Compressor

A compressor and compression mechanism technology, applied in the field of compressors, can solve problems such as compressor failure, high-pressure pipeline vibration, and abnormal noises, and achieve the effects of preventing abnormal noises and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

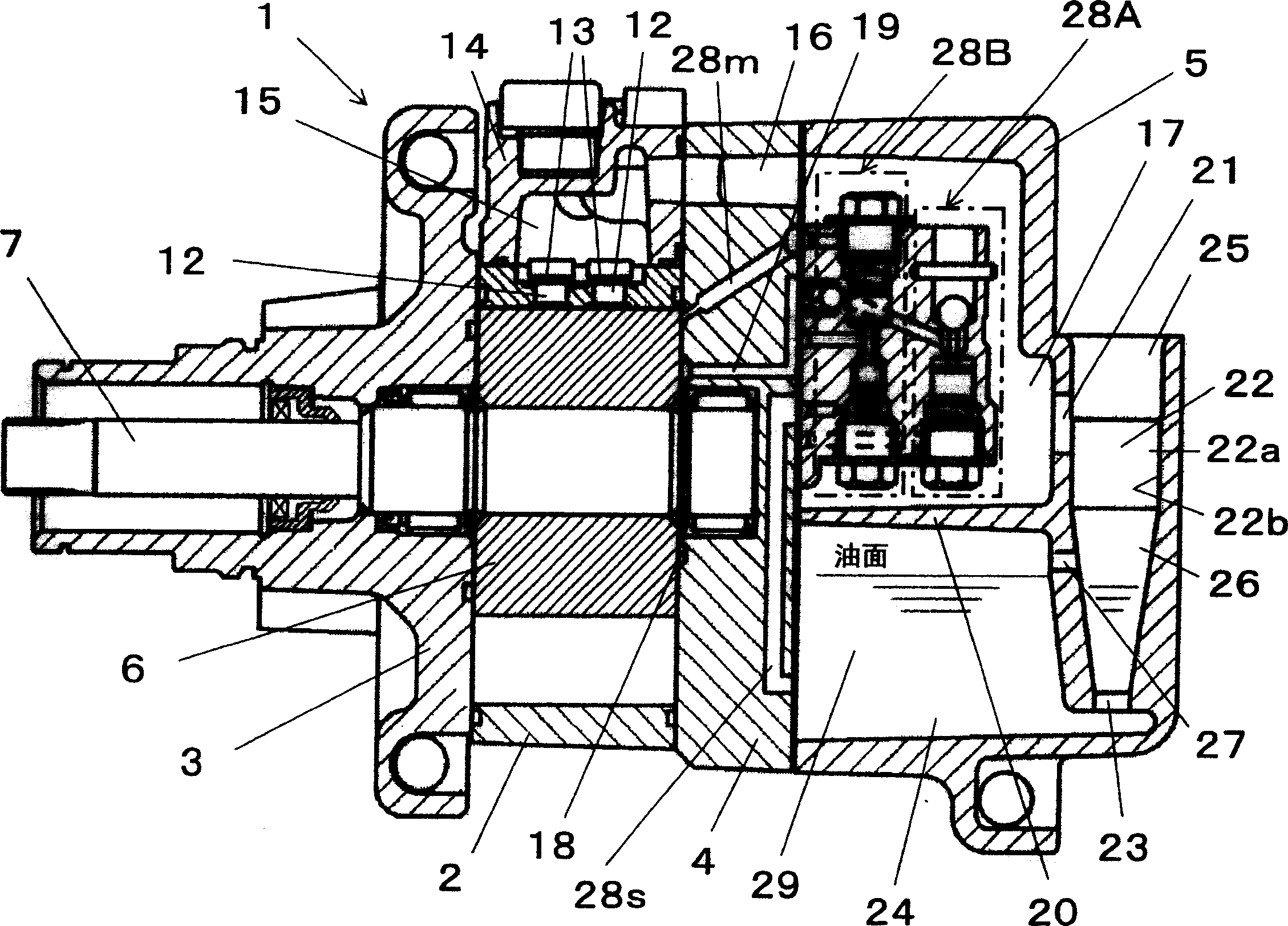

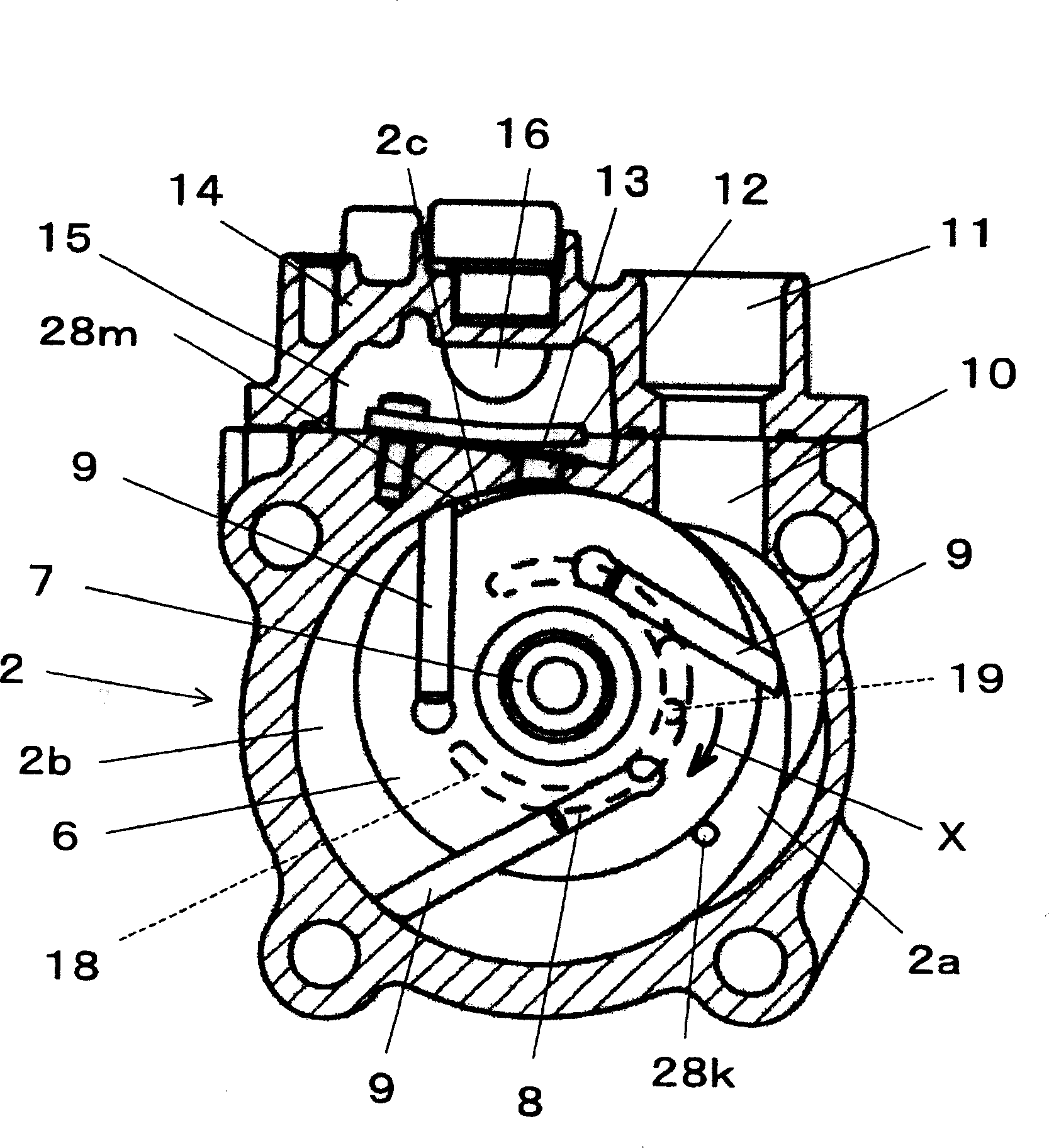

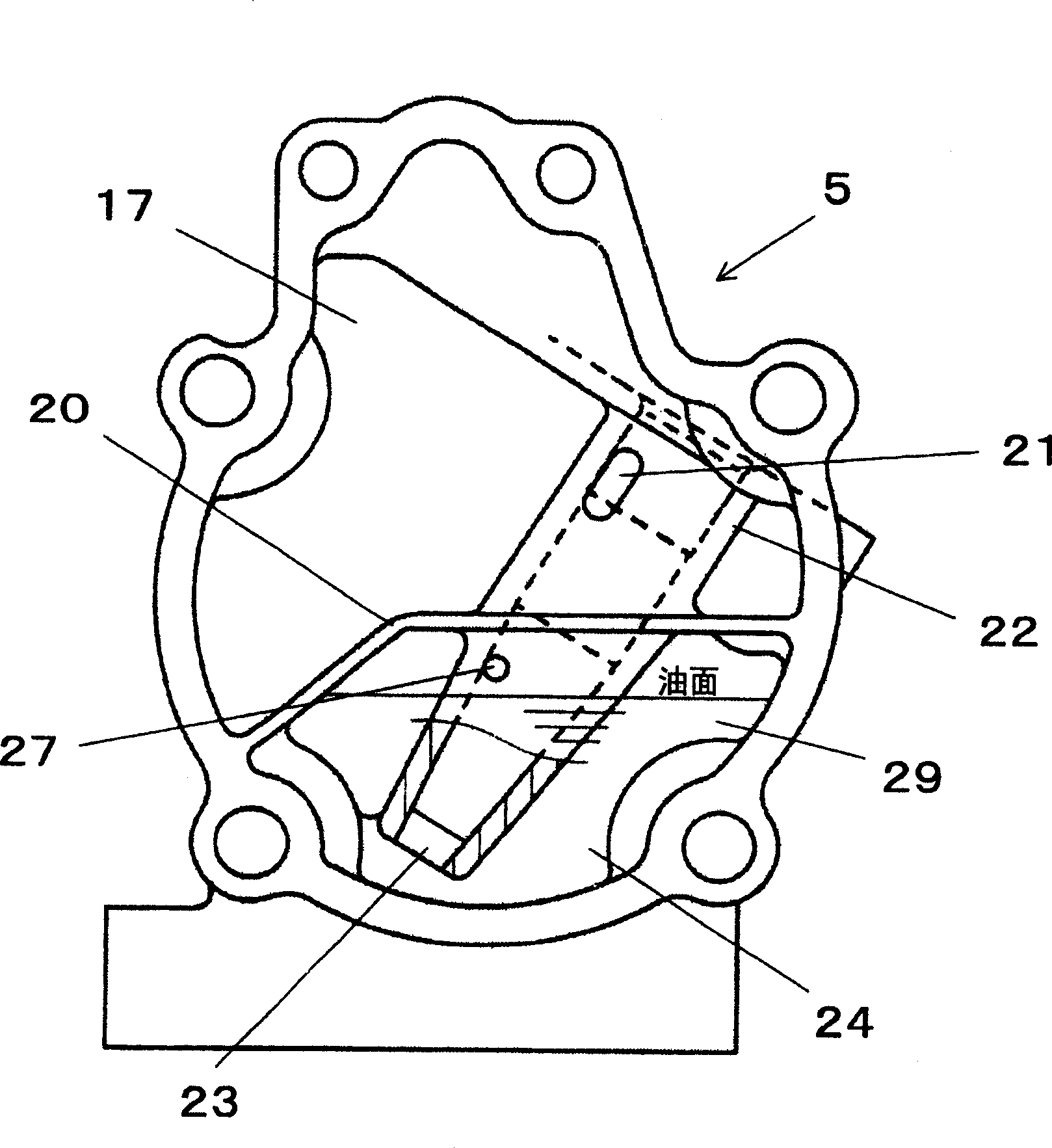

[0027] Embodiments when the present invention is applied to a vane rotary compressor will be described below with reference to the drawings.

[0028] exist Figure 1 to Figure 4 Among them, reference symbol 1 is a compressor, which includes: a cylinder 2 with a cylindrical inner wall; a front side plate 3 and a rear side plate 4 that block the front and rear openings of the cylinder 2; and are arranged side by side with the rear side plate 4 The hyperbaric chamber (hereinafter also referred to as the hyperbaric chamber cover 5.

[0029] The interior of the cylinder 2 is installed with a substantially cylindrical rotor 6 that can rotate freely. The rotor 6 is eccentric with respect to the axis of the cylinder 2, and a small gap is formed between part of its outer periphery and the inner wall of the cylinder 2. . The rotor 6 is provided with a drive shaft 7 integrated therewith, and the drive shaft 7 is installed in the front side plate 3 and the rear side plate 4 through bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com