Intermediate frequency heating pipe plastic liner device

A heating device and steel pipe technology, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of low production efficiency, complex structure, and large equipment volume, and achieve high production efficiency, simplify the device structure, and reduce the size of the device. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

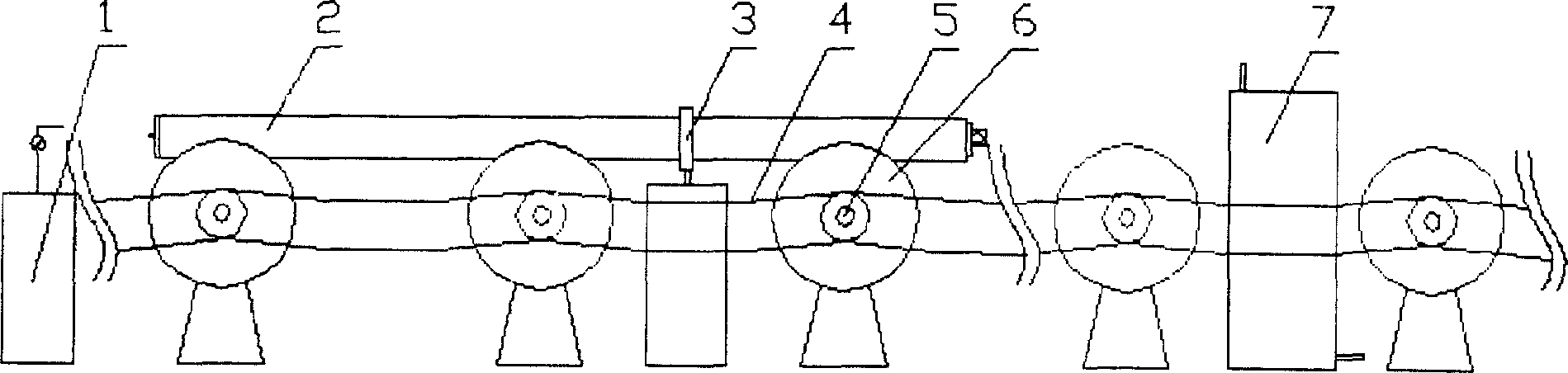

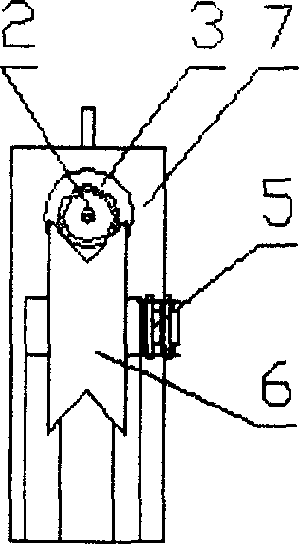

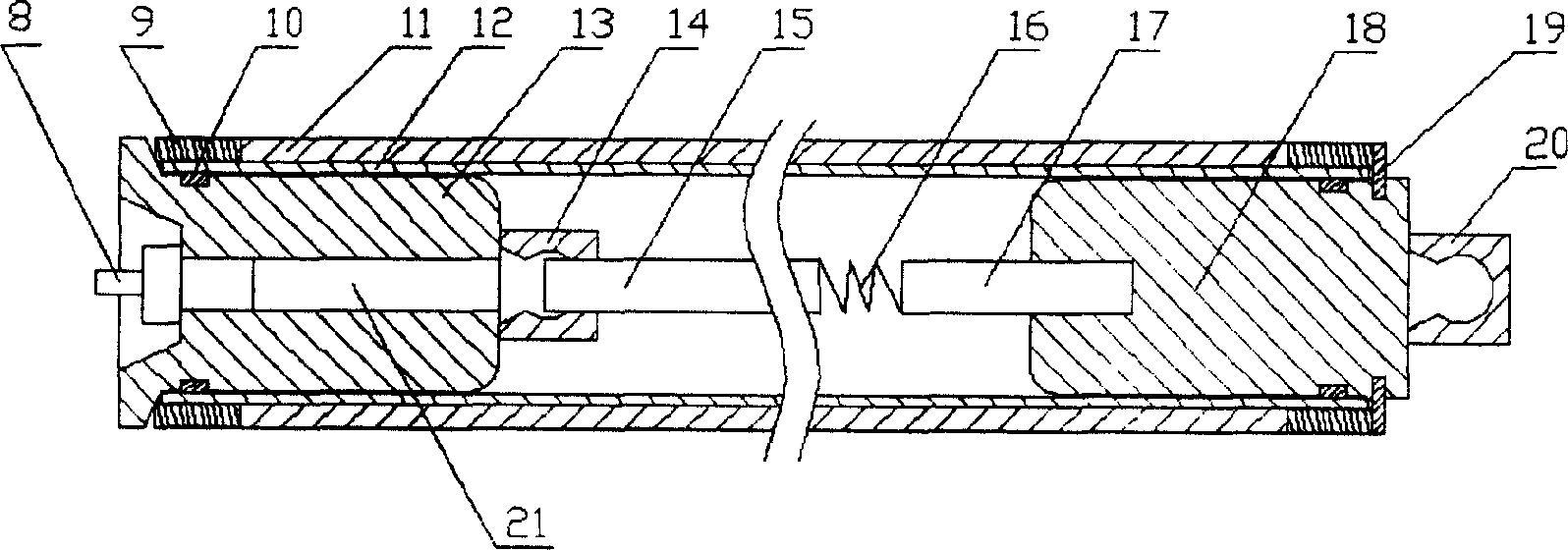

[0009] The present invention will be further described below with reference to the accompanying drawings.

[0010] A pair of self-locking sealing plugs 13, 18 are processed from steel. One of the end plugs 13 is in the shape of a flat cap bottle stopper, the outer diameter of the plug is slightly smaller than the inner diameter of the lined plastic pipe 12, the diameter of the flat cap of the plug body is equal to the outer diameter of the steel pipe 11, and an axial through hole 21 is opened in the plug body. The outer port of the axial through hole 21 is equipped with a self-sealing quick joint 8 for inflation, and a pull ring 14 is arranged on the end face of the plug body; The end is provided with a ring groove matched with the semicircular snap ring 19, a pull ring 20 is arranged on the outer end face of the straight plunger, and a tension spring connecting rod 17 made of steel bar is arranged in the center of the inner end face, and one end of the extension spring 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com