Float load type oil recovering

An oil recovery and loading technology, which is used in floating buildings, water conservancy projects, and open-air water surface cleaning, etc., can solve problems such as the reduction of oil recovery rate, and achieve the effect of improving oil recovery rate and reducing height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

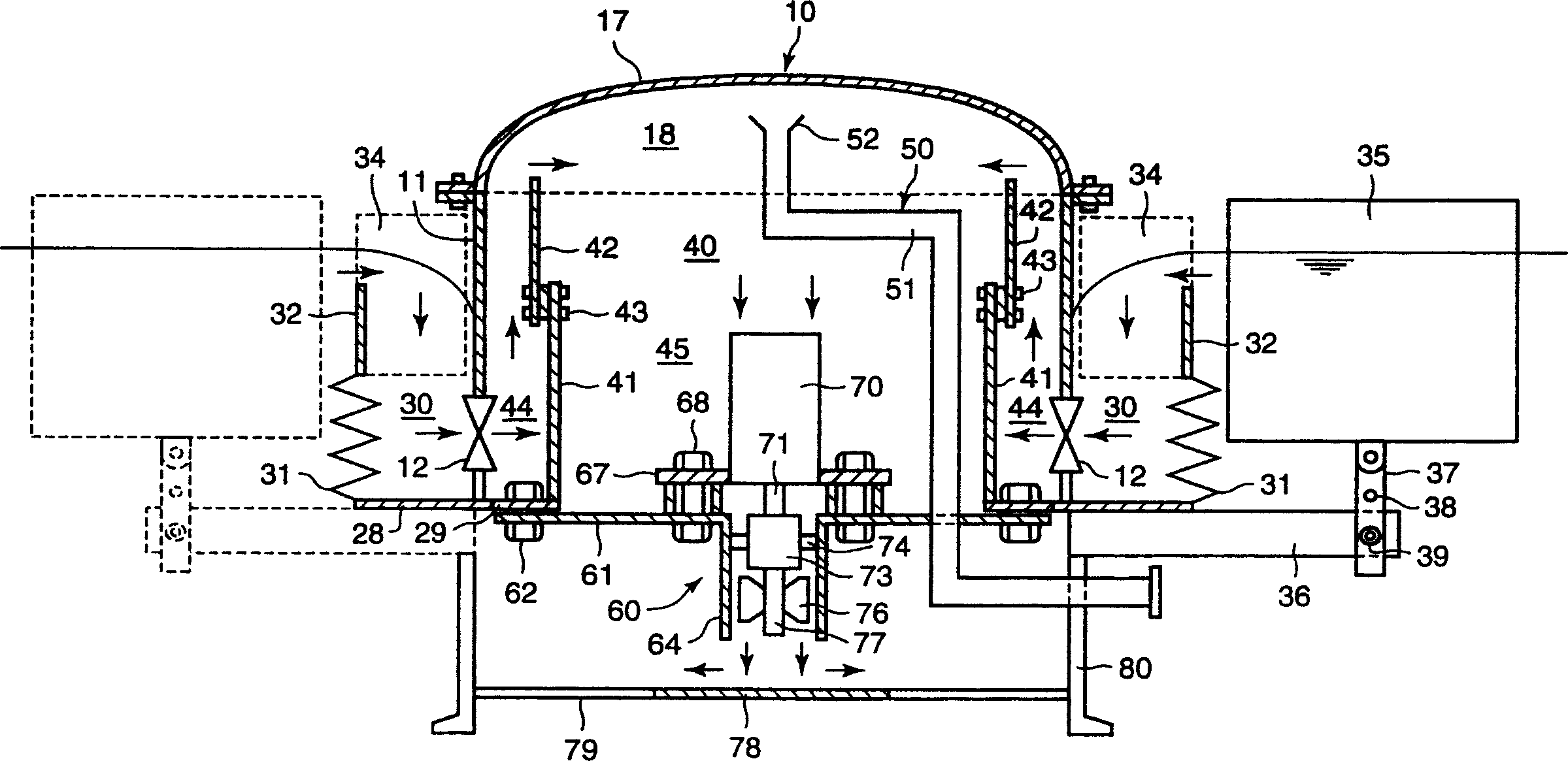

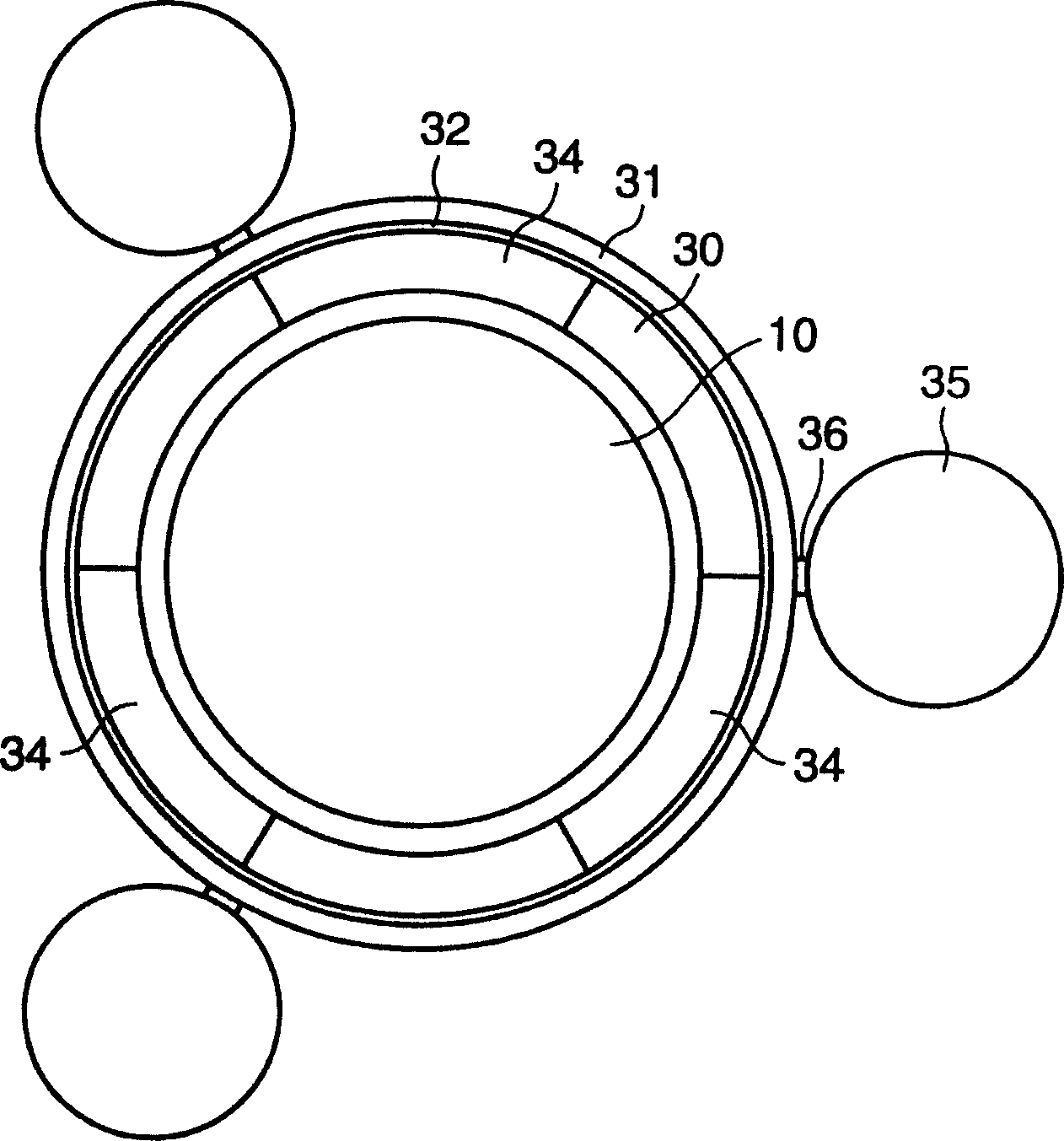

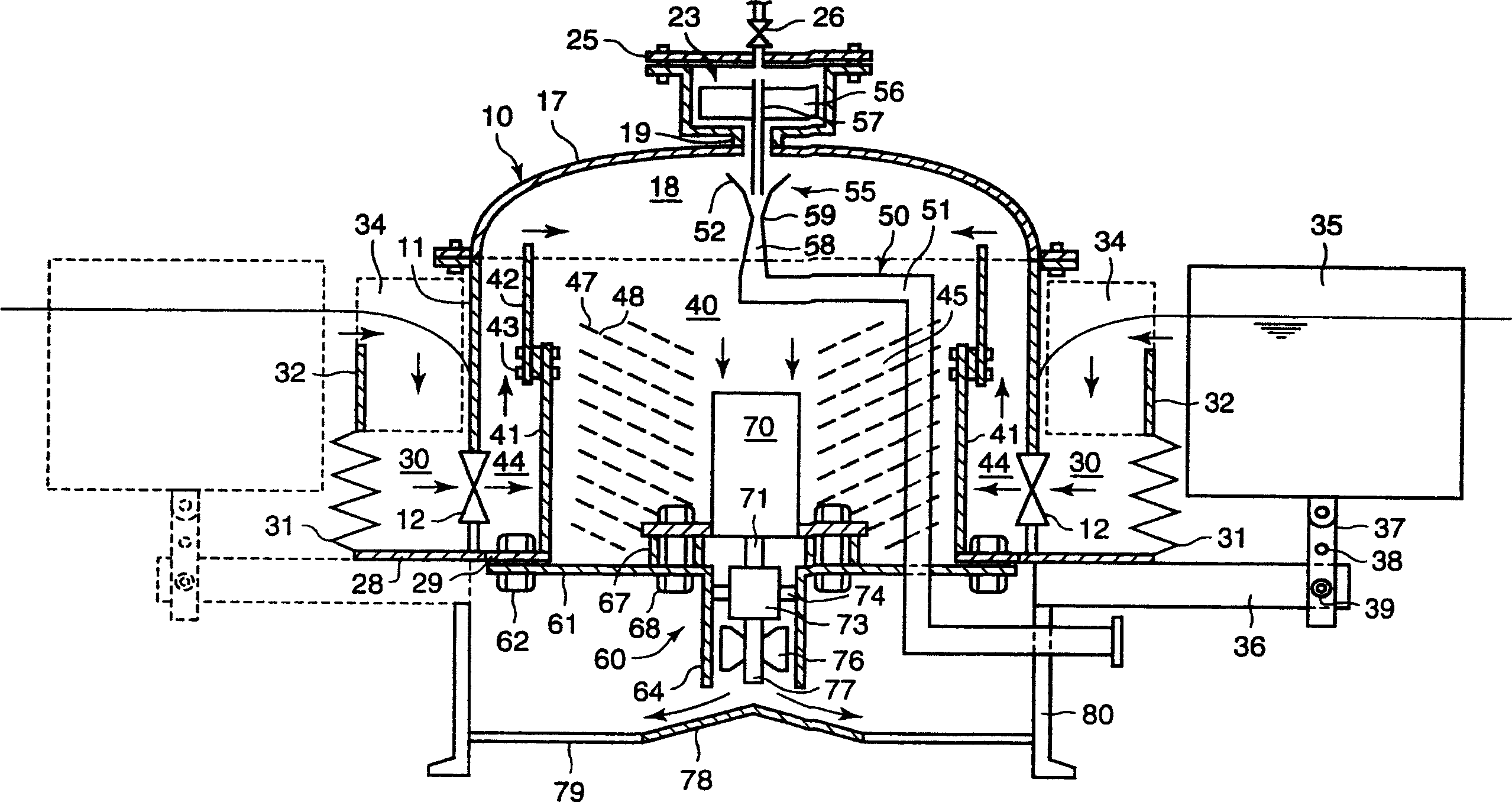

[0017] figure 1 and figure 2 represents the first form of the present invention, figure 1 To schematically represent a sectional view of an oil recovery unit, figure 2 for figure 1 Top view of the device shown. The oil recovery device is mainly composed of an oil-water separation chamber 10 , an oil-water inflow chamber 30 , an inner floating body 34 , an outer floating body 35 , an oil-water separation part 40 , an oil suction device 50 and a forced drainage device 60 .

[0018] The oil-water separation chamber 10 includes a cylindrical separation chamber main body 11 and a dome-shaped cover 17 attached to the top of the separation chamber main body 11 . Near the bottom of the main body 11 , a plurality of oil-water inlets 12 are provided at intervals along the circumferential direction. The oil-water inflow port 12 is located under the water surface to form a submerged weir. An oil reservoir 18 is formed inside the cover 17 . An annular bottom plate 28 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com