, which may be Ethernet or any other desired communication network. DCN 20 further includes subnetwork 26 and subnetwork 28, either or both of which may use 、PROFIBUS and the underlying FIELDBUS protocol, such as any proprietary or open source communication protocol. figure 2 The sub-network 26 illustrated in includes a controller 30 , which may be a personal computer, programmable logic controller, stand-alone processor, or other device suitable for storing and executing process control programs and communicating with the UI 22 . Controller 30 is communicatively coupled to a pair of input / output (I / O) devices 34a and 34b through a local physical network 32, which may be a proprietary or open source backplane. The I / O device 34a is, for example, communication on a bus or ring structure related to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com