Method and device for recognizing leaks

A technology of internal leakage and gas leakage, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve problems such as pipeline leakage detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

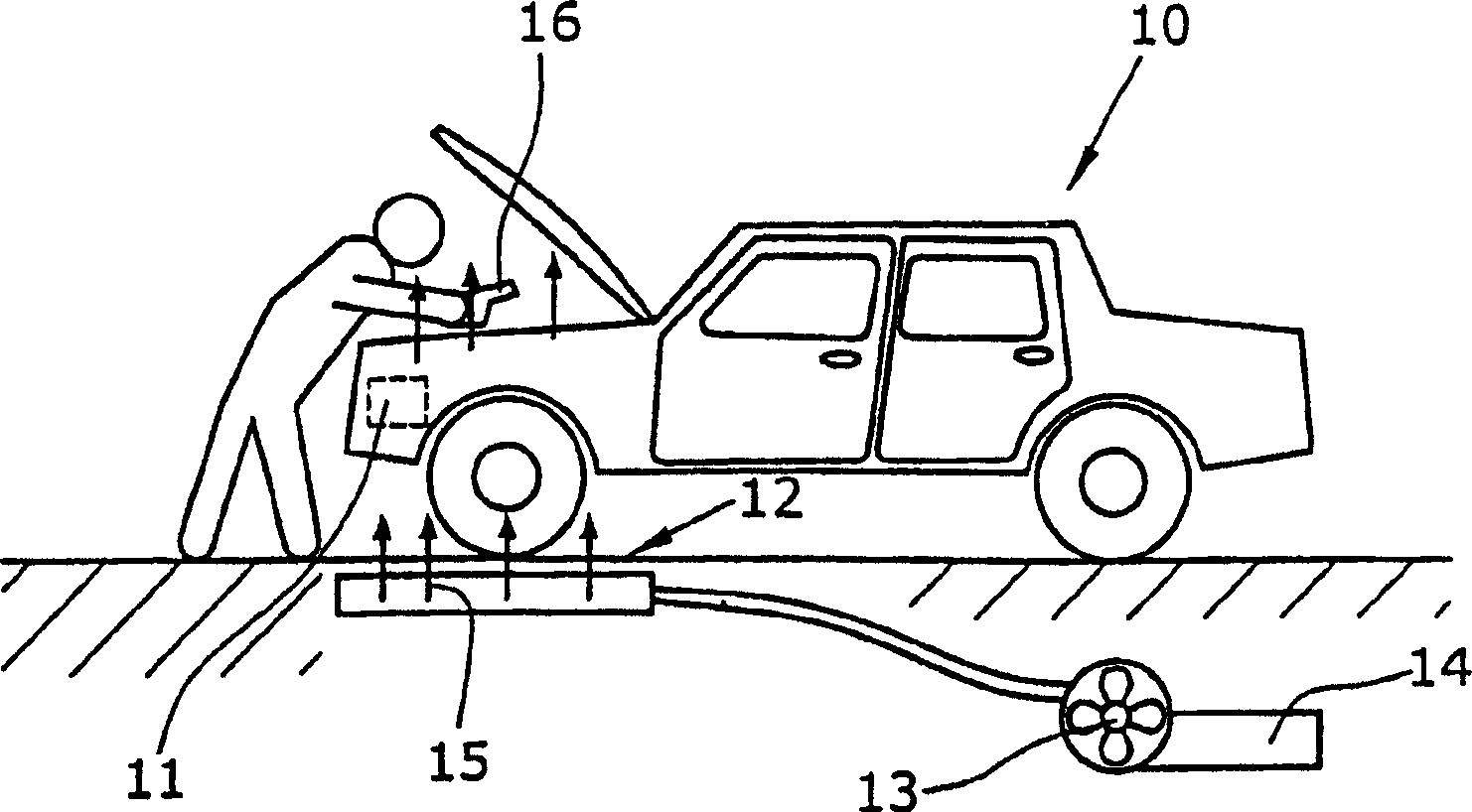

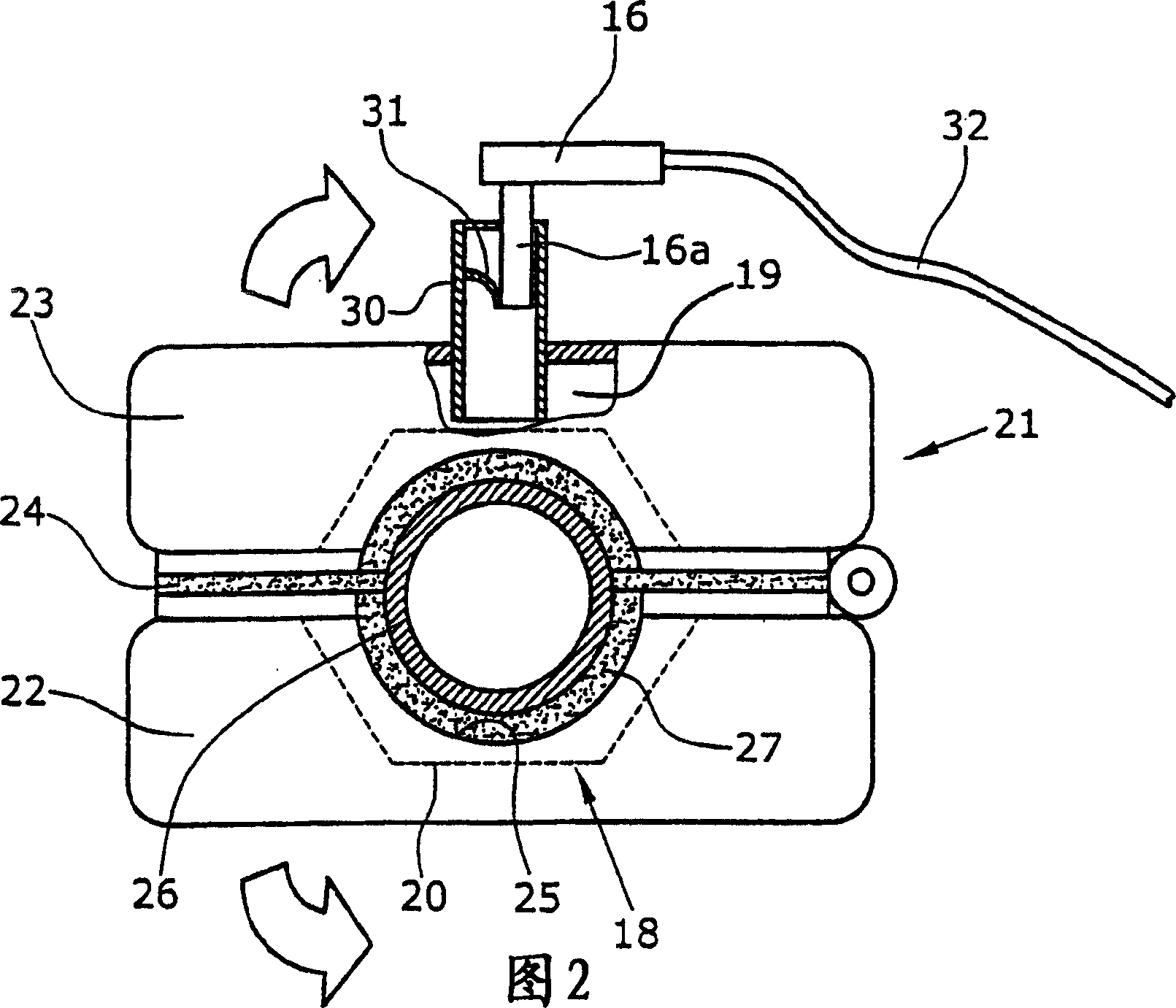

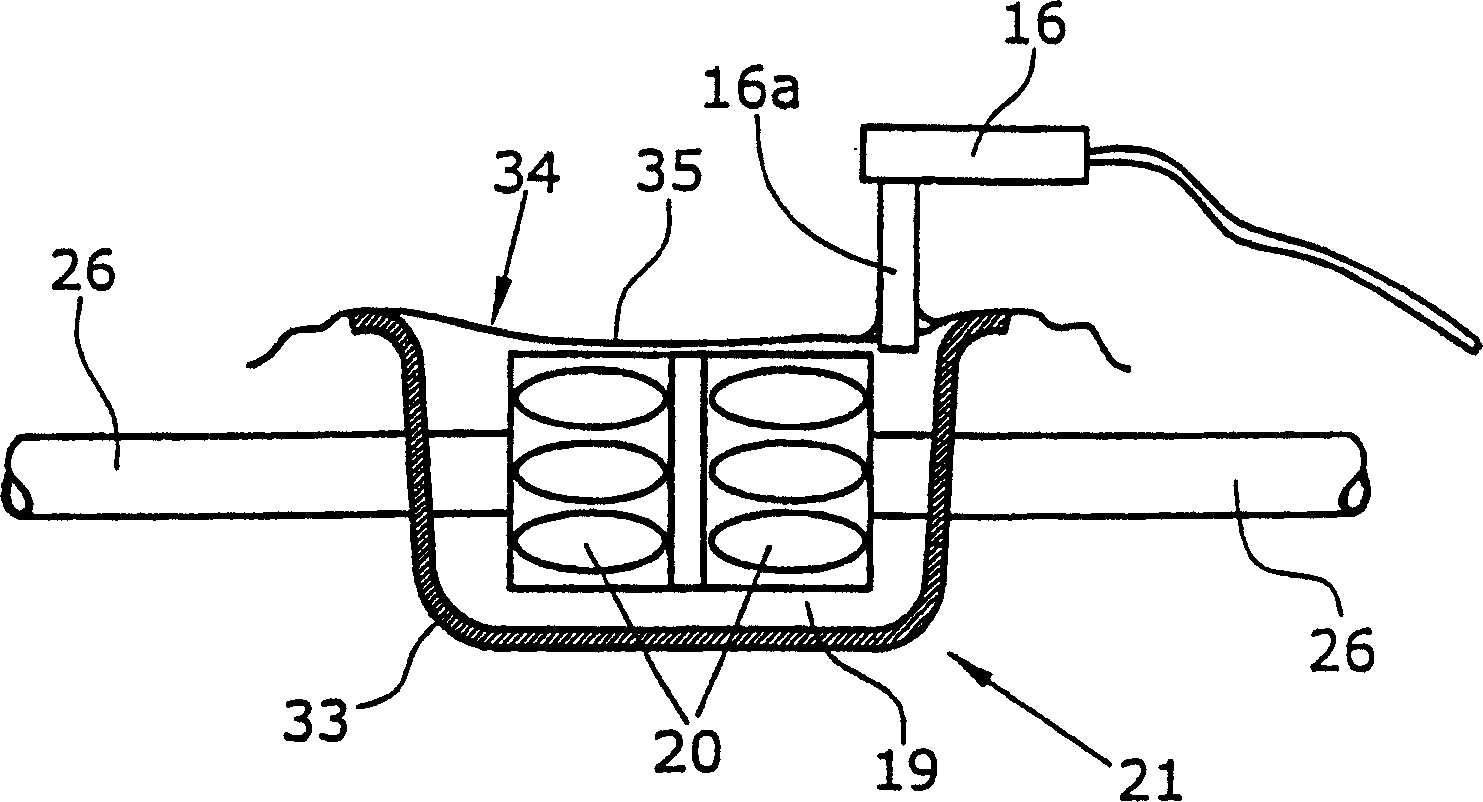

[0018] figure 1 The car is shown including its air conditioner assembly 11 in its engine compartment. The air conditioner has a coolant circuit that is required to be airtight. For gas leak detection, the air conditioner assembly 11 is arranged on a blowing device 12 connected to a fan 13 . The fan 13 draws in fresh air or another gas which does not contain the leakage gas to be detected via the inlet 14 . Fresh air contains concentrations of gases that can be used as leak gases (eg argon, carbon dioxide, helium). A gas flow 15 rises from said blowing means 12 and flows through the assembly 11 . Thereby, a defined environment is created in which leaking gas can be detected, ie the location of the detected gas, can be detected with the leak detection head 16 above the assembly 11 to detect the gas flow through the assembly 11 . The leak detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com