Catalyst flow meter

A catalyst and mass technology, applied in indirect mass flow meters, mass flow measurement devices, measuring flow/mass flow, etc., can solve problems such as expensive and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

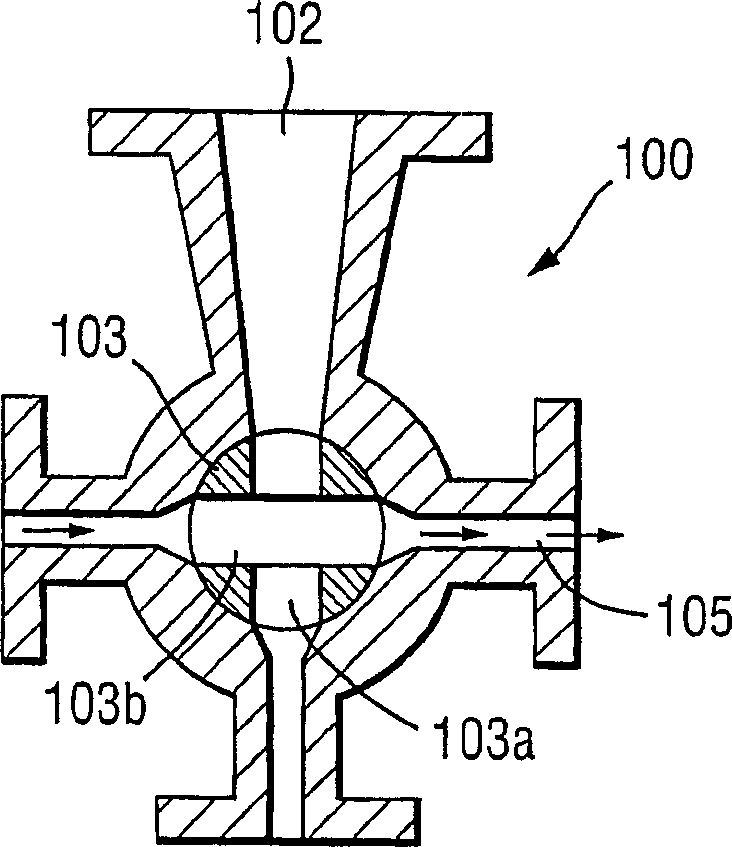

[0079] As mentioned above, figure 1A standard catalyst feeder 100 is shown for feeding a plug of catalyst to the reactor. The feeder 100 comprises a circular valve 103 comprising two disconnected channels 103a, 103b arranged perpendicular to each other. A valve 103 is provided at the connection between the catalyst canister and the channel 105 leading to the reactor. Valve 103 is rotated so that channel 103a is filled with catalyst. The valve is then turned 90° so that the catalyst can be flushed towards the reactor by the flow of diluent along channel 105 . Meanwhile, the second channel 103b is in line with the catalyst tank and is supplied with catalyst. In this way, a fixed amount of catalyst can be continuously supplied to the reactor.

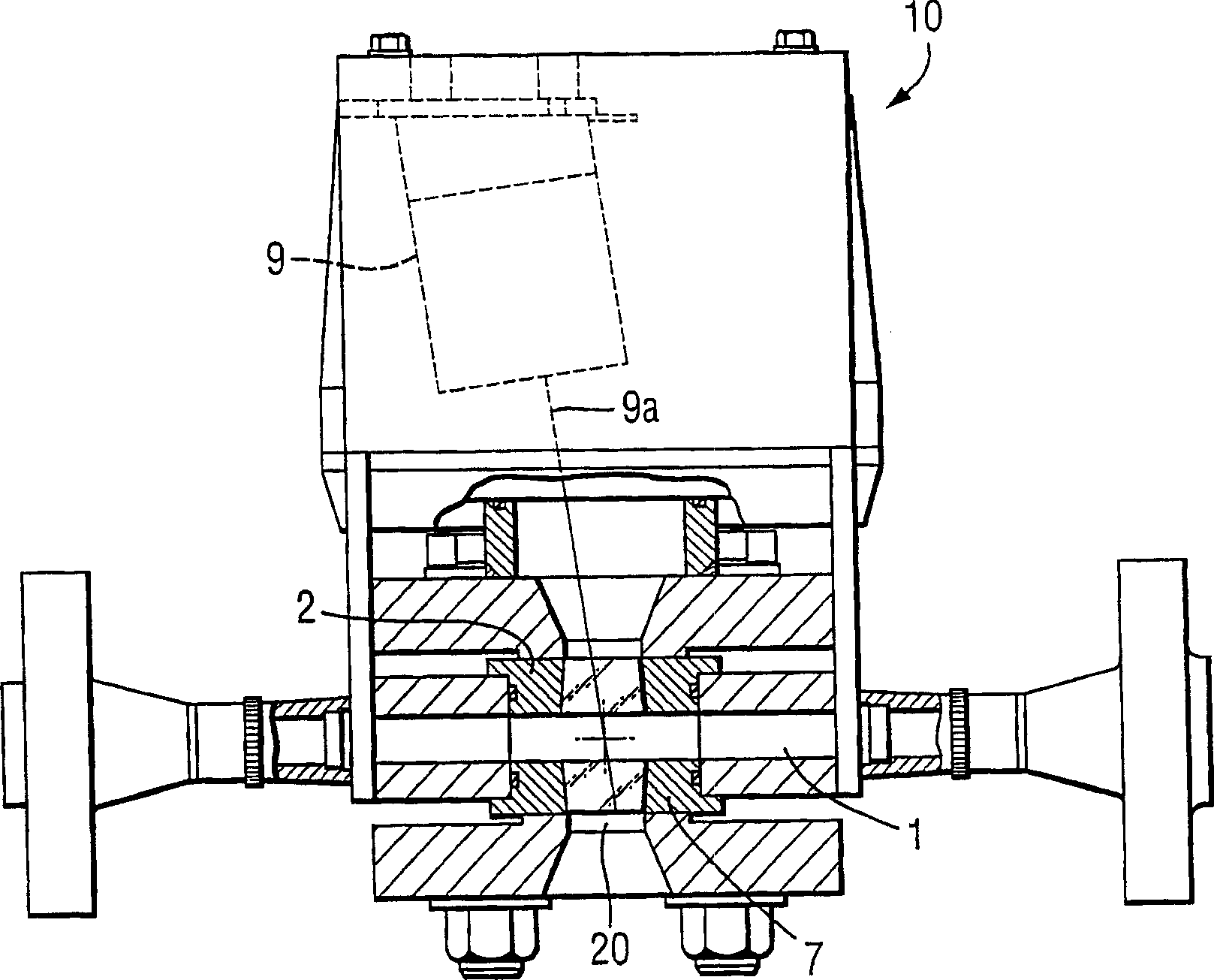

[0080] Light intensity detector 10 of the present invention (see figure 2 ) is arranged downstream of the feeder 100 along the channel 105. The device is based on a laser 9 which passes a beam 9 a through the sight glass 2 , the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com