Device for dissolving out aluminium oxide

A technology of alumina and dissolution rate, applied in alumina/aluminum hydroxide, inorganic chemistry, aluminum compounds, etc., can solve problems such as difficulty in output, and achieve the effect of improving the level of alumina technology and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

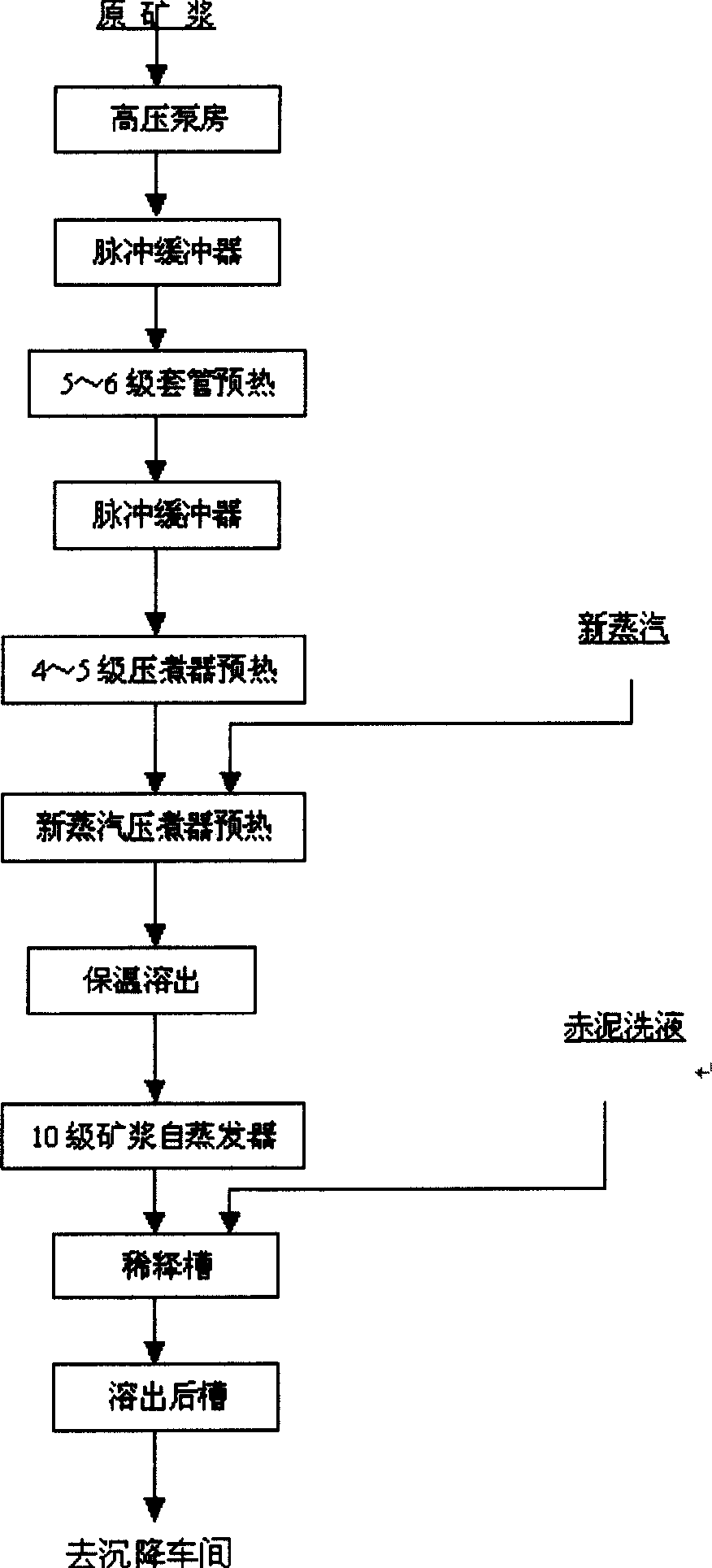

[0038] Embodiment of the present invention: according to the production capacity of alumina is 500kt / a, the following equipment is selected for matching:

[0039] ①High-pressure diaphragm pump: 2 sets of GEHO pumps are selected, the flow Q=480~550m3 / h, P=6.0~7.0Mpa;

[0040] ② Casing Preheater: Six-stage casing preheating is adopted, six casings per stage, each casing length is 90m, and the total casing length is 3240m; the specification of the inner casing is: D325×13~14, and the specification of the outer casing is: D402 ×9~10;

[0041] ③Pulse buffer: 2 sets, the pressure is 5.2Mpa and 7.0Mpa respectively, equipment specification: φ2.6×10m, volume 42m 3 ;

[0042] ④ Pressure cooker with heating tube bundle: 16 sets, design pressure 5.2Mpa, pressure cooker specification: φ3×18m, volume 100m 3 , heating area 610m 2 ;

[0043] ⑤ Pressure cooker: 5 sets, design pressure 5.2Mpa, pressure cooker specification: φ3×18m, volume 100m 3 ;

[0044] ⑥ Flash evaporator: 12 units in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com