Hydrate slurry and its prepn. method

A technology of hydrate slurry and hydrate, which is applied in chemical instruments and methods, materials for heat exchange, etc., to achieve the effects of improving crystallization efficiency, rapid manufacturing process, and increased generation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

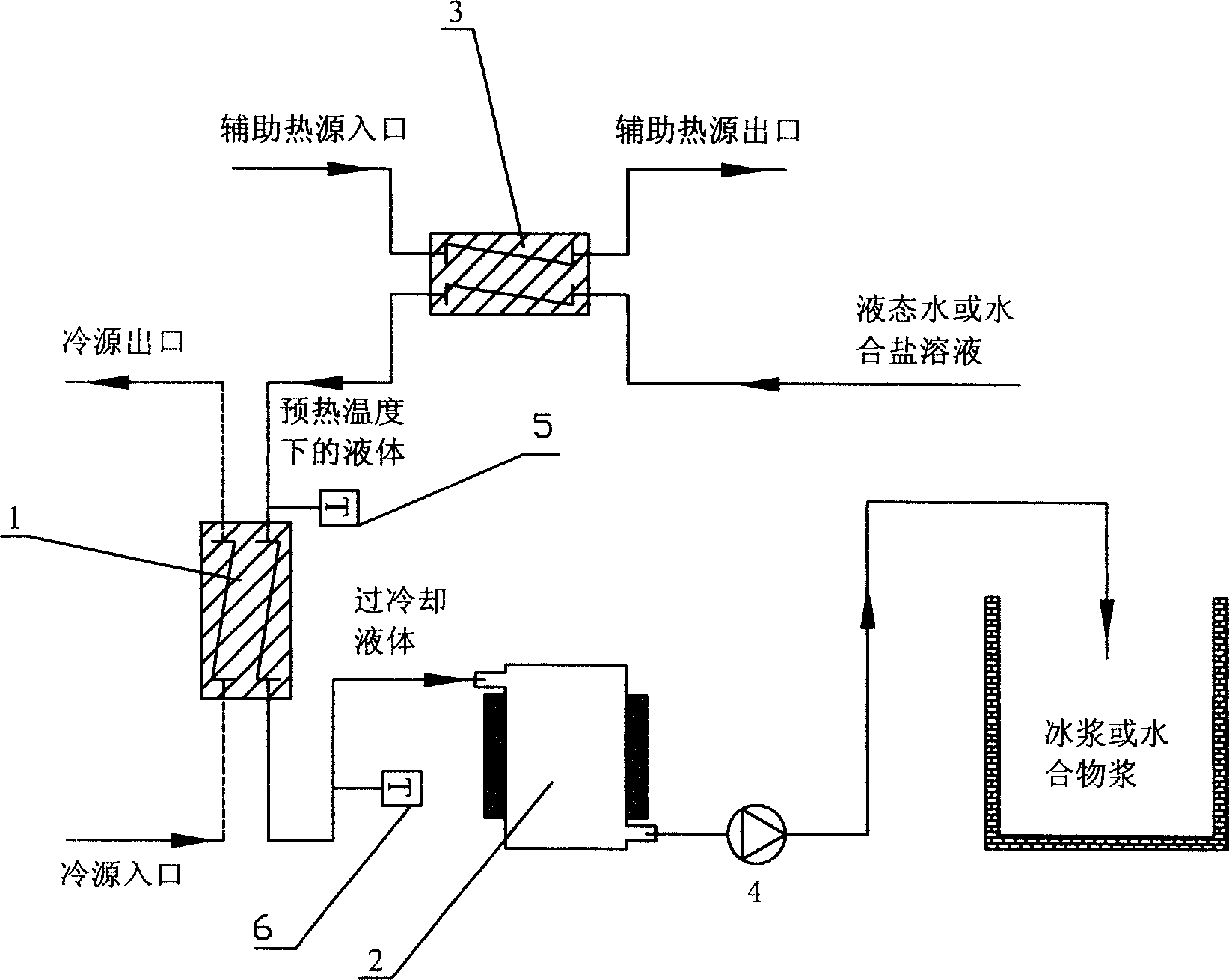

[0046] Such as figure 1 As shown, the preparation method of the hydrate slurry of the present invention uses a preheater 3, a supercooling heat exchanger 1, an ultrasonic supercooling removal device 2 and a delivery pump 4 connected end to end in sequence, and the preheater 3 and the supercooling heat exchanger A temperature sensor 5 is installed between 1, and a temperature sensor 6 is also installed between the supercooling heat exchanger 1 and the ultrasonic supercooling release device 2.

[0047] The subcooling heat exchanger 1 is a plate heat exchanger, and the preheater 3 is a plate heat exchanger or a shell-and-tube heat exchanger or a casing heat exchanger.

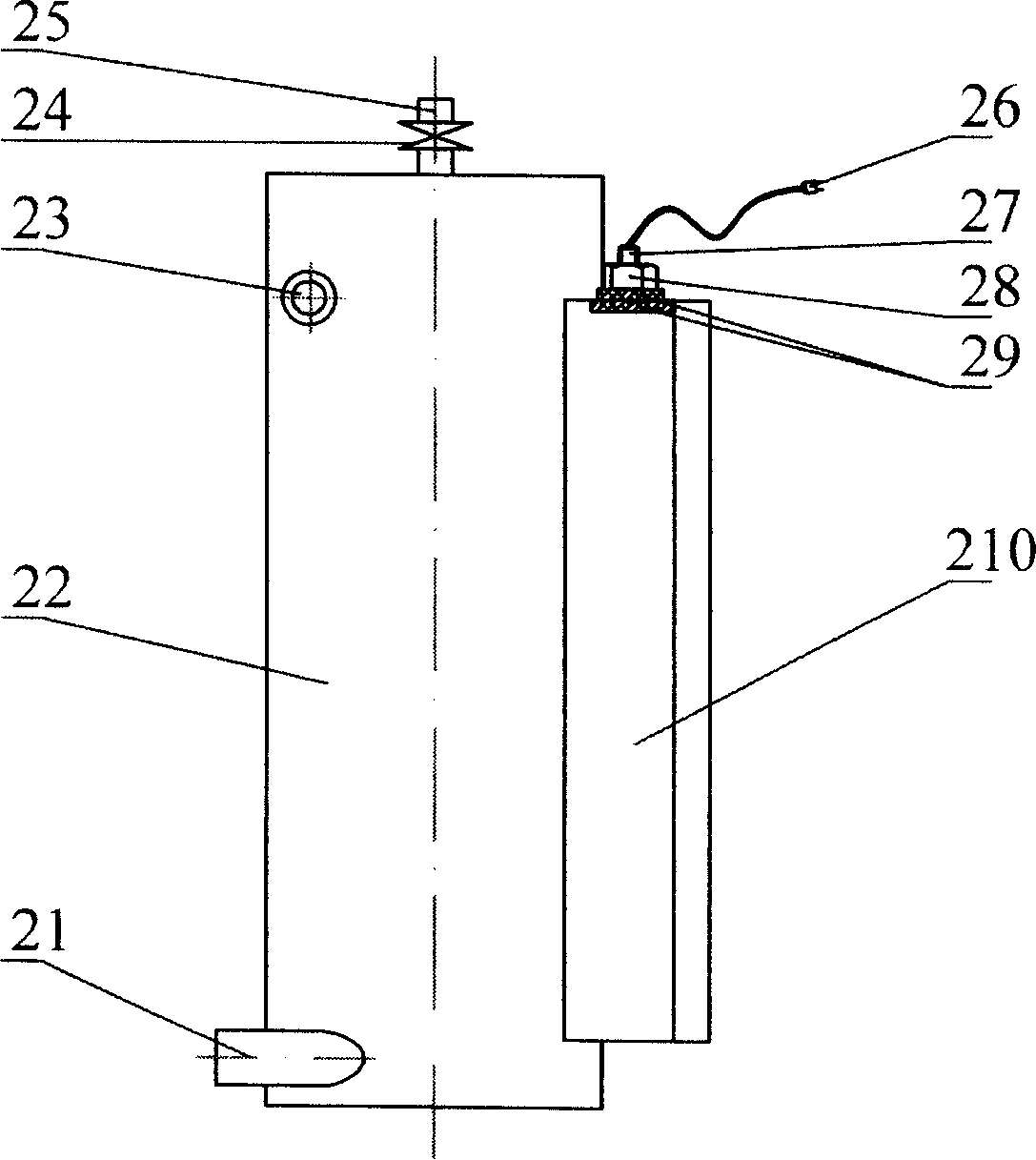

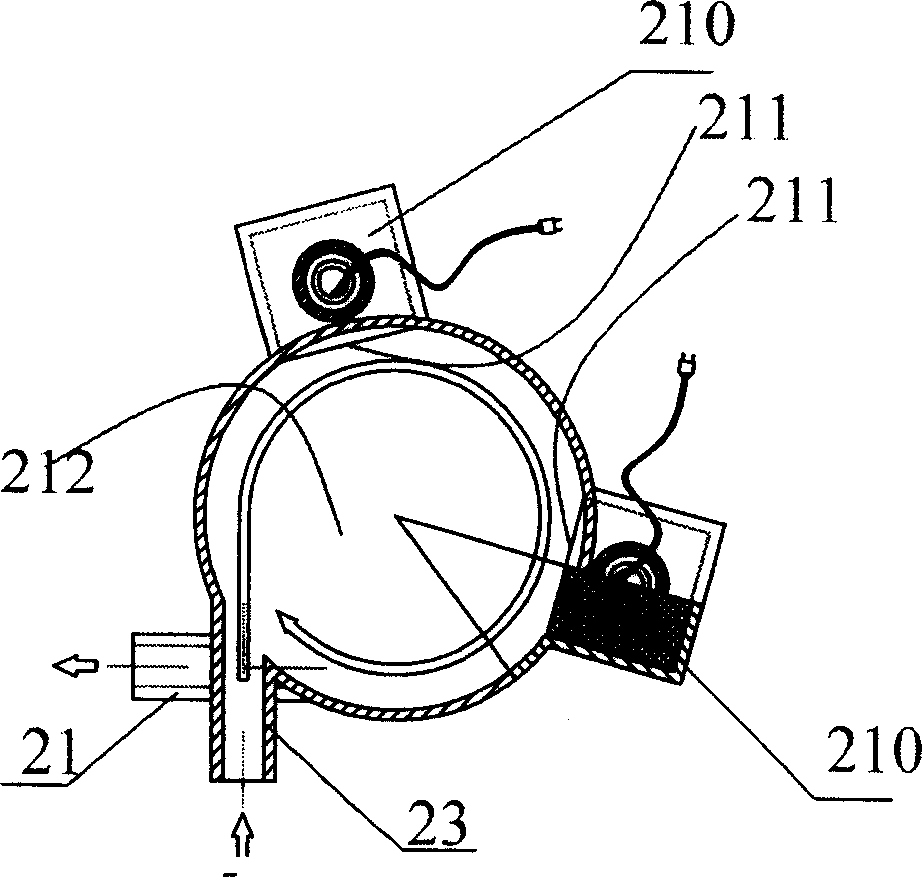

[0048] Such as figure 2 , image 3As shown, the ultrasonic supercooling release device 2 in the present invention includes a housing 22 and two ultrasonic vibrator boxes 210 packaged inside the housing 22, the housing 22 and the ultrasonic vibrator boxes 210 form a cylindrical inner cavity 212, two The ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com