Moulding frame used for powder compression moulding machine

A technology of press forming and mold base, applied in the direction of presses, manufacturing tools, etc., to reduce the height, improve the degree of automation and production efficiency, and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail with the following examples and drawings, but the embodiments of the present invention are not limited thereto.

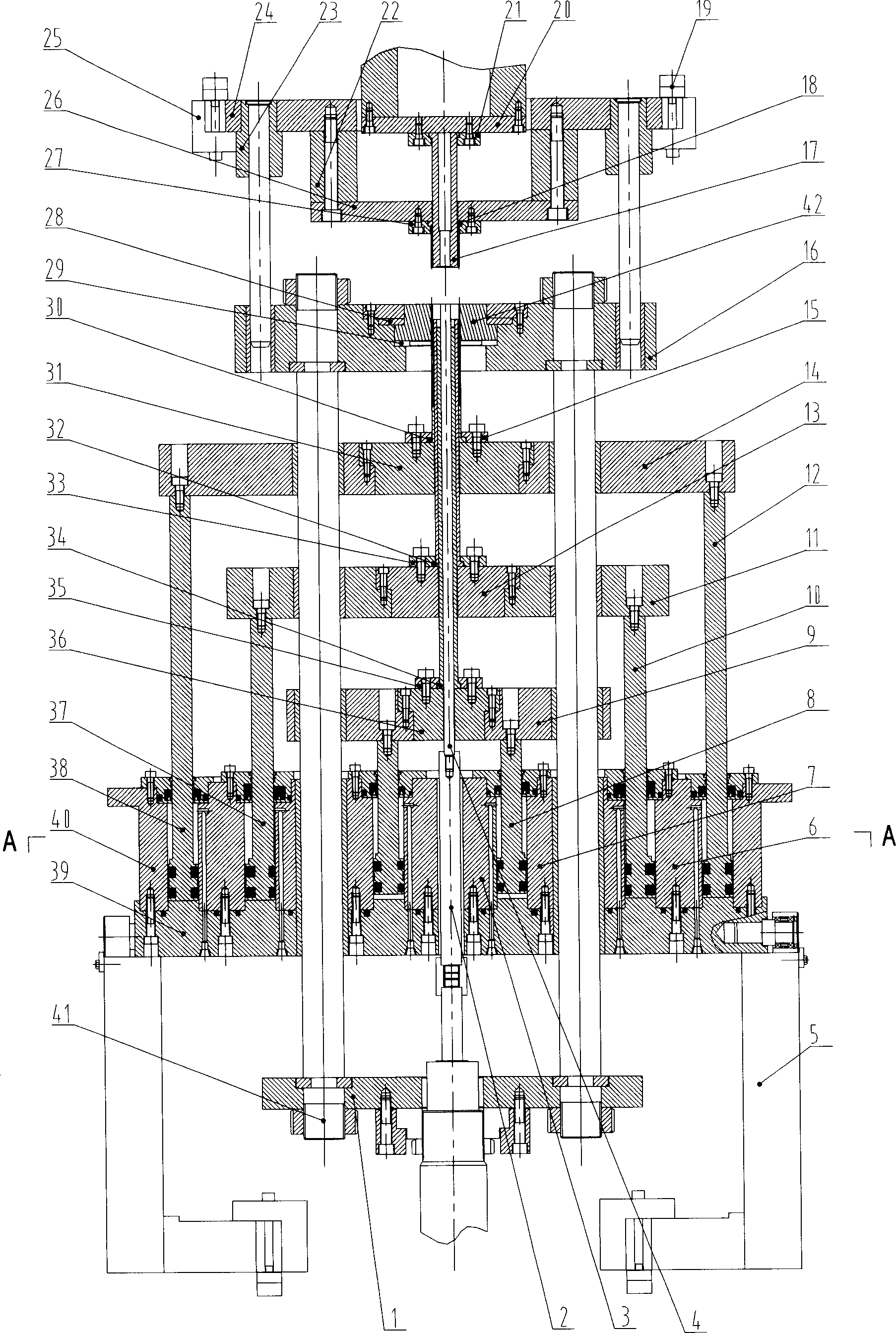

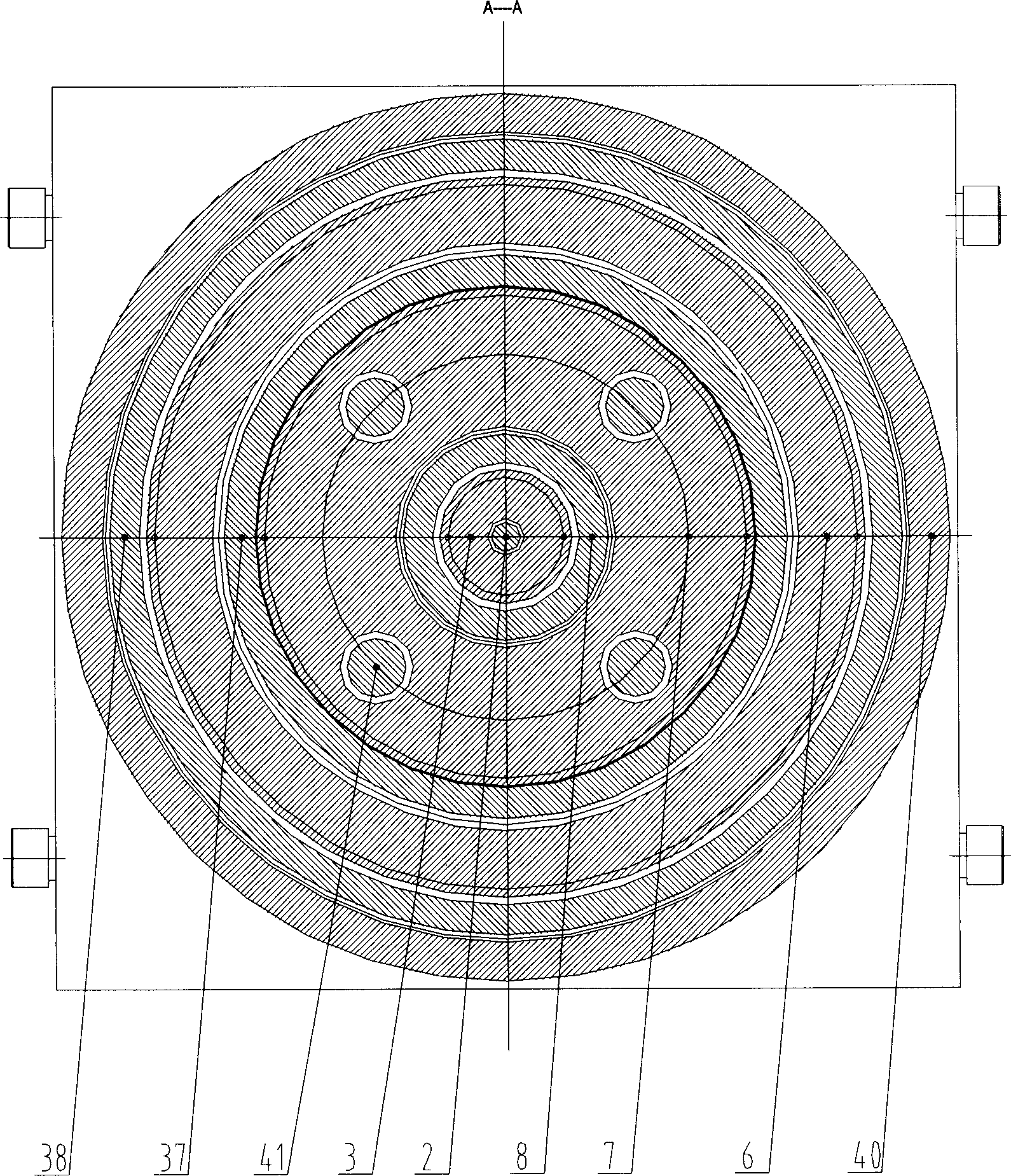

[0018] Such as figure 1 , figure 2 Shown, a structural form of the present invention, by figure 1 , figure 2 It can be seen that the three-layer template mold base for the powder compacting machine includes the following parts: connecting plate 1, connecting rod 2, inner wall of annular oil cylinder I 3, core rod 4, backing plate of mold base 5, outer wall of annular oil cylinder II 6, and annular oil cylinder I Outer wall 7, lower inner template ring driving rod 8, lower inner template 9, lower middle template ring driving rod 10, lower middle template 11, lower outer template ring driving rod 12, lower middle die punch connecting seat 13, lower outer template 14, Lower outer die stamping ring 15, female die seat 16, upper inner die punch 17, upper outer die punch 18, T-shaped block 19, upper inner die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com